Method for preparing carbon coated hexagonal boron nitride

A technology of hexagonal boron nitride and carbon coating, applied in the preparation/purification of carbon, chemical instruments and methods, nitrogen compounds, etc., can solve the problems of easy agglomeration, large specific surface energy of BN nanoparticles, etc. , low price, easy availability of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

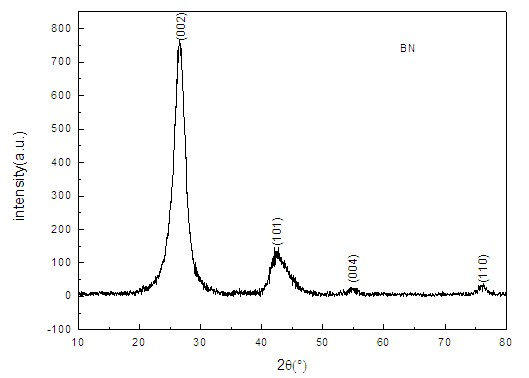

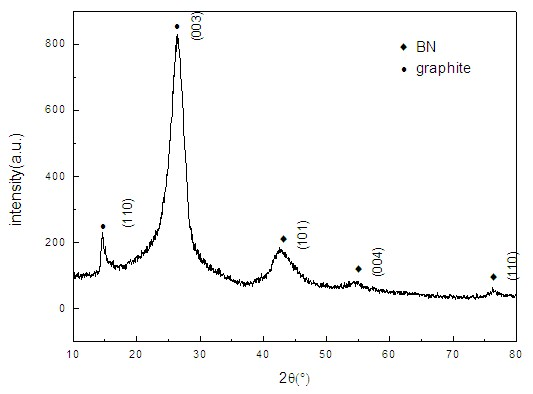

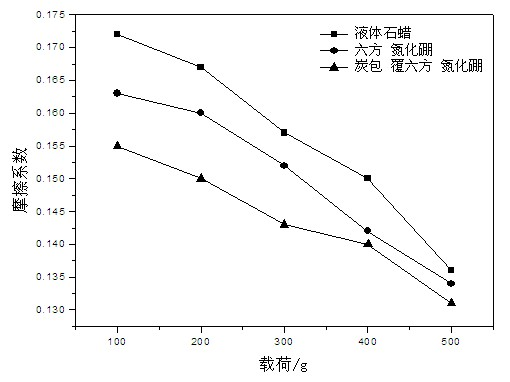

[0017] Take boric acid and urea at a molar ratio of 2:3, mix them evenly and put them into the ark, place them in a tube furnace and raise the temperature to 800°C for 1 hour at a rate of 5°C / min to obtain hexagonal boron nitride. Carry out x-ray diffraction analysis to product, the result is as follows figure 1 shown. The obtained hexagonal boron nitride was placed in the maleic anhydride ethylene octene graft copolymer dissolved in tetrahydrofuran, stirred evenly, extracted with absolute ethanol, filtered with suction, and dried in an oven at 60°C for 5 hours. Transfer the above dried product into a stainless steel reaction kettle, seal it and place it in a tube furnace, raise the temperature to 600°C at a rate of 5 / min, keep it warm for 1 hour, and then cool it naturally to obtain carbon-coated hexagonal boron nitride. X-ray diffraction analysis was carried out on it, and the results were as follows figure 2 As shown, it can be seen from the figure that carbon-coated hex...

Embodiment 2

[0019] Take boric acid and urea at a molar ratio of 2:3, mix them evenly and put them into the ark, place them in a tube furnace and raise the temperature to 850°C for 1 hour at a rate of 10°C / min to obtain hexagonal boron nitride. The obtained hexagonal boron nitride was placed in the maleic anhydride ethylene octene graft copolymer dissolved in tetrahydrofuran, stirred evenly, extracted with absolute ethanol, filtered with suction, and dried in an oven at 70°C for 4.5 hours. Transfer the above dried product into a stainless steel reaction kettle, seal it and place it in a tube furnace, raise the temperature to 600°C at a rate of 5°C / min, keep it warm for 1 hour, and then cool it down naturally to obtain carbon-coated hexagonal boron nitride.

Embodiment 3

[0021] Take boric acid and urea at a molar ratio of 2:3, mix them evenly and put them into the ark, place them in a tube furnace and raise the temperature to 800°C for 1 hour at a rate of 10°C / min to obtain hexagonal boron nitride. The obtained hexagonal boron nitride was placed in the maleic anhydride ethylene octene graft copolymer dissolved in tetrahydrofuran, stirred evenly, extracted with absolute ethanol, filtered with suction, and dried in an oven at 80°C for 5 hours. Transfer the above dried product into a stainless steel reaction kettle, seal it and place it in a tube furnace, raise the temperature to 600°C at a rate of 5°C / min, keep it warm for 1 hour, and then cool it down naturally to obtain carbon-coated hexagonal boron nitride.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com