Fiber Raman yellow laser based on main oscillation power amplifier

A technology for power amplifiers and lasers, applied in the direction of laser scattering effect, structure/shape of active medium, etc., can solve the problems of complex equipment, low yellow light power, weakening of signal spectral lines, etc., and meet the requirements of reducing heat resistance. , High second harmonic conversion efficiency, beneficial control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

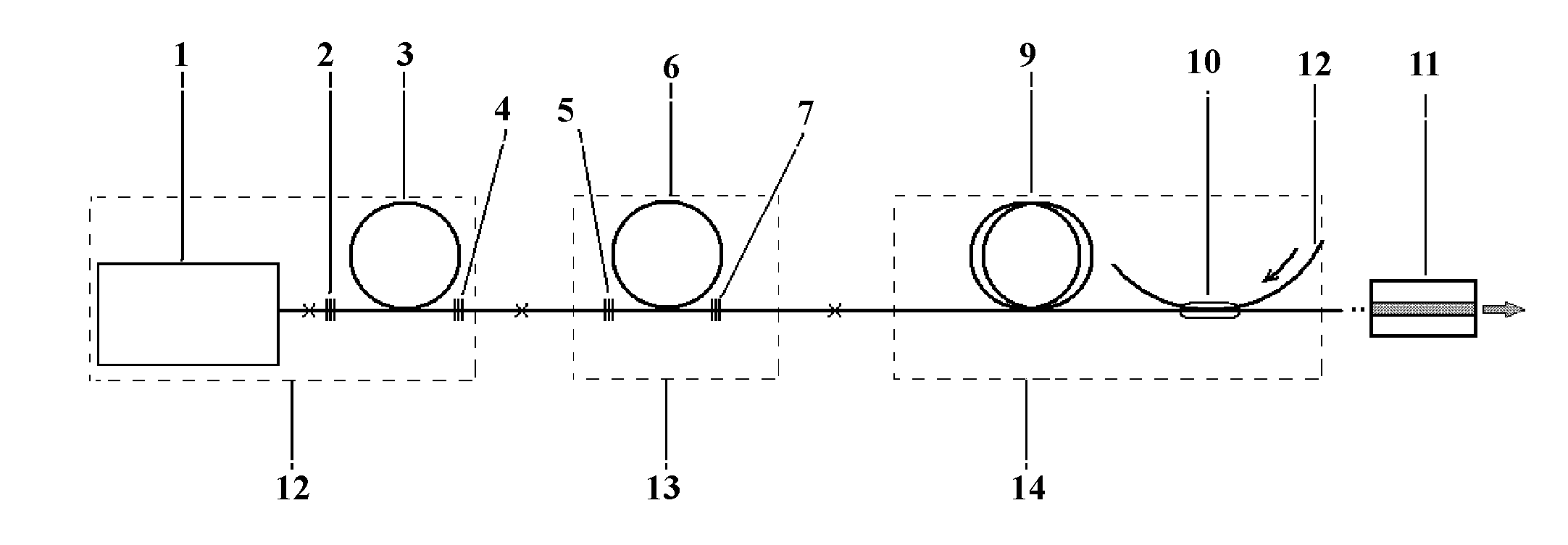

[0031] Such as figure 1 As shown, the 589nm fiber Raman yellow laser based on the main oscillator power amplifier, including semiconductor laser pump source, ytterbium-doped double-clad fiber, fiber grating, germanium-doped silicon fiber, frequency doubling crystal, multimode pump combiner It is characterized in that all components of the system adopt fiber coupling or direct fusion splicing, and the sequence is semiconductor laser, first fiber grating, polarization-maintaining ytterbium-doped double-clad fiber, second fiber grating, third fiber grating, first germanium-doped silicon An optical fiber, a fourth fiber grating, a second germanium-doped silicon fiber, a multimode pump beam combiner, a pump fiber laser, and a frequency doubling crystal.

[0032] The semiconductor laser pumping source 1 adopts a semiconductor laser with a wavelength of 915nm, the output of the pigtail, the fiber size is 50 / 125μm, the maximum output power of the laser is 10W, and it is cooled by air ...

Embodiment 2

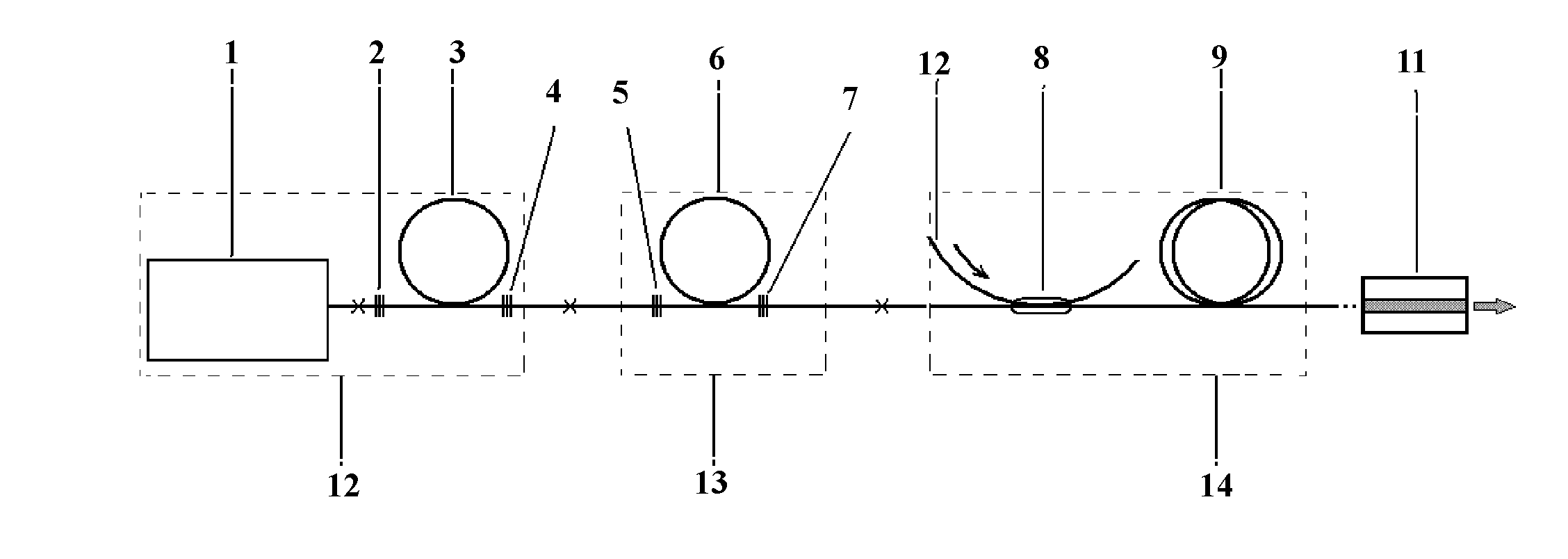

[0042] In the 1178nm laser Raman amplification part, a 1120nm fiber laser 12 is used to forward pump the germanium-doped silicon fiber 9, and the other parts are consistent with embodiment 1, and its structural representation is as follows figure 2 shown.

Embodiment 3

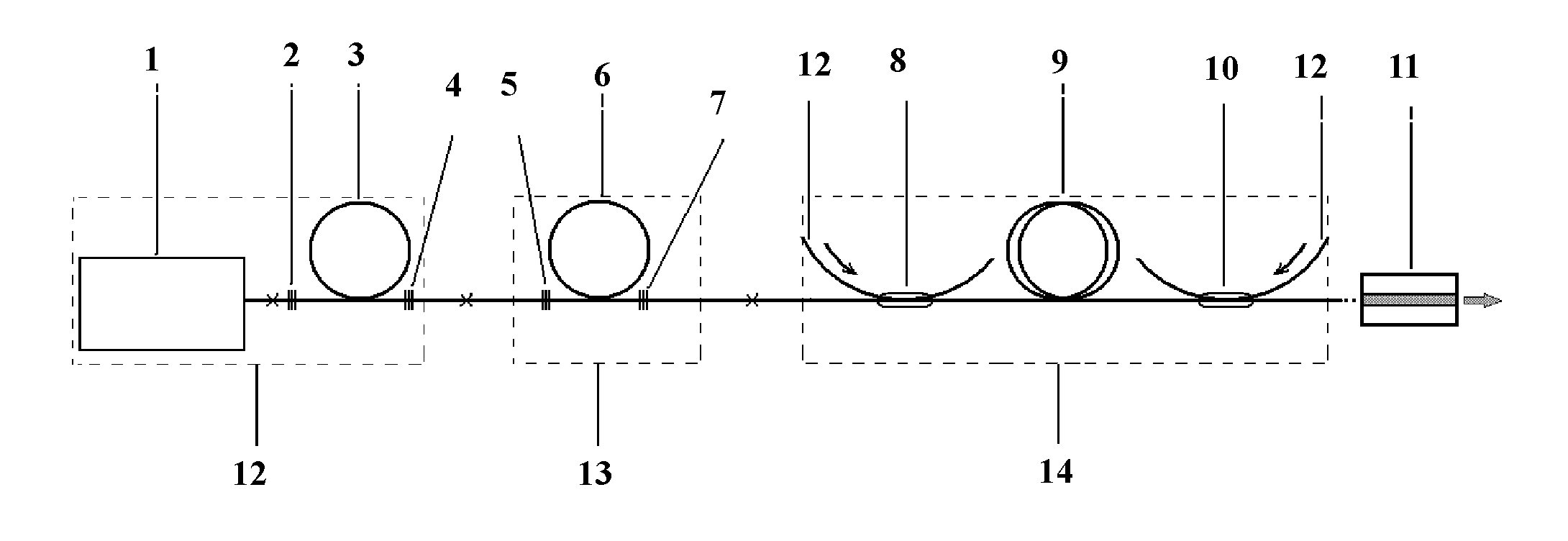

[0044] In the 1178nm laser Raman amplification part, the bidirectional pumping mode is adopted, that is, two 1120nm fiber lasers 12 are used to bidirectionally pump the germanium-doped silicon fiber 9, and the other parts are consistent with embodiment 1, and its structural diagram is as follows image 3 shown.

[0045] The present invention is mainly used in the preparation of yellow fiber lasers. Above, 598nm fiber Raman yellow light laser is used as an example, and the parameters of the main components of the present invention are given, but the present invention is not limited to 598nm fiber Raman yellow light lasers.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com