Terpolymer dispersing agent, and preparation method and application thereof

A terpolymer and dispersant technology, applied in maleic anhydride and styrene copolymer dispersants and its preparation, carboxylate copolymers, and photoinitiated methacrylic acid fields, which can solve the problem of weak adsorption and re-agglomeration of solid particles Or precipitation, no problems, etc., to achieve the effect of low total activation energy, pure product and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] 1. Preparation of dispersant:

[0030] Methacrylic acid, maleic anhydride and styrene are 50 parts, 10 parts and 40 parts respectively; Sodium lauryl sulfate and polyethylene glycol octyl phenyl ether are surfactants with a weight ratio of 5:1. 4% of the monomer; thiourea is an anti-crosslinking agent, and the dosage is 4% of the monomer; the photoinitiator dosage is 4% of the monomer; use ethanol as a solvent to make a solution for subsequent use, and the solvent dosage is equal to the monomer mass . Take 10ml of the solution in the photoreaction tube, put nitrogen into the photoreaction tube to discharge the air, and cover it; then put the photoreaction tube into a photoreactor at 15°C and irradiate it with a UV lamp for 50 minutes; a light yellow transparent viscous polymer is formed Add triethylamine solution to neutralize 40%; remove the organic solvent to obtain aqueous dispersant, and then spray dry to obtain white powder.

[0031] Wherein the photoinitiator is...

Embodiment 2

[0050] Methacrylic acid, maleic anhydride and styrene are 60 parts, 20 parts and 20 parts respectively; Sodium lauryl sulfate and polyethylene glycol octyl phenyl ether are surfactants with a weight ratio of 4:1. It is 5% of the total amount of monomer; Thiourea is an anti-crosslinking agent, and the consumption is 9% of the monomer; The quality is equal. Take 10ml of the solution in the photoreaction tube, put nitrogen into the photoreaction tube to discharge the air, and cover it; then put the photoreaction tube into a photoreactor at 15°C and irradiate it with a UV lamp for 50 minutes; a light yellow transparent viscous polymer is formed Material dispersant, add sodium hydroxide solution to neutralize 30%. After removing the organic solvent, an aqueous solution is obtained.

[0051] Wherein, the photoinitiator is lanthanum nitrate-anthraquinone complex, and the preparation method is as follows: mix lanthanum nitrate and anthraquinone in a mass ratio of 1:2 and dissolve th...

Embodiment 3

[0055] Methacrylic acid, maleic anhydride and styrene are 40 parts, 30 parts and 30 parts respectively; Sodium lauryl sulfate and polyethylene glycol octyl phenyl ether are surfactants with a weight ratio of 3:1. 9% of the monomer; thiourea is an anti-crosslinking agent, and the dosage is 7% of the monomer; the photoinitiator dosage is 2% of the monomer; acetone is used as a solvent to prepare a solution for later use, and the amount of the solvent is equal to the mass of the monomer . Take 10ml of the solution in the photoreaction tube, pass nitrogen into the photoreaction tube to discharge the air, and cover it; then put the photoreaction tube into a photoreactor at 20°C and irradiate it with a UV lamp for 100 minutes; a light yellow transparent viscous polymer is formed Add ammonia water to neutralize 90% of the substance dispersant; get the water agent after removing the organic solvent.

[0056] Wherein, the photoinitiator is lanthanum nitrate-benzophenone complex, and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

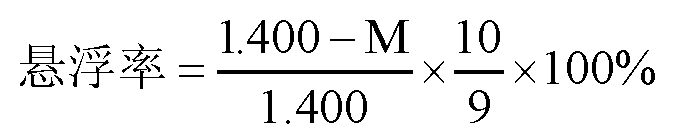

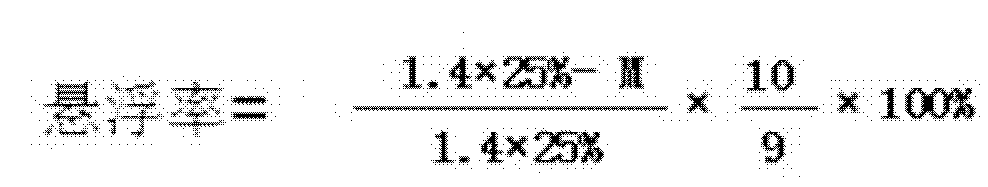

| suspension rate | aaaaa | aaaaa |

| suspension rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com