Synthetic method of 7-(4-ethyl-1-methyl octyl)-8-hydroxyquinoline

A technology of hydroxyquinoline and methyl octyl, which is applied in the field of synthesis of 7--8-hydroxyquinoline, can solve the problems of lower product yield, low single-pass conversion rate, condensation by-products, etc., and achieve good quality and high yield. high rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

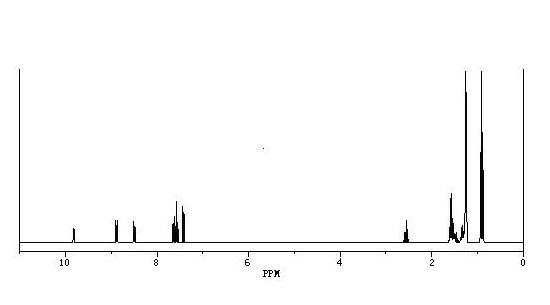

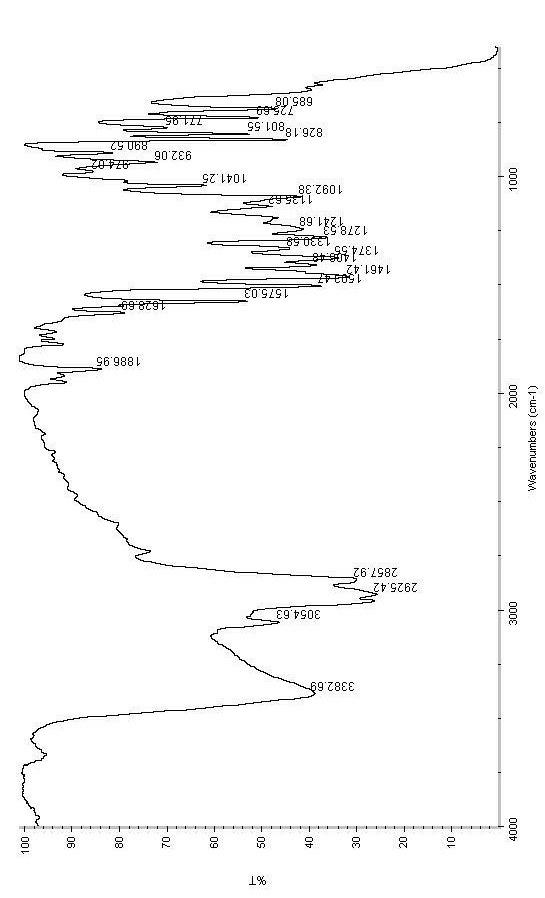

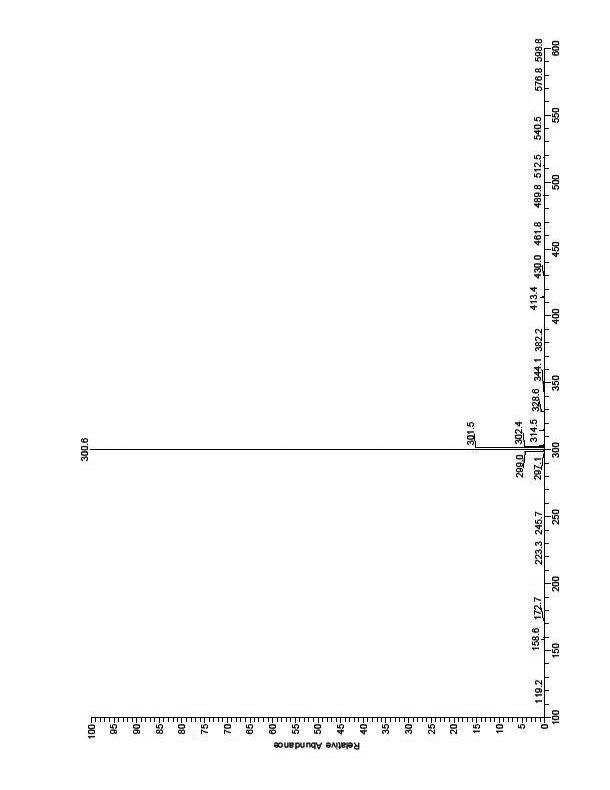

Image

Examples

Embodiment 1

[0037] Embodiment 1, a kind of synthetic method of 7-(4-ethyl-1-methyloctyl)-8-hydroxyquinoline, its steps are as follows:

[0038] (1) In a solvent, under alkali catalysis, 8-hydroxyquinoline and halogenated alkenes undergo a Williamson synthesis reaction to generate 8-[4-(5-ethyl-2-nonene)]oxyquinoline, and the reaction The temperature is 30°C, phenyl allyl ether undergoes Claisen rearrangement at this reaction temperature, and phenyl allyl ether undergoes intramolecular rearrangement to generate o-allyl 8-hydroxyquinoline, that is, to generate 7-alkenyl -8-hydroxyquinoline, which also generates 7-(4-ethyl-1-methyloctenyl)-8-hydroxyquinoline; the reaction time is 0.5 hours;

[0039] The molar ratio of the raw material halogenated olefin, 8-hydroxyquinoline and solvent is 1:0.5:2;

[0040]The halogenated olefin is 3-chloro-5-ethyl-2-nonene;

[0041] The solvent is N,N-dimethylformamide;

[0042] The catalyst base is selected from sodium hydroxide, potassium hydroxide, pota...

Embodiment 2

[0044] Embodiment 2, a kind of synthetic method of 7-(4-ethyl-1-methyloctyl)-8-hydroxyquinoline, its steps are as follows:

[0045] (1) In a solvent, under alkali catalysis, 8-hydroxyquinoline and halogenated alkenes undergo a Williamson synthesis reaction to generate 8-[4-(5-ethyl-2-nonene)]oxyquinoline, and the reaction The temperature is 180°C, phenyl allyl ether undergoes Claisen rearrangement at this reaction temperature, and phenyl allyl ether undergoes intramolecular rearrangement to generate o-allyl 8-hydroxyquinoline, that is, to generate 7-alkenyl -8-hydroxyquinoline, which also generates 7-(4-ethyl-1-methyloctenyl)-8-hydroxyquinoline; the reaction time is 12 hours;

[0046] The molar ratio of raw material halogenated olefin, 8-hydroxyquinoline and solvent is 1: 6: 12;

[0047] The halogenated olefin is 3-bromo-5-ethyl-2-nonene or 3-iodo-5-ethyl-2-nonene;

[0048] Described solvent is methanol or benzene;

[0049] The catalyst base is made by mixing an inorganic b...

Embodiment 3

[0051] Embodiment 3, a kind of synthetic method of 7-(4-ethyl-1-methyloctyl)-8-hydroxyquinoline, its steps are as follows:

[0052] (1) In a solvent, under alkali catalysis, 8-hydroxyquinoline and halogenated alkenes undergo a Williamson synthesis reaction to generate 8-[4-(5-ethyl-2-nonene)]oxyquinoline, and the reaction The temperature is 100°C, phenyl allyl ether undergoes Claisen rearrangement at this reaction temperature, and phenyl allyl ether undergoes intramolecular rearrangement to generate o-allyl 8-hydroxyquinoline, that is, to generate 7-alkenyl -8-hydroxyquinoline, which also generates 7-(4-ethyl-1-methyloctenyl)-8-hydroxyquinoline; the reaction time is 6 hours;

[0053] The molar ratio of raw material halogenated olefin, 8-hydroxyquinoline and solvent is 1:3:7;

[0054] The halogenated olefin is 3-iodo-5-ethyl-2-nonene;

[0055] Described solvent is toluene or cyclohexane;

[0056] The catalyst base is made by mixing an inorganic base with a low-carbon monohyd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com