Cellulose composite microsphere and preparation method thereof

A technology of composite microspheres and cellulose, applied in the field of polymer chemistry, to achieve the effects of short time consumption, large adsorption capacity and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0019] The preparation process of the above-mentioned cellulose composite microspheres can be divided into two steps: the preparation of the cellulose / composite material solution and the preparation of the cellulose composite microspheres.

[0020] Preparation of cellulose / composite material solution: Prepare an aqueous solution of alkali and urea or an aqueous solution of alkali and thiourea, freeze to -12°C to -5°C, then add cellulose and composite material, stir to dissolve, and centrifuge to defoam and remove mixed to obtain a cellulose composite solution.

[0021] Preparation of cellulose composite microspheres: disperse the cellulose composite solution in an emulsifier or an organic solvent of a composite emulsifier, stir at 200-1200r / min until the drop is evenly dispersed, and solidify at room temperature for 1-8 hours at the same stirring speed to form , heated to 40-80°C, adding a cross-linking agent to react for 2-8 hours, adding dilute acid until the solution system...

Embodiment 1

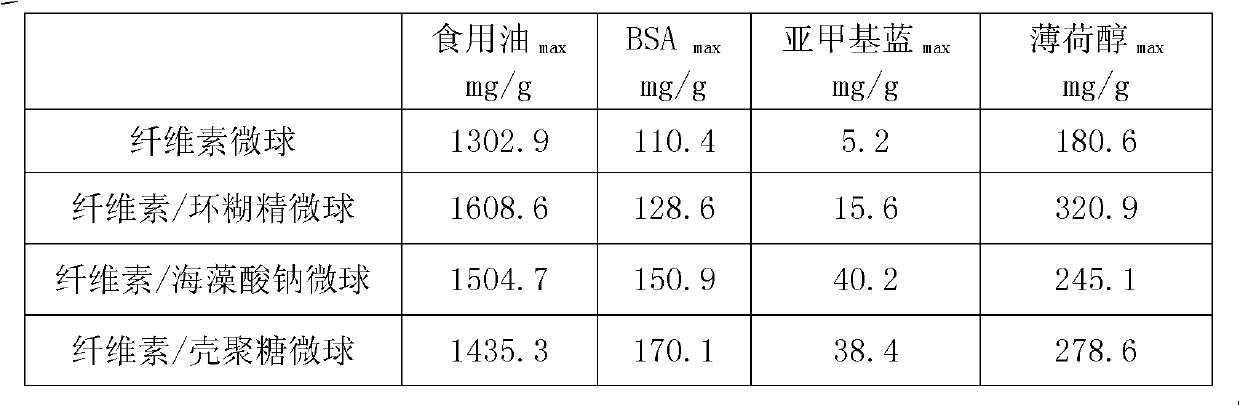

[0024] Prepare 100g of NaOH (5g) / urea (14g) aqueous solution, dissolve and freeze to -12°C, then add 5g of cellulose, stir vigorously to dissolve the cellulose, add 3g of cyclodextrin, stir vigorously to dissolve the cyclodextrin and make the compound solution Disperse evenly. Add 200mL of liquid paraffin and 4g of Span 80 emulsifier into a 500mL three-necked flask equipped with a reflux condenser and a constant temperature water bath, stir at 600r / min to disperse evenly, then slowly add 80mL of the cellulose composite solution prepared by the above method, and Stir for 2 hours, heat to 40° C., add 1 g of glutaraldehyde, react for 2 hours, add 10% hydrochloric acid until the solution is acidic (pH2 / g.

Embodiment 2

[0026]Prepare 100g LiOH (8g) / urea (16g) aqueous solution, dissolve and freeze to -10°C, then add 5g of cellulose, stir vigorously to dissolve the cellulose, add 1g of chitosan, stir vigorously to dissolve chitosan and make the composite solution Disperse evenly. In a 500mL three-necked flask equipped with a reflux condenser and a constant temperature water bath, add 300mL of a mixed solvent of n-hexane and liquid paraffin (volume ratio of 1 / 1), and 4g of Span 60 and 6g of Span 85 mixed emulsifiers, 700r / min After stirring to disperse evenly, slowly add 50 mL of the cellulose composite solution prepared by the above method, stir for 3 hours, heat to 50°C, add 1.5 g of ethylene glycol diglycidyl ether, and continue the reaction for 3 hours, then add 10% hydrochloric acid to The solution is acidic (pH2 / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com