Method for preparing nitrogen-doped nanometer TiO2 fiber cloth

A nitrogen-doped, fiber cloth technology is applied in the field of nano-TiO2 functional fiber material preparation, which can solve the problems of inability to efficiently and stably exert photocatalytic performance, low resistance to water impact load, poor mechanical strength, etc., and achieve easy recycling and reuse. , The effect of strong resistance to water impact load and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

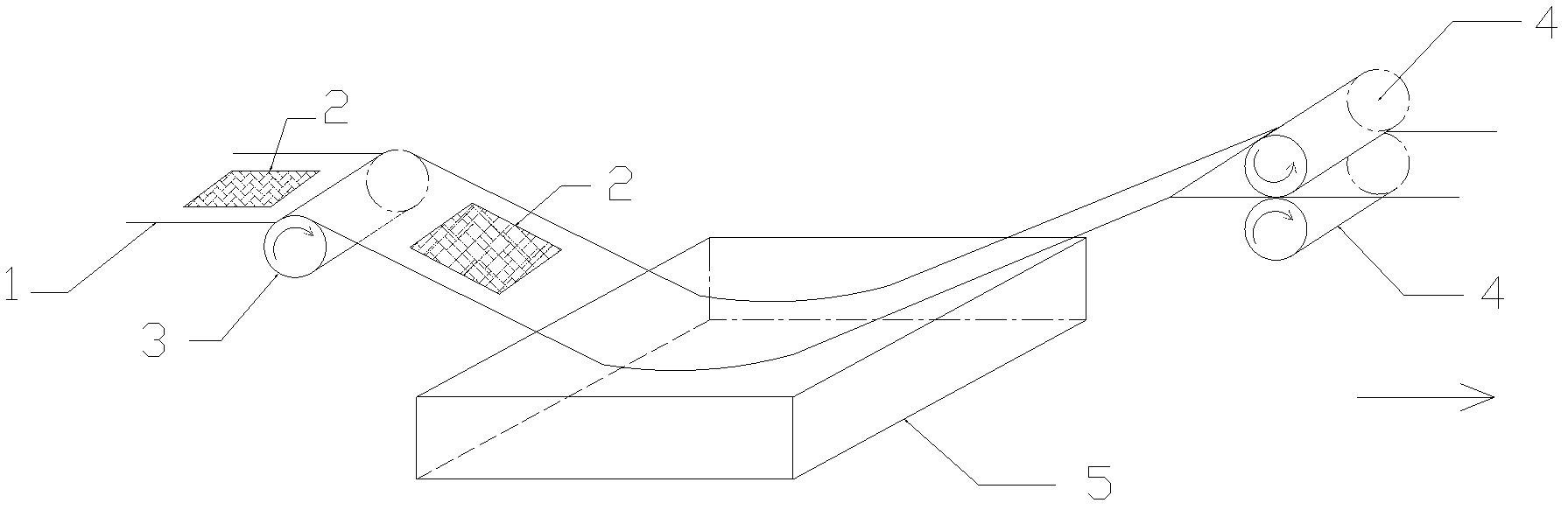

[0023] Collect nitrogen-doped nano-TiO 2 The fiber precursor is sent to the opening machine and the carding machine in turn for opening and carding, to remove the bamboo-shaped impurities in the fiber precursor, and to comb the fiber precursor into a single-filament fiber network, and place the obtained fiber network in a On the laying equipment, evenly staggered to form a five-layer fiber mesh structure, forming five layers of nitrogen-doped nano-TiO 2 Web 2 (see figure 1 ).

[0024] like figure 1 As shown, the laid fiber web 2 is introduced into the dipping tank 5 through the conveyor belt 1 for dipping, the conveyor belt 1 is driven by the rotating shaft 3, and the adhesive is composed of unsaturated polyester resin and tert-butyl perbenzoate. The mass ratio of the two is 100:8.2, and the impregnation is performed under normal pressure for 0.5 hours, so that the adhesive is fully impregnated into the fiber web. The dipped fiber web 2 is pressed by a pair of rollers 4 to...

Embodiment 2

[0026] According to the method of Example 1, ten layers of fiber mesh structure are uniformly staggered to form ten layers of nitrogen-doped nano-TiO 2 Web 2 (see figure 1 ).

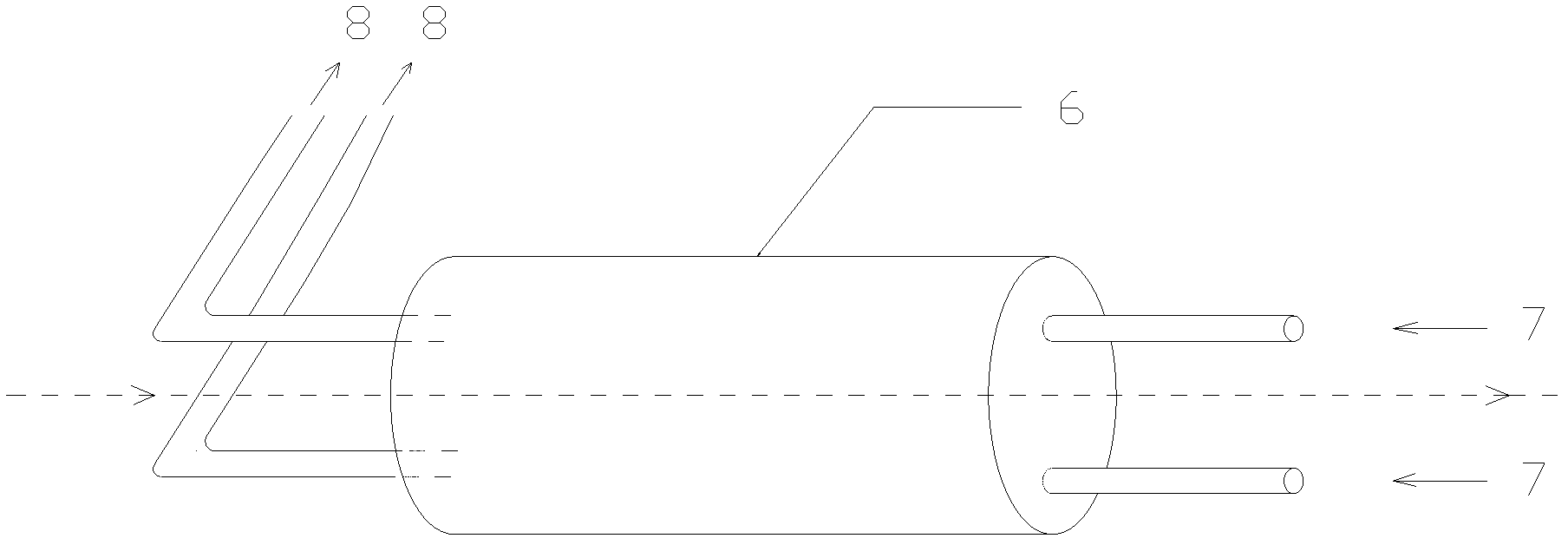

[0027] The laid fiber web is introduced into the dipping tank 5 through the conveyor belt 1 for dipping. The composition of the adhesive is a phenolic resin solution diluted with absolute ethanol, and the volume ratio of the two is 1.5-2.5:5. , so that the adhesive is fully impregnated into the fiber web. The fiber web after dipping is pressed by a pair of rollers 4 to remove excess adhesive on the surface. The fiber web after pressing is introduced into tube furnace 6 (see figure 2 ) at a rate of 150°C / hour to the solidification temperature of the adhesive at 140°C, and kept at 140°C for 2 hours to fully cure the adhesive. Water vapor is passed through the narrow tube 7, and the excess water vapor is discharged from the discharge pipe 8 to the outside, and at the same time, the temperature is rais...

Embodiment 3

[0029] According to the method of Example 1, a fifteen-layer fiber network structure is uniformly staggered to form fifteen layers of nitrogen-doped nano-TiO 2 Web 2 (see figure 1 ).

[0030] The laid fiber web is introduced into the dipping tank 5 through the conveyor belt 1 for dipping, and the adhesive is composed of epoxy resin, low molecular polyamide resin, polybutadiene epoxy, 2-ethyl-4-formaldehyde The mass ratio of imidazole and 260 epoxy reactive diluent is 100:10:20:5:12, impregnated under normal pressure for 5 hours, so that the adhesive is fully impregnated into the fiber web. The fiber web after dipping is pressed by a pair of rollers 4 to remove excess adhesive on the surface. The fiber web after pressing is introduced into tube furnace 6 (see figure 2 ) at a rate of 80°C / hour to the solidification temperature of the adhesive at 100°C, and kept at 100°C for 4 hours to fully cure the adhesive. Water vapor is passed through the narrow tube 7, and the excess w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com