Preparation method of iron-coated graphene nanocomposite material

A nanocomposite material and graphene technology, which is applied in the field of preparation of iron-coated graphene nanocomposite materials, can solve the problems of inability to realize carbon nanomaterial/metal interface transfer, difficult to achieve performance enhancement, serious agglomeration, etc., and achieve product realization. Function refinement, preparation method and effects of simple materials and low preparation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

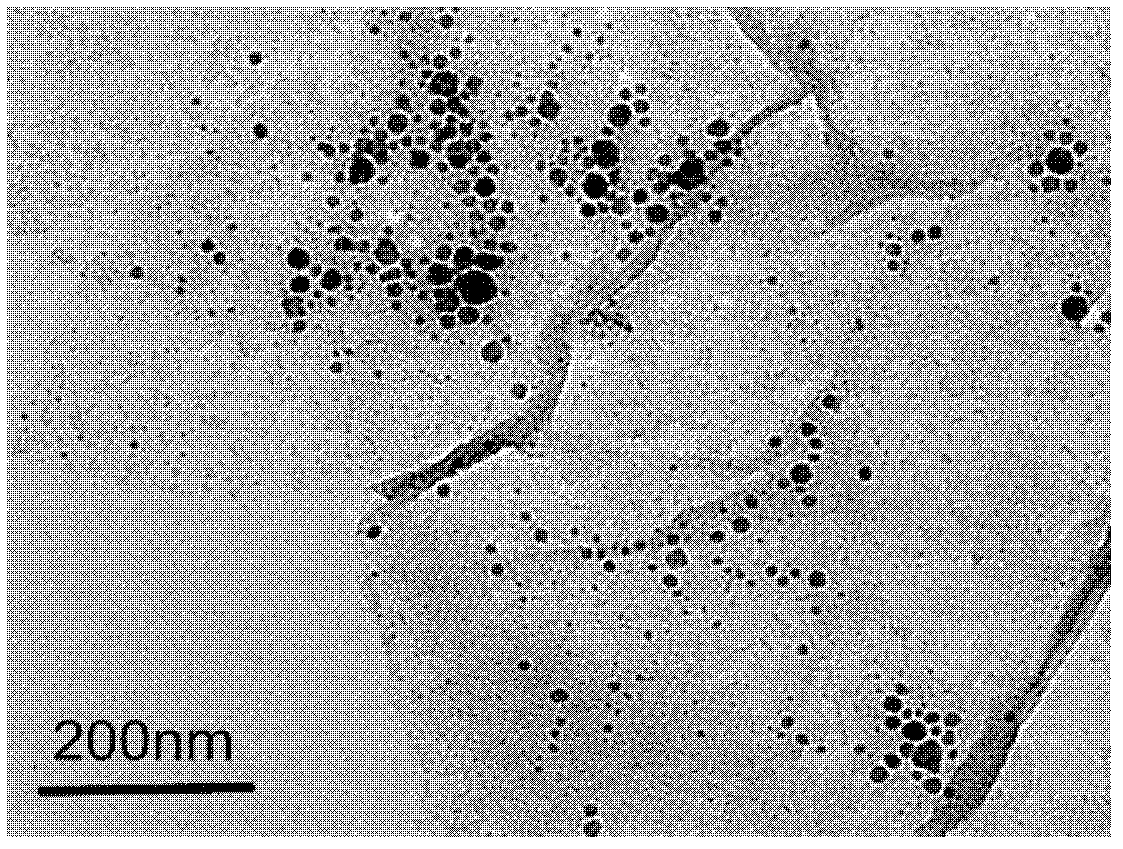

Embodiment 1

[0028] Take 20 mg of graphite oxide and put it in a crucible, wrap it with tin foil paper, push it into a tube furnace at 300°C (500°C or 600°C, the time is shorter) for 3min thermal expansion treatment, and the obtained multilayer graphite Add 100 mg of alkene and 500 ml of kerosene into a four-necked flask, and the four-necked flask is respectively connected with a condenser, a temperature controller, a mechanical stirrer, and an air inlet pipe. Nitrogen was introduced for 10 minutes to remove the air, and under the condition of stirring speed of 180r / min, the kerosene solution was slowly heated to 220°C with an electric heating mantle for condensation and reflux. Use N 2 As a guide gas, lead carbonyl iron vapor into kerosene (gasoline or isopropanol) solution for decomposition, N 2 The flow rate was 120ml / min, and the reaction lasted 180min. in N 2 The temperature was gradually lowered and cooled under protection, and the sample was magnetically separated, washed three t...

Embodiment 2

[0035] Take 20 mg of graphite oxide and put it in a crucible, wrap it with tinfoil, push it into a tube furnace at 500 ° C for 5 minutes of thermal expansion treatment, and obtain multilayer graphene. Add 100 mg of multilayer graphene and 500 ml of kerosene into a four-necked flask, The four-necked flask was connected with a condenser, a temperature controller, a mechanical stirrer, and an inlet pipe respectively. Nitrogen (N 2 ) for 10 minutes, and under the condition of a stirring speed of 180r / min, use an electric heating mantle to slowly heat the kerosene solution to 240°C for condensation and reflux. Use N 2 As a guide gas, lead iron pentacarbonyl vapor into the kerosene solution for decomposition, N 2 The flow rate was 120ml / min, and the reaction lasted 360min. in N 2 Gradually cool down under protection. The sample was magnetically separated, washed three times with n-octane, acetone, and absolute ethanol in sequence, and dried at 60 °C under nitrogen protection. T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com