Organic and inorganic compound fertilizer special for tobaccos

An inorganic composite and tobacco technology, applied in the direction of organic fertilizers, organic fertilizer preparation, fertilizer mixtures, etc., can solve the problems of large differences in effective nutrients and release patterns, limitations in the quantity and quality of resources, and poor fertilizer application effects. Achieve the effects of improving the balanced supply of nutrients, improving disease resistance and drought resistance, and promoting the root development of tobacco plants

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

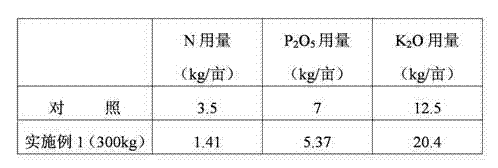

Embodiment 1

[0025] The preparation method of the decomposed straw is as follows: firstly crush wheat straw and rice straw, the particle size of the crushed straw is 2-5 cm, adjust the water content of the crushed straw to 55-60%, and then add 1.5 % urea and decomposing agent (HM decomposing agent produced by Henan Hebi Henglongtai Bioengineering Co., Ltd.) accounting for 5‰ of straw weight, stir evenly, stack and retting, the stacking volume> 15m 3 , turn the stack once every 15 days after stacking. When the daily average temperature is > 10°C, the stacking retting time is 60-80 days. When the daily average temperature is 5-10°C, the stacking retting time is 80-100 days. days, decomposed straw was obtained after stacking and retting.

[0026] The preparation method of the decomposed tobacco waste material is as follows: firstly, the uncured tobacco leaves, fireworks and tobacco rods produced in the tobacco leaf production process are crushed, the particle size of the crushed materials is ...

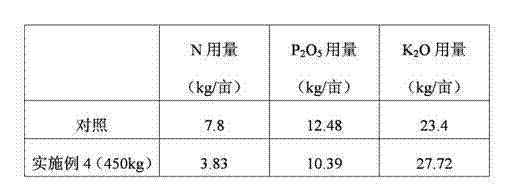

Embodiment 2

[0033] The special organic-inorganic compound fertilizer for tobacco of the present invention is represented by weight percent. The organic-inorganic compound fertilizer is composed of 40% decomposed straw, 24% decomposed tobacco waste, 6.5% cake fertilizer, 0.04% amino acid, 5% potassium nitrate, and potassium sulfate. 10%, ammonium dihydrogen phosphate 2.5%, ammonium bicarbonate 2.0%, urea 0.15%, phosphate fertilizer 7%, ammonium molybdate 0.07%, boric acid 0.2%, zinc sulfate 1.2% and magnesium sulfate 1.34%.

[0034] The method for preparing the decomposed straw is different from that of Example 1 in that firstly the corn straw and the rice straw are crushed, and then 2% of the straw weight of urea and 7‰ of the straw weight of the decomposing agent are added.

[0035] The preparation method of the decomposed tobacco waste material is different from Example 1 in that: firstly, the uncurable tobacco leaves, fireworks, axillary buds and tobacco rods produced in the tobacco lea...

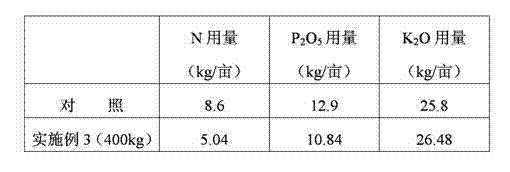

Embodiment 3

[0038] The special organic-inorganic compound fertilizer for tobacco of the present invention is represented by weight percent. The organic-inorganic compound fertilizer is composed of 44% decomposed straw, 20% decomposed tobacco waste, 10% cake fertilizer, 0.05% amino acid, 4% potassium nitrate, and potassium sulfate. 9%, ammonium dihydrogen phosphate 2.0%, ammonium bicarbonate 1.5%, urea 0.34%, phosphate fertilizer 6.5%, ammonium molybdate 0.01%, borax 0.3%, zinc sulfate 1.0% and magnesium sulfate 1.3%.

[0039] The method for preparing the decomposed straw is different from that of Example 1 in that firstly the corn straw and the wheat straw are crushed, and then 1% of the straw weight of urea and 3‰ of the straw weight of the decomposing agent are added.

[0040] The preparation method of the decomposed tobacco waste material is different from Example 1 in that: first, the uncured tobacco leaves and tobacco rods produced in the tobacco leaf production process are pulverized...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com