Method used for preparing hydroxy manganese oxide superfine single crystal nanometer line

A manganese oxyhydroxide, single-crystal nanotechnology, applied in chemical instruments and methods, nanotechnology, inorganic chemistry, etc., can solve the problems of small specific surface area, large material size, rare, etc., and achieve stable product quality and low cost. , the effect of good process repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

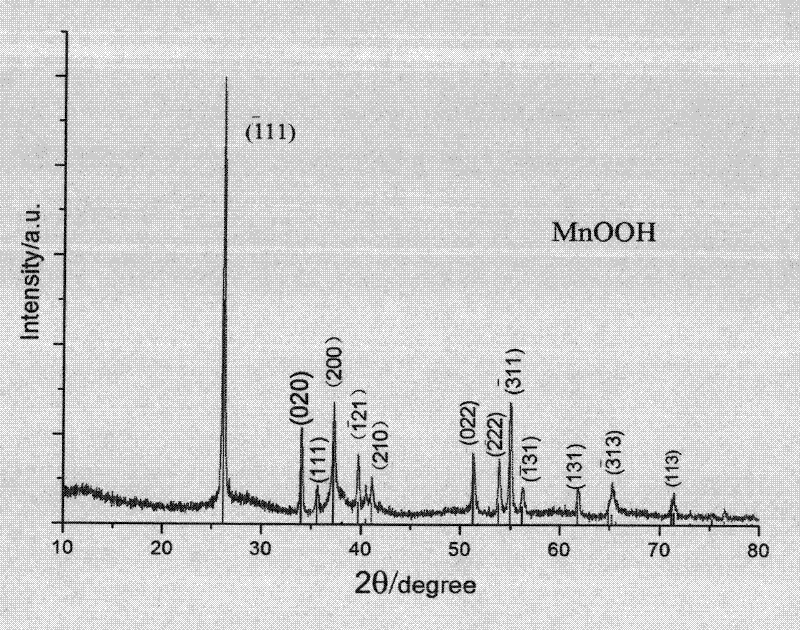

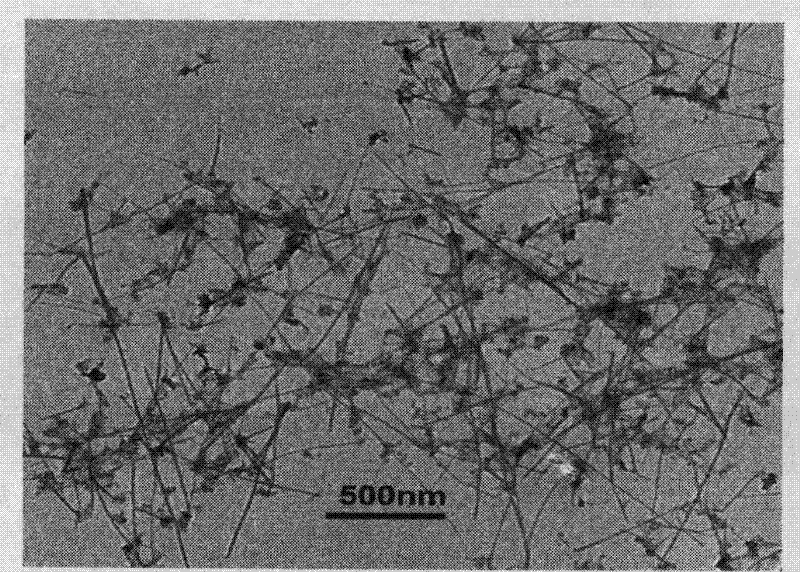

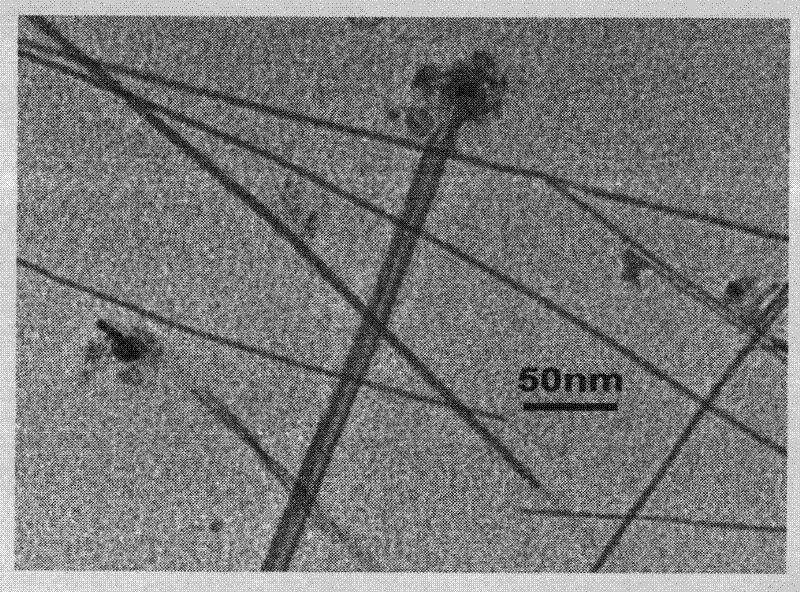

[0019] Put 0.2 g of analytically pure potassium permanganate and 0.5 g of polyvinylpyrrolidone (K30) into a 40 ml polytetrafluoroethylene hydrothermal reaction kettle, add 80% of the reactor volume of deionized water, and stir to form a uniform solution. Seal the reaction kettle and react at 150°C for 10 hours. Then cool to room temperature, open the reaction kettle, vacuum filter, wash with deionized water and absolute ethanol, and dry to obtain a brown powder. The product is identified as manganese oxyhydroxide through X-ray powder diffraction, and the powder X-ray diffraction results are as follows: figure 1 As shown, the material morphology is obtained by transmission electron microscopy results, such as figure 2 , as shown in 3, the diameter distribution of the manganese oxyhydroxide ultrafine nanowires thus obtained is between 4-10 nm, and the length is between 200 nm and 5 μm.

Embodiment 2

[0021] Put 0.2 gram of analytically pure potassium permanganate and 0.1 gram of polyvinylpyrrolidone (K50) in a 40 ml polytetrafluoroethylene hydrothermal reaction kettle, add 80% of reactor volume deionized water, and stir to form a uniform solution. Seal the reaction kettle and react at 120°C for 30 hours. Then cool to room temperature, open the reaction kettle, vacuum filter, wash with deionized water and absolute ethanol, and dry to obtain a brown powder. The obtained product is identified by X-ray powder diffraction and transmission electron microscopy, and is manganese oxyhydroxide ultrafine nanowire.

Embodiment 3

[0023] Put 0.2 g of analytically pure potassium permanganate and 0.7 g of polyvinylpyrrolidone (K50) into a 40 ml polytetrafluoroethylene hydrothermal reaction kettle, add 80% of the reactor volume deionized water, and stir to form a uniform solution. Seal the reaction vessel and react at 170°C for 5 hours. Then cool to room temperature, open the reaction kettle, vacuum filter, wash with deionized water and absolute ethanol, and dry to obtain a brown powder. The obtained product is identified by X-ray powder diffraction and transmission electron microscopy, and is manganese oxyhydroxide ultrafine nanowire.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com