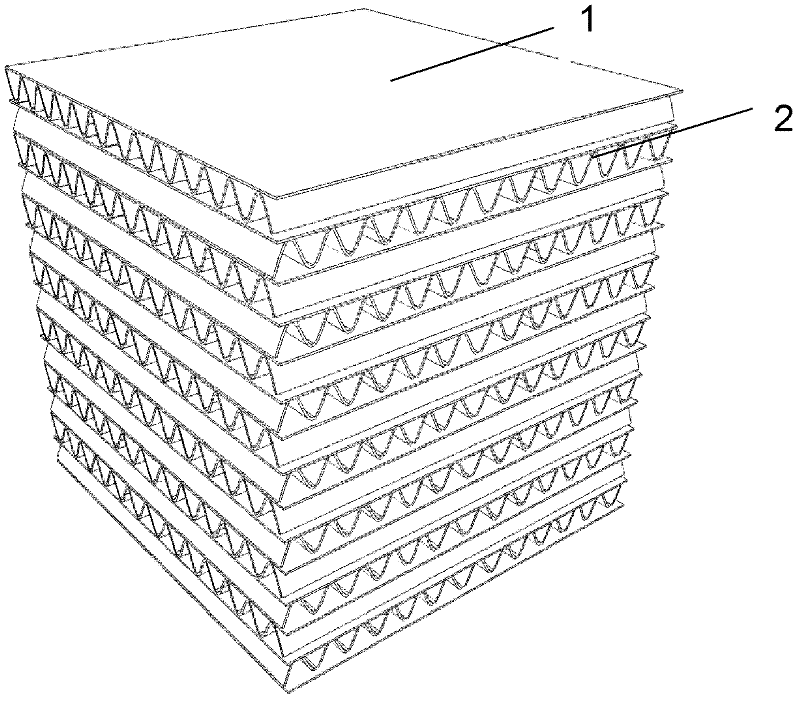

Preparation method of high heat conductive and hight temperature resistant corrugated ceramic-based heat exchanger chip

A ceramic base and heat exchanger technology, applied in ceramic products, other household appliances, household appliances, etc., to achieve the effects of enhancing strength, reducing contact thermal resistance, and high heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Quantitatively 100g / m 2 The ceramic fiber paper (200mm wide, 0.5mm thick cylindrical roll paper, containing 3% polyvinyl alcohol fiber) is immersed in the glue solution (containing 6% polyvinyl alcohol) with a mass concentration of 30% of silica sol for 30s until completely Soaked and formed by corrugating rollers at 120°C to obtain corrugated surface paper; flat bottom paper, basis weight: 30g / m 2 Ceramic fiber paper (200mm wide, 0.15mm thick cylindrical roll paper, containing 3% by mass polyvinyl alcohol fiber) is bonded to the corrugated surface after being impregnated in the same concentration of silica sol (containing 6% polyvinyl alcohol) On the paper, a corrugated ceramic-based double-sided fiber paper is formed. It should be noted that the corrugated surface paper is relatively thick based on the formation of better single-sided corrugated paper, while the backing paper should be as thin as possible. On the one hand, it can increase the specific surface area of...

Embodiment 2

[0035] Quantitatively 100g / m 2 The ceramic fiber paper (200mm wide, 0.5mm thick cylindrical roll paper, containing 5% wood pulp fiber) was soaked in the glue solution (containing 8% vinyl acetate glue) with a mass concentration of water glass of 30% for 30s and waited to be completely soaked. Corrugated roll 120 ℃ heat forming corrugated face paper, flat bottom paper (weight: 30g / m 2 Ceramic fiber paper, 200mm wide, 0.15mm thick cylindrical roll paper) is impregnated in the same concentration of water glass (containing 5% vinyl acetate glue), and then bonded to corrugated paper to form a corrugated ceramic-based double-sided fiber paper . Using sodium silicate inorganic glue with 3% copper oxide powder as the binder, cut the double-sided corrugated paper into 20×20 squares, stack them alternately at 90° angles along the corrugated paper channels along the square surface, and form a honeycomb shape after bonding Cube (20cm×20cm×20cm), first slowly solidified and bonded (4hr) ...

Embodiment 3

[0038] Quantitatively 100g / m 2 The ceramic fiber paper (200mm wide, 0.5mm thick cylindrical roll paper, containing 5% polyamide fiber) was immersed in the glue solution (containing 5% vinyl acetate glue) with a mass concentration of silica sol of 30% for 30s until completely soaked, and then Corrugated roll 120 ℃ heat forming corrugated face paper, flat bottom paper (weight: 30g / m 2 Ceramic fiber paper, 200mm wide, 0.15mm thick cylindrical roll paper) is impregnated in the same concentration of silica sol, and then bonded to corrugated paper to form a corrugated ceramic-based double-sided fiber paper. Using sodium silicate inorganic glue with 3% copper oxide powder as the binder, cut the double-sided corrugated paper into 20×20 squares, stack them alternately at 90° angles along the corrugated paper channels along the square surface, and form a honeycomb shape after bonding Cube (20cm×20cm×20cm), first slowly solidified and bonded (4hr) in a 90°C blast oven, after cooling, tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com