Nanometer zinc oxide-bismuth oxide composite photocatalyst with visible light response and preparation method thereof

A technology of nano-zinc oxide and photocatalyst, which is applied in the direction of metal/metal oxide/metal hydroxide catalyst, physical/chemical process catalyst, chemical instrument and method, etc., to improve catalytic performance, improve adsorption performance, and improve photocatalysis active effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Implementation Example 1: The preparation method of the nanometer zinc oxide-bismuth oxide composite photocatalyst of visible light response of the present invention comprises the following steps:

[0020] Stir and dissolve zinc nitrate, bismuth nitrate and urea in water respectively, the mol ratio of zinc nitrate, bismuth nitrate and urea is 1: 0.02: 1.10, the mixed solution carries out co-precipitation reaction, the reaction temperature is 90 ℃, and the reaction time is 8 hours, The obtained product was separated by centrifugation, washed with deionized water, dried at 60° C. for 12 hours, and calcined at 300° C. for 3 hours to obtain a nanometer zinc oxide-bismuth oxide composite.

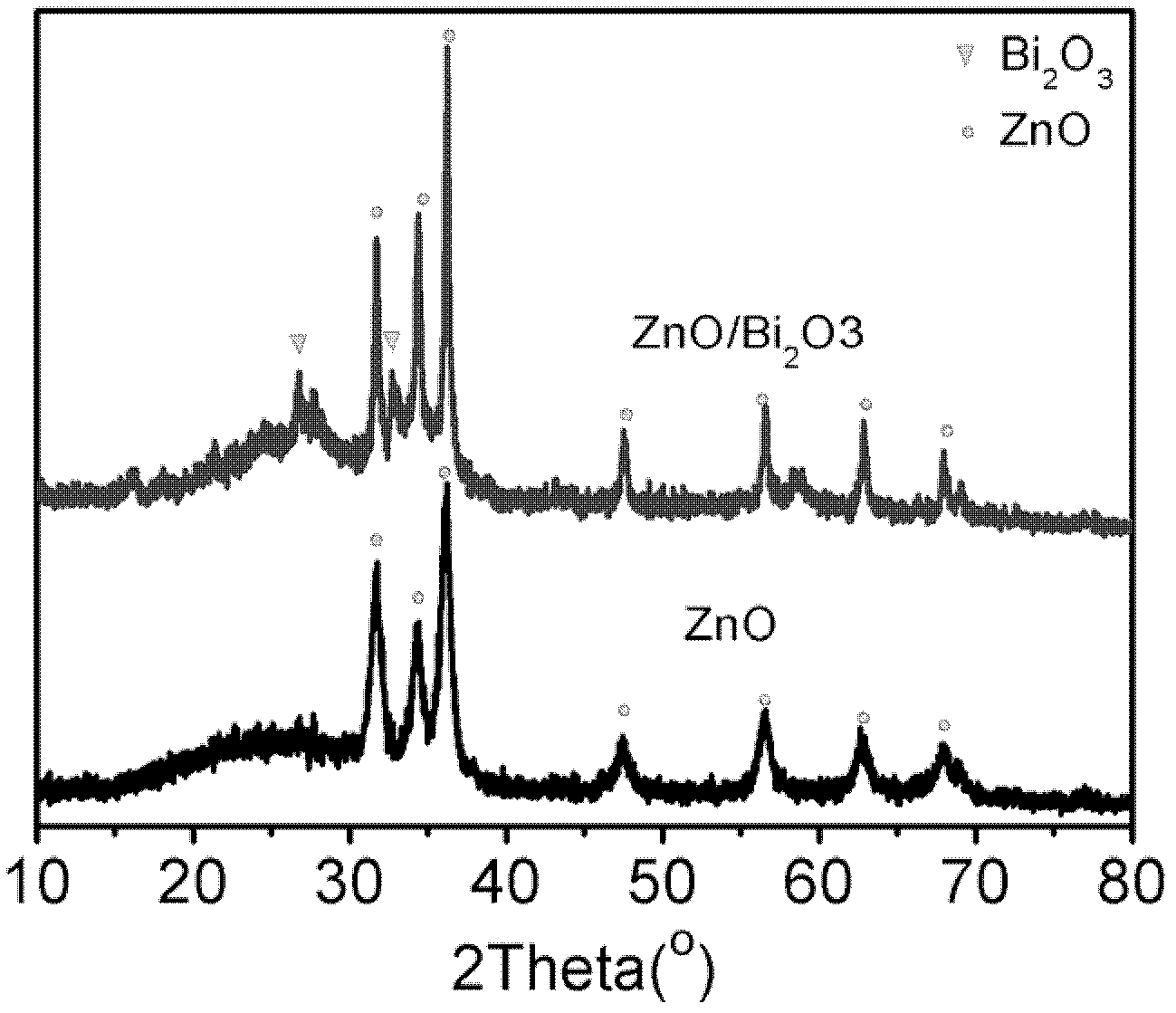

[0021] Characterized by X-ray diffraction (XRD), the obtained product is wurtzite zinc oxide (JCPDS, 36-1451), compared with nano-zinc oxide, the characteristic peak of zinc oxide in nano-zinc oxide-bismuth oxide composite sharper, indicating that the addition of bismuth oxide increases t...

Embodiment 2

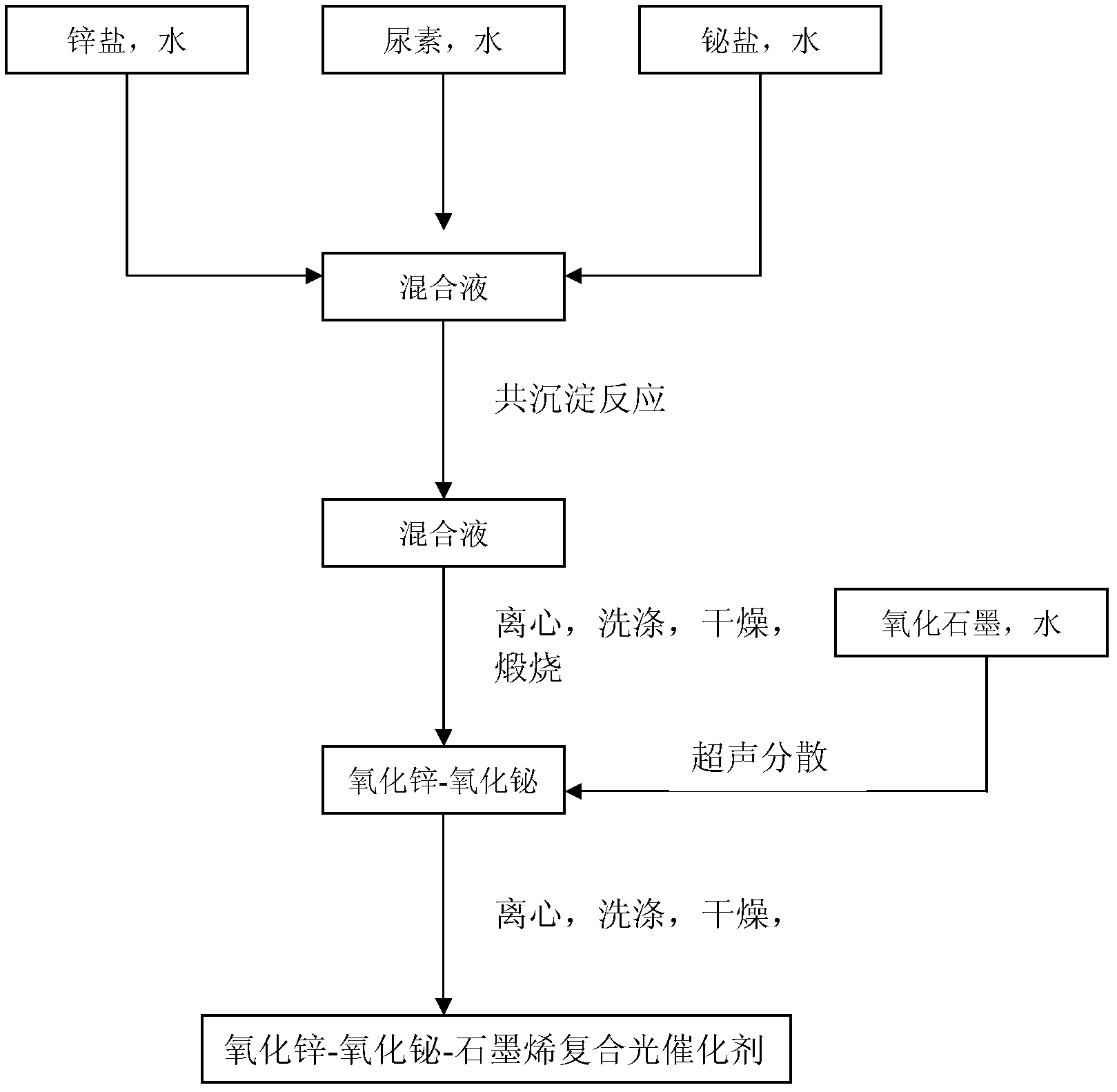

[0022] Implementation example 2: The preparation method of the nanometer zinc oxide-bismuth oxide-graphene oxide composite photocatalyst of visible light response of the present invention, comprises the following steps:

[0023] The first step is the preparation of graphite oxide. Graphite oxide is prepared by oxidizing graphite with strong oxidizing agents such as nitric acid and sulfuric acid.

[0024] In the second step, 50 mg of graphite oxide was ultrasonically dispersed in 100 mL of deionized water for 2 hours to prepare a graphene oxide dispersion.

[0025] In the third step, water-soluble zinc chloride, bismuth nitrate and urea are stirred and dissolved in water respectively, the molar ratio of zinc chloride, bismuth nitrate and urea is 1: 0.02: 1.10, and the mixed solution carries out co-precipitation reaction, and the reaction temperature is 90 °C, the reaction time is 8 hours, the obtained product is centrifuged, washed with deionized water, dried at 60 °C for 12 h...

Embodiment 3

[0027] Implementation example 3: The preparation method of the nanometer zinc oxide-bismuth oxide-graphene oxide composite photocatalyst of visible light response of the present invention, comprises the following steps:

[0028] The first step is the same as Step 1 in Implementation Example 2.

[0029] In the second step, 100 mg of graphite oxide was ultrasonically dispersed in 100 mL of deionized water for 2 hours to prepare a graphene oxide dispersion.

[0030] The third step is to stir and dissolve zinc sulfate, bismuth nitrate and urea in water respectively. The molar ratio of zinc sulfate, bismuth nitrate and urea is 1:0.10:1.10, and the mixed solution is subjected to coprecipitation reaction. The reaction temperature is 93°C, and the reaction time is After 9 hours, the obtained product was centrifuged, washed with deionized water, dried at 60° C. for 12 hours, and calcined at 500° C. for 3 hours to obtain a nano-zinc oxide-bismuth oxide composite.

[0031] The fourth st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com