Wide-temperature amylase production method

A production method and technology of amylase, applied in the field of bioengineering, can solve problems such as wide temperature amylase wide temperature amylase production method not reported and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Bevel formula (calculated in g / L)

[0050] Beef juice 4, peptone 10, yeast powder (yeast extract) 3, NaCl 3, starch 10, glucose 50, agar 15-25, culture temperature 35°C, culture time: 30h.

[0051] Shake bottle formula (calculated in g / L)

[0052] Bean cake powder 40, cottonseed cake powder 30, (NH 4 ) 2 SO 4 5. CaCl 2 0.5, corn steep liquor 30, lactose 150, sodium citrate 5, dipotassium hydrogen phosphate 15, potassium dihydrogen phosphate 7, culture temperature 40°C, culture time 30h.

[0053] Seed tank formula (calculated in g / L)

[0054] Glucose 75, yeast powder 30, cottonseed cake powder 15, ammonium sulfate 5, sodium citrate 8, CaCl 2 0.5, P.P.E. (polyether defoamer) 0.5, dipotassium hydrogen phosphate 7, potassium dihydrogen phosphate 7, fermentation temperature 35°C, ventilation 0.8 V.V.M, tank pressure 0.8 kg / cm 2 , Time 36 hours, seed tank volume: 500L, 60% charge.

[0055] Production tank formula (calculated in g / L)

[0056] Glucose 75, yeast pow...

Embodiment 2

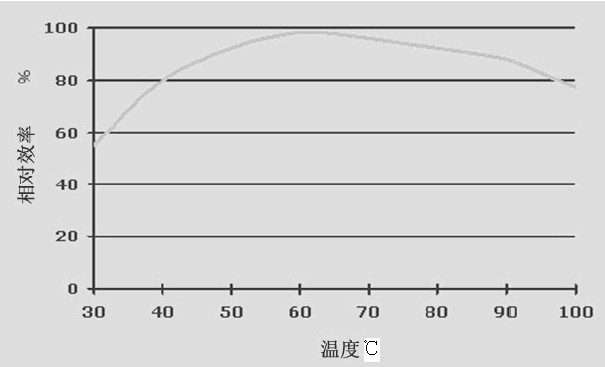

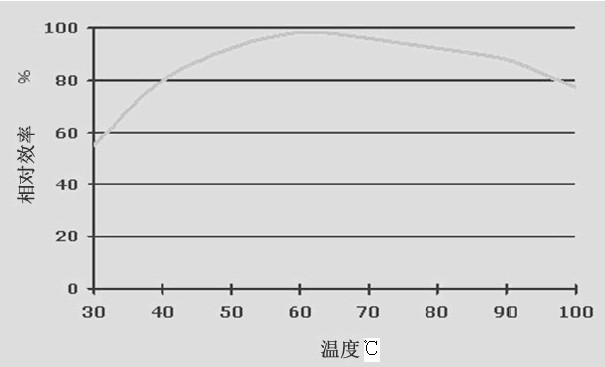

[0059] The broad temperature amylase that embodiment 1 makes, the relation of its temperature of reaction and reaction efficiency is as figure 1 shown in the curve. It is shown that the action temperature range of the amylase can be 30-100°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com