Oxazine and alkyne compound modified silicon-containing aryne resin and preparing method thereof

A silicon aryne and compound technology, which is applied in the field of modified silicon-containing aryne resin, modified silicon-containing aryne resin and its preparation, can solve the problems of unsatisfactory fiber adhesion, low high temperature resistance, and high resin viscosity. , to achieve excellent mechanical properties and heat resistance, low viscosity of molten resin, and low softening point

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

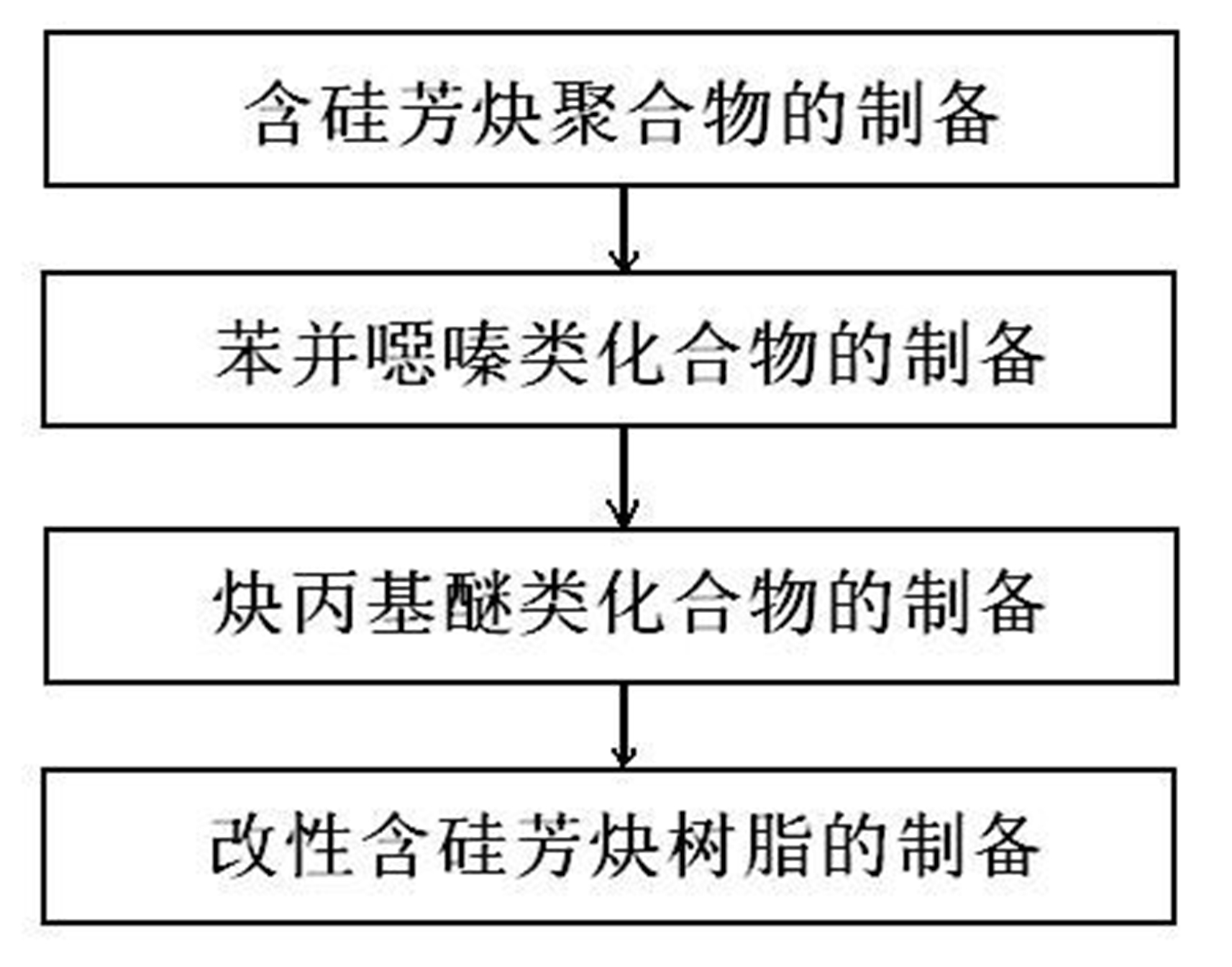

Method used

Image

Examples

Embodiment 1

[0057] The preparation of bisphenol A ethynyl benzoxazine and bisphenol A dipropargyl ether modified dimethyl type silicon-containing aryne resin (BAP-DABPA-PSAM-20) comprises the following steps:

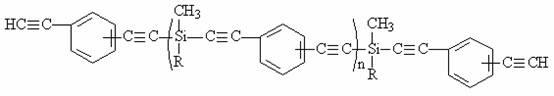

[0058] (1) Preparation of dimethyl-type silicon-containing aryne resin (PSAM)

[0059] Add 6.00g (0.25 mol) of treated magnesium powder and 50mL of tetrahydrofuran (THF) into a 250mL four-neck flask equipped with a stirring, constant pressure funnel and spherical condenser, and then slowly add ethyl bromide dropwise through the constant pressure funnel. A mixed solution of 21.60 g (0.20 mol) of alkane and 50 mL of THF; the dropwise addition was completed within 1.5 hours, and then refluxed for 1.5 hours to obtain a gray-black ethyl Grignard reagent;

[0060] A mixed solution of 11.35 g (0.09 mol) of diethynylbenzene and 50 mL of THF was added dropwise under cooling in an ice-water bath, the reaction mixture gradually changed from gray-black to gray-white, and the dropwise addition ...

Embodiment 2

[0077] The preparation of bisphenol A ethynyl benzoxazine and bisphenol A dipropargyl ether modified dimethyl type silicon-containing aryne resin (BAP-DABPA-PSAM-25) comprises the following steps:

[0078] Steps (1), (2), and (3) are the same as in Example 1.

[0079] (4) Preparation of bisphenol A ethynyl benzoxazine and bisphenol A dipropargyl ether modified dimethyl silicon-containing aryne resin (BAP-DABPA-PSAM-25)

[0080] Add 2.0g (10 parts by weight) of BAP, 3.0g (15 parts by weight) of DABPA, and 15.0g (75 parts by weight) of PSAM into a reactor equipped with a stirrer, a thermometer and a reflux condenser, and pass an inert gas, Slowly raise the temperature to 120°C, start stirring, and continue stirring for 3.0 hours after the reactants are melted and homogeneous, and a reddish-brown viscous resin is obtained.

[0081] The reddish-brown viscous resin has a resin viscosity of less than 0.4 Pa·s in the range of 120-200° C., and at a temperature higher than 200° C., th...

Embodiment 3

[0084]The preparation of bisphenol A ethynyl benzoxazine and bisphenol A dipropargyl ether modified dimethyl silicon-containing aryne resin (BAP-DABPA-PSAM-50) comprises the following steps:

[0085] Steps (1), (2), and (3) are the same as in Example 1.

[0086] (4) Preparation of bisphenol A ethynyl benzoxazine and bisphenol A dipropargyl ether modified dimethyl silicon-containing aryne resin (BAP-DABPA-PSAM-50)

[0087] Add 5.0g (25 parts by weight) of BAP, 5.0g (25 parts by weight) of DABPA, and 10.0g (50 parts by weight) of PSAM into a reactor with a stirrer, a thermometer and a reflux condenser, and pass an inert gas, Slowly raise the temperature to 140°C, start stirring, and continue stirring for 4.0 hours after the reactants are melted and homogeneous, and a reddish-brown viscous resin is obtained.

[0088] The reddish-brown viscous resin has a resin viscosity of less than 0.4 Pa·s in the range of 120-210° C., and at a temperature higher than 210° C., the resin viscosi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com