Low-histamine fish product processing method

A processing method and fish meat technology, applied in the field of processing low-histamine fish meat products, can solve problems such as poisoning, histamine poisoning (allergic food poisoning), histamine poisoning of eaters, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

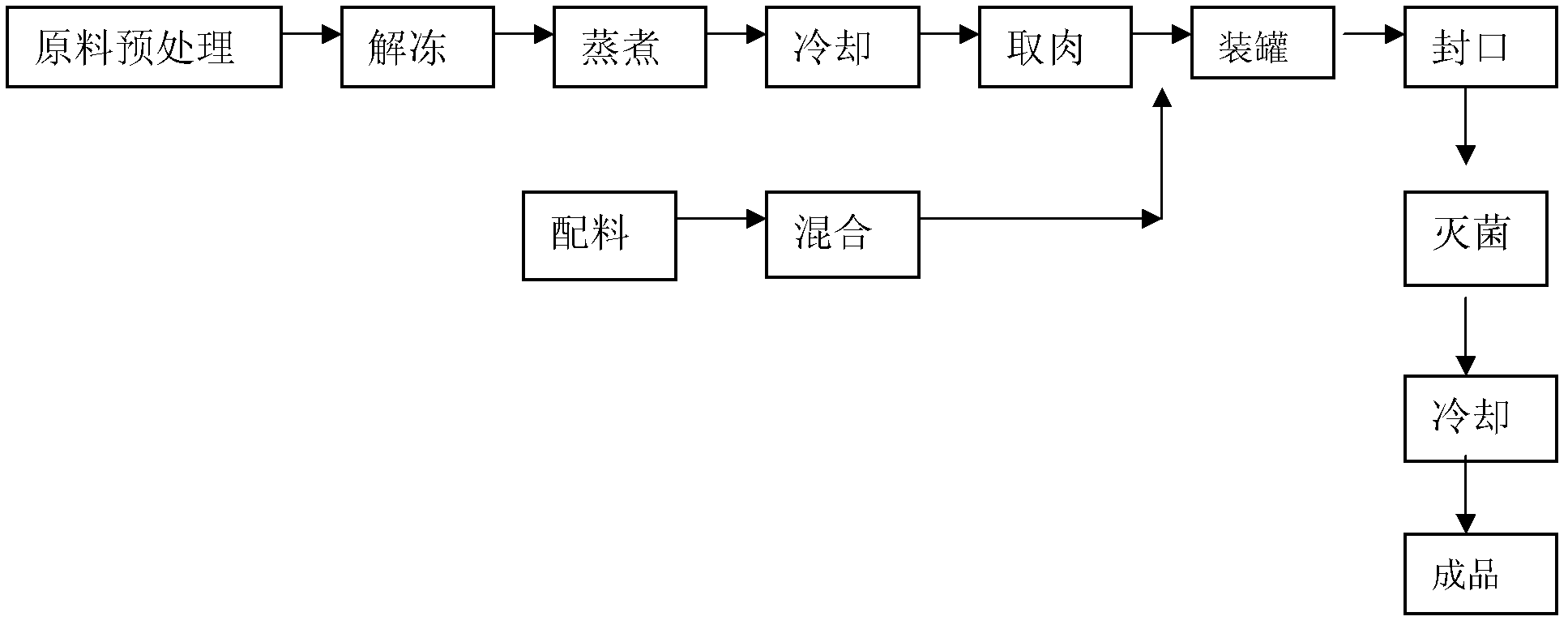

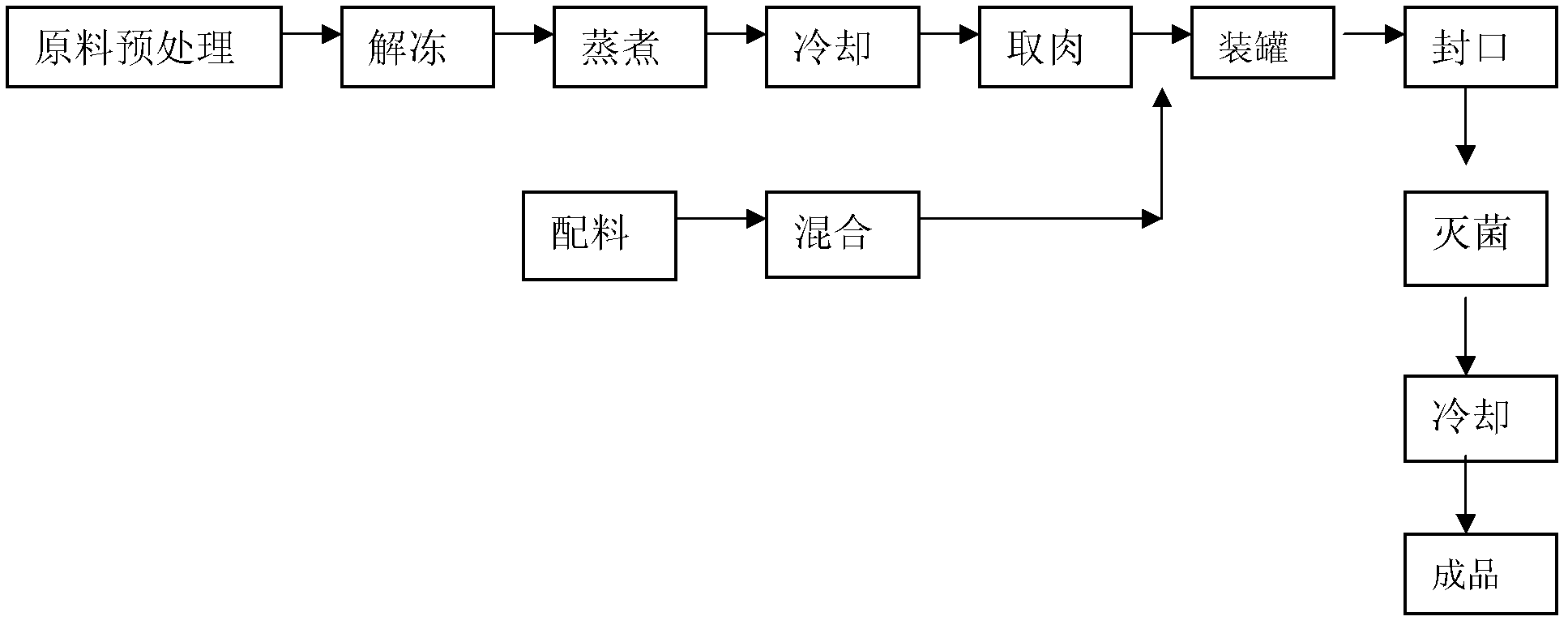

[0022] A kind of processing method of low-histamine fish meat product of the present invention, such as figure 1 As shown, the specific steps are as follows:

[0023] (1) Sorting pretreatment: remove some incomplete or even rotten raw fish from the raw fish kept fresh on ice before being transported into the freezer;

[0024] (2) To control the temperature during the thawing process of the raw fish, use flowing water with a moderate flow rate for thawing, the water temperature in the thawing tank shall not exceed 15°C, and the processing time shall not exceed 45 minutes;

[0025] (3) Control of ambient temperature and air humidity in processing operations: control the indoor ambient temperature of the batching and canning processing workshop below 21°C, and control the relative humidity of the indoor air below 70%;

[0026] (4) The control and operation method of the ingredients in the processing process: the raw fish processed by the steam heating sterilizer is rapidly coole...

Embodiment 2

[0032] Same as Example 1, the difference is: the indoor ambient temperature of the processing workshop for batching and canning is controlled at 16° C., and the relative humidity of the indoor air is controlled at 40%. The steam sterilizer uses atmospheric pressure steam to treat the fish body to a central temperature of 75°C, and the treatment time is controlled at 30 minutes.

Embodiment 3

[0034] Same as Example 1, the difference is: the indoor ambient temperature of the processing workshop for batching and canning is controlled at 20°C, and the relative humidity of the indoor air is controlled at 70%. The steam sterilizer uses atmospheric pressure steam to treat the fish body center temperature to 80°C, and the treatment time is controlled at 20 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com