Dialkyl ether disulfonate surfactant and preparation method thereof

The technology of surfactant and bissulfonate is applied in the directions of sulfonate preparation, chemical instrument and method, drilling composition, etc., and can solve the problems of not being able to resist high salt and high calcium and magnesium ions, etc. To achieve the effect of convenient operation, simple preparation method and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

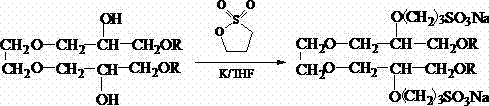

Method used

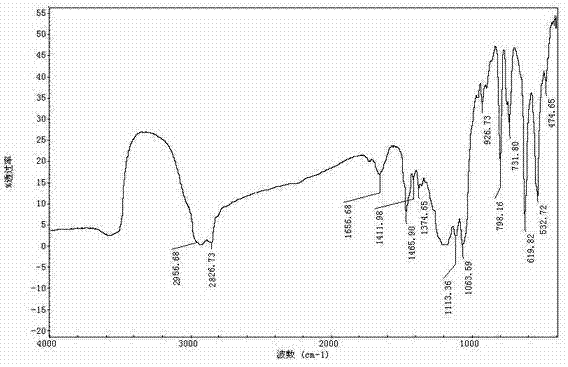

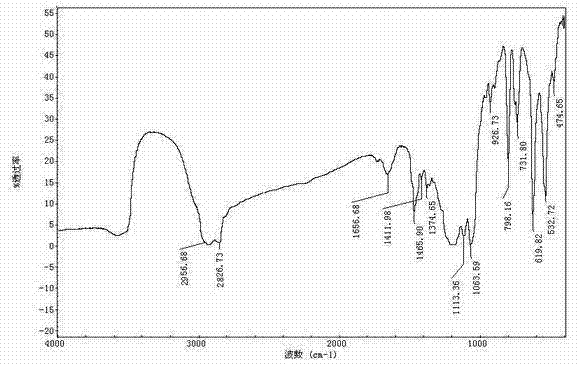

Image

Examples

Embodiment 1

[0026] (1) Etherification reaction In a three-necked flask, first add 0.5 mol of ethylene glycol, then add a phase transfer catalyst of boron trifluoride ether 0.007 mol, and then slowly add 1.8 mol of epichlorohydrin, the addition is complete, and the reaction lasts for 8 h After the reaction, the system was cooled to room temperature, and then 50ml of 0.1mol / L sodium hydroxide ethanol solution was slowly added dropwise. After the dropwise addition, the reaction was continued at 25°C for 6 h. After the reaction was completed, the sodium chloride solid produced in the system was removed by suction filtration, and the ethanol and excess epichlorohydrin were distilled off by a rotary evaporator under reduced pressure. The distilled product was dissolved in saturated saline, extracted with petroleum ether, and the combined oil phase, distill off the solvent to obtain viscous transparent liquid ethylene glycol dioxypropylene ether;

[0027] (2) Ring-opening reaction Heat up the mi...

Embodiment 2

[0030] The critical micelle concentration (cmc) and surface tension of surfactants are important parameters for evaluating the performance of surfactants. The present invention adopts full-range rotary drop meter / interfacial tensiometer TX-500C to measure the performance of product, and experimental data is listed in table 1:

[0031] Table 1 Surface properties of different sulfonate surfactants (40°C)

[0032] Surfactant CMC / mmol.L -1 gamma cmc / mN m -1 TTSS-2-12 0.050 27.7 TTSS-2-14 0.0064 26.2 TTSS-2-16 0.0021 24.8 SDS 9.7 34.1

[0033] It can be seen from the above table that the cmc of TTSS-2-n series surfactants is 1-3 orders of magnitude lower than that of the same type of surfactants, such as sodium dodecylsulfonate (SDS), and the surface tension is also higher than that of SDS Smaller, with higher surface activity.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com