Betaine type salt-resistant polymer and preparation method thereof

A technology of polymer and betaine, applied in drilling compositions, chemical instruments and methods, etc., can solve the problems of inability to meet market demand and limited product types, and achieve easy industrial production, convenient operation and mild reaction conditions. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The synthesis of embodiment 1 betaine type salt-resistant polymer

[0034] (1) Synthesis of Acryloyl Chloride

[0035] Put a 150ml single-mouth round bottom flask into an oil bath, add 57g of acrylic acid, 140g of benzoyl chloride and a small amount of hydroquinone polymerization inhibitor, condense and reflux at 80°C for 3h under uniform stirring, and distill under reduced pressure with a diaphragm vacuum pump for 0.5h. Add a small amount of hydroquinone to the collection bottle and place it in a water bath at 3±0.1°C. 16.5 g of acryloyl chloride was obtained as a colorless and transparent liquid product.

[0036] (2) Synthesis of propylene diamine quaternary ammonium salt

[0037] Dissolve 12g of chloroacetic acid in 20g of pure water, add 7.4g of anhydrous sodium carbonate to pH6.5-7, and filter to remove a small amount of insoluble sodium carbonate. The filtrate was poured into a 150ml single-necked flask, and 10g of N,N-dimethyl-1,3-propanediamine was slowly add...

Embodiment 2

[0042] The structural characterization of embodiment 2 acrylamidopropyl betaine

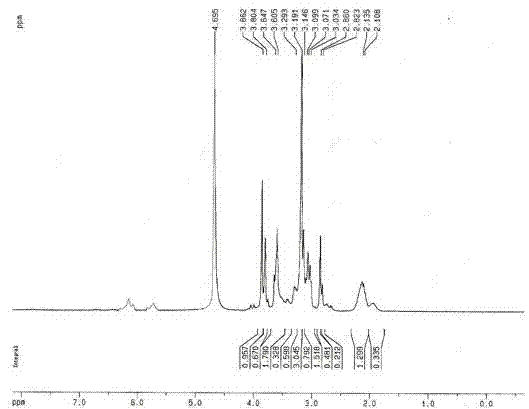

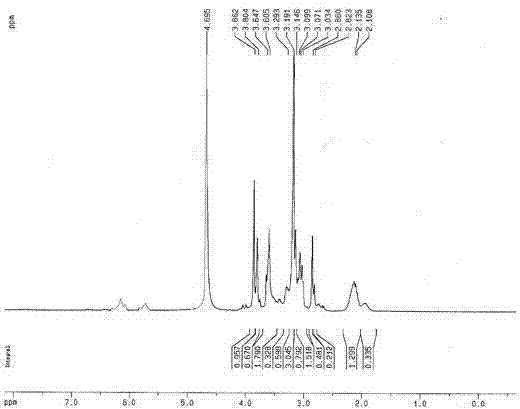

[0043] figure 1 It is the proton nuclear magnetic resonance spectrogram of the acrylamidopropyl betaine prepared in embodiment 1, and the proton displacement δ is: methyl (3.293), methylene (1.860 to 2.860) in the propylenediamine group, acrylamide group The N-H bond in (2.823), the CH2=CH double bond in the acrylamide group (around 5.7 and 6.3), the methylene group in the chloroacetic acid group (3.071).

[0044] It can be seen from the analysis of the spectrogram data that the product is acrylamidopropyl betaine.

Embodiment 3

[0045] The structural characterization of embodiment 3 polymer

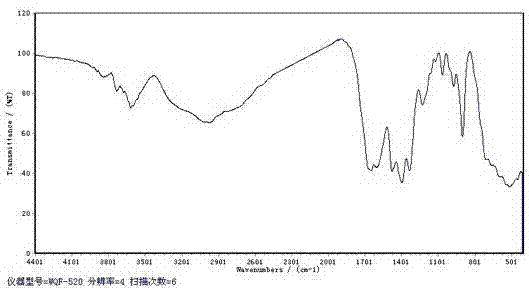

[0046] figure 2 It is the copolymer infrared spectrogram of the acrylamidopropyl betaine / acrylamide / N-alkylacrylamide prepared in Example 1, and it is known by the analysis of the spectrogram: 1734cm -1 Is the C=O vibration peak; 1600cm -1 Is amide (secondary amine) vibration characteristic peak; 3575cm -1 Is the N-H vibration peak; 1398cm -1 Is the methyl vibration peak; 1481cm -1 Is the methylene vibration peak; 1670cm -1 Is the characteristic peak of quaternary ammonium N; 1123cm -1 is the C-N vibration peak of aliphatic amines.

[0047] Various functional groups of the polymer were analyzed by infrared spectroscopy, and the results showed that the synthesized polymer had the characteristics of acrylamidopropyl betaine / acrylamide / N-alkylacrylamide copolymer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com