Barium zirconate titanate-barium calciate titanate (BZT-BCT) ceramic modified by doping of lanthanum oxide and preparation method for same

A technology of barium calcium zirconate titanate and zirconia balls, which is applied in the field of functional ceramics, can solve the problems of adjusting the dielectric constant, withstand voltage characteristics, temperature stability of barium strontium titanate ceramics, and limiting the application of adjustable capacitor devices. Achieve superior temperature stability, high tuning rate, and low dielectric loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

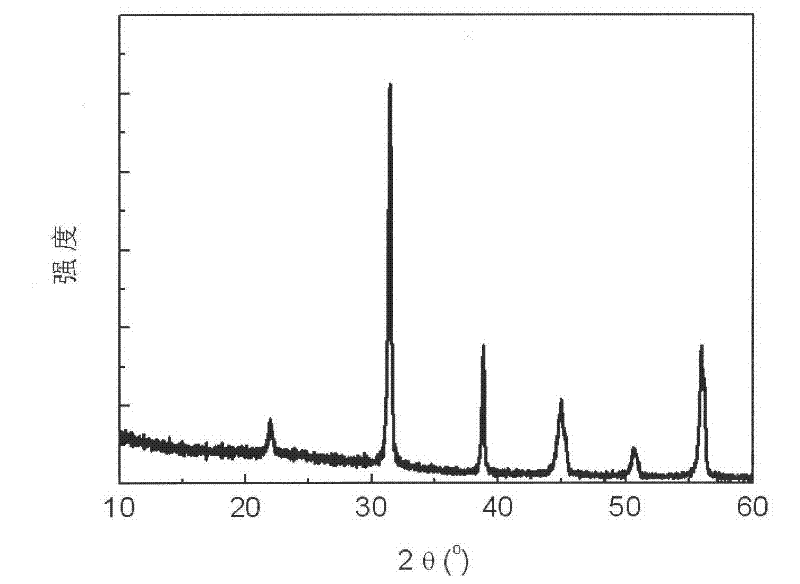

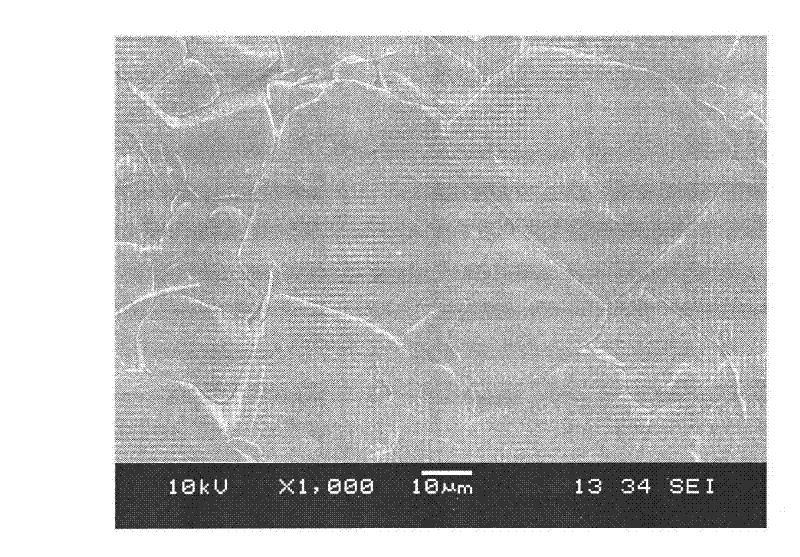

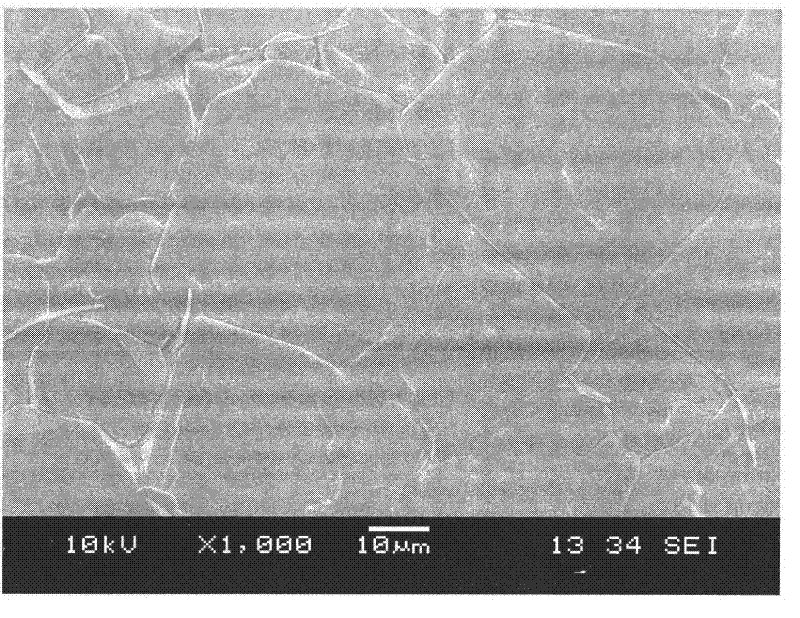

[0016] Piezoelectric ceramic material, its molecular structure expression is: Ba 0.98 La 0.02 Ca 0.075 Zr 0.8995 Ti 0.0995 o 3

[0017] The steps are: put analytically pure barium carbonate, calcium carbonate, zirconia, titanium oxide and lanthanum oxide in the stoichiometric ratio Ba 1-x La x Ca 0.075 (Zr 0.9 Ti 0.1 ) 1-x / 4 o 3 Carry out batching, where x=0.02; put the prepared raw materials into the ball mill tank, add zirconia balls and absolute ethanol, the quality of the added zirconia balls is twice the mass of the raw materials, and use wet milling method for ball milling and mixing 4 hour, the rotation speed is 250 rpm; take it out and place it in an oven to dry at 80°C; put the dried powder into a crucible, raise the temperature to 1000°C at a rate of 1°C / min, and keep it warm for 1 hour; Put the calcined powder into a ball mill jar, add zirconia balls and absolute ethanol, the quality of the added zirconia balls is 4 times the mass of the raw material, an...

Embodiment 2

[0019] Piezoelectric ceramic material, its molecular structure expression is: Ba 0.96 La 0.04 Ca 0.075 Zr 0.891 Ti 0.099 o 3

[0020] The steps are: analyze pure barium carbonate, calcium carbonate, zirconia, titanium oxide and lanthanum oxide by stoichiometric Ba 1-x La x Ca 0.075 (Zr 0.9 Ti 0.1 ) 1-x / 4 o 3Carry out batching, wherein x=0.04; Put the prepared raw materials into the ball mill tank, add zirconia balls and absolute ethanol, the quality of the added zirconia balls is 4 times of the raw material quality, and use the wet milling method to carry out ball milling and mixing for 8 Hours, the rotation speed is 300 rpm; take it out and place it in an oven to dry at 100°C; put the dried powder into a crucible, raise the temperature to 1100°C at a rate of 3°C / min, and keep it warm for 3 hours; Put the calcined powder into a ball mill jar, add zirconia balls and absolute ethanol, the quality of the added zirconia balls is 5 times the mass of the raw material, an...

Embodiment 3

[0022] Piezoelectric ceramic material, its molecular structure expression is: Ba 0.94 La 0.06 Ca 0.075 Zr 0.8865 Ti 0.0985 o 3

[0023] The steps are: analyze pure barium carbonate, calcium carbonate, zirconia, titanium oxide and lanthanum oxide by stoichiometric Ba 1-x La x Ca 0.075 (Zr 0.9 Ti 0.1 ) 1-x / 4 o 3 Carry out batching, wherein x=0.06; Put the prepared raw material in the ball mill tank, add zirconia balls and absolute ethanol, the quality of the added zirconia balls is 7 times of the raw material quality, and adopt wet milling method to carry out ball milling and mixing for 10 Hours, the rotation speed is 350 rpm; take it out and place it in an oven to dry at 120°C; put the dried powder into a crucible, raise the temperature to 1150°C at a rate of 3°C / min, and keep it warm for 4 hours; Put the calcined powder into a ball mill jar, add zirconia balls and absolute ethanol, the quality of the added zirconia balls is 7 times the mass of the raw material, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com