Electrolyte for power lithium ion battery

A lithium-ion battery and electrolyte technology, applied in the field of electrolyte, can solve the problems of low affinity, high contact resistance, and poor pourability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

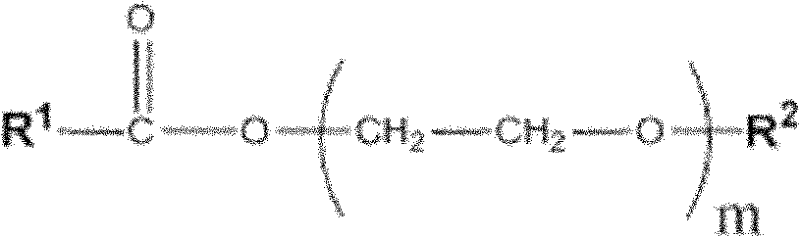

[0038] Electrolyte preparation: In an Ar atmosphere glove box, EC (ethylene carbonate), EMC (ethyl methyl carbonate) and GBL (γ-butyrolactone) were mixed in a mass ratio of 30:40:30, and electromagnetic Stir and add LiPF 6 The electrolyte is configured as an electrolyte solution with a concentration of 1M; and 0.001w.t.% of fatty acid polyoxyethylene ether surfactant C is added thereto 11 h 23 COO(CH 2 CH 2 O) 9 CH 3 , 2w.t.% of VC (vinylene carbonate), 2w.t.% of 1,3-PS (1,3 propane sultone).

[0039] Preparation of cathode material as LiFePO 4 , the negative electrode material is a 22650-type cylindrical battery cell of artificial graphite, and the electrolyte prepared by the above method is used to inject liquid into the cell to assemble a lithium-ion secondary battery.

Embodiment 2

[0041] In an Ar atmosphere glove box, EC (ethylene carbonate), EMC (ethyl methyl carbonate), DMC (dimethyl carbonate) and DEC (diethyl carbonate) were mixed in a mass ratio of 25:45:15:15 , and carry out electromagnetic stirring, add LiPF 6 The electrolyte is configured as an electrolyte solution with a concentration of 1M; and 0.1w.t.% fatty acid polyoxyethylene ether surfactant C is added thereto 11 h 23 COO(CH 2 CH 2 O) 9 CH 3 , 2w.t.% of VC (vinylene carbonate), 2w.t.% of 1,3-PS (1,3 propane sultone).

Embodiment 3

[0043] Repeat Example 1, the difference is to add 0.01w.t.% of C 11 h 23 COO(CH 2 CH 2 O) 9 CH 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com