Preparation method of durable low-smoke halogen-free flame-retardant polyacrylonitrile fiber

A technology of polyacrylonitrile fiber and flame-retardant polyacrylonitrile, which is applied in the manufacture of fire-resistant and flame-retardant filaments, fiber chemical characteristics, single-component synthetic polymer rayon, etc., and can solve migration, polyacrylonitrile fiber moisture absorption, etc. To solve the problem, achieve the effects of small damage to mechanical properties, improve flame retardant performance, solve flame retardant durability and flame retardant migration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

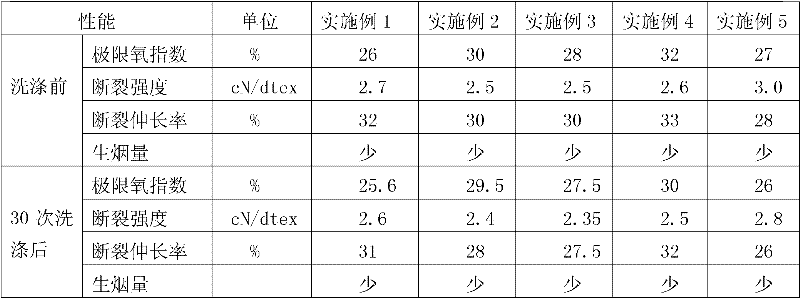

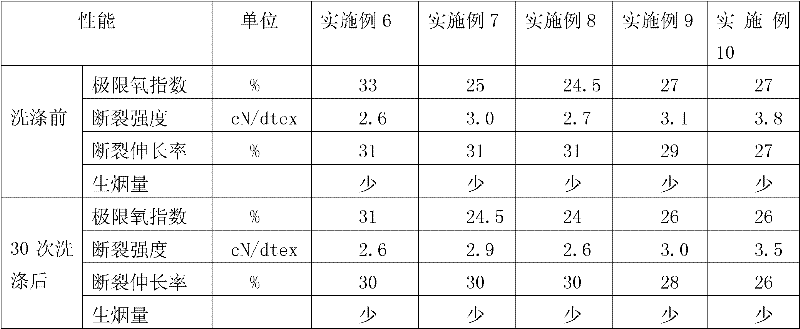

Examples

Embodiment 1

[0027] The preparation method of durable low-smoke halogen-free flame-retardant polyacrylonitrile fiber, it comprises the steps:

[0028] 1) Preparation of blended spinning stock solution: according to the mass fraction of industrial spinning grade polyacrylonitrile powder and phosphorus-containing flame retardant: 80 parts of industrial spinning grade polyacrylonitrile powder, 20 parts of phosphorus-containing flame retardant, Industrial spinning grade polyacrylonitrile powder and phosphorus-containing flame retardant are selected; the phosphorus-containing flame retardant is methyl vinyl phosphonate.

[0029] Described industrial spinning grade polyacrylonitrile powder (copolymer) is the general industrial spinning grade polyacrylonitrile powder that Shanghai Petrochemical Co., Ltd. produces, model PAN 60, and the composition of its powder copolymer is: acrylonitrile monomer 90wt%, vinyl acetate 8wt%, sodium methacrylsulfonate 2wt%.

[0030] According to the mass ratio of t...

Embodiment 2

[0038] The preparation method of durable low-smoke halogen-free flame-retardant polyacrylonitrile fiber, it comprises the steps:

[0039]1) Preparation of blended spinning stock solution: according to the mass fraction of industrial spinning grade polyacrylonitrile powder and phosphorus-containing flame retardant: 70 parts of industrial spinning grade polyacrylonitrile powder, 30 parts of phosphorus-containing flame retardant, Select industrial spinning grade polyacrylonitrile powder and phosphorus-containing flame retardant; the phosphorus-containing flame retardant is methyl vinyl phosphonate.

[0040] Described industrial spinning grade polyacrylonitrile powder (copolymer) is the general industrial spinning grade polyacrylonitrile powder that Shanghai Petrochemical Co., Ltd. produces, model PAN 60, and the composition of its powder copolymer is: acrylonitrile monomer 90wt%, vinyl acetate 8wt%, sodium methacrylsulfonate 2wt%.

[0041] According to the mass ratio of the tota...

Embodiment 3

[0047] The preparation method of durable low-smoke halogen-free flame-retardant polyacrylonitrile fiber, it comprises the steps:

[0048] 1) Preparation of blended spinning stock solution: according to the mass fraction of industrial spinning grade polyacrylonitrile powder and phosphorus-containing flame retardant: 75 parts of industrial spinning grade polyacrylonitrile powder, 25 parts of phosphorus-containing flame retardant, Select industrial spinning grade polyacrylonitrile powder and phosphorus-containing flame retardant; the phosphorus-containing flame retardant is allyl ethyl phosphate.

[0049] Described industrial spinning grade polyacrylonitrile powder (copolymer) is the general industrial spinning grade polyacrylonitrile powder that Shanghai Petrochemical Co., Ltd. produces, model PAN 60, and the composition of its powder copolymer is: acrylonitrile monomer 90wt%, vinyl acetate 8wt%, sodium methacrylsulfonate 2wt%.

[0050] According to the mass ratio of the polyac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com