ABS (Acrylonitrile Butadiene Styrene) environment-friendly inflaming retarding compound material and preparation method thereof

A flame-retardant composite material and environmentally friendly technology, applied in the field of polymer materials, can solve the problems of high production costs, and achieve the effects of convenient operation, simple preparation, and easy industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

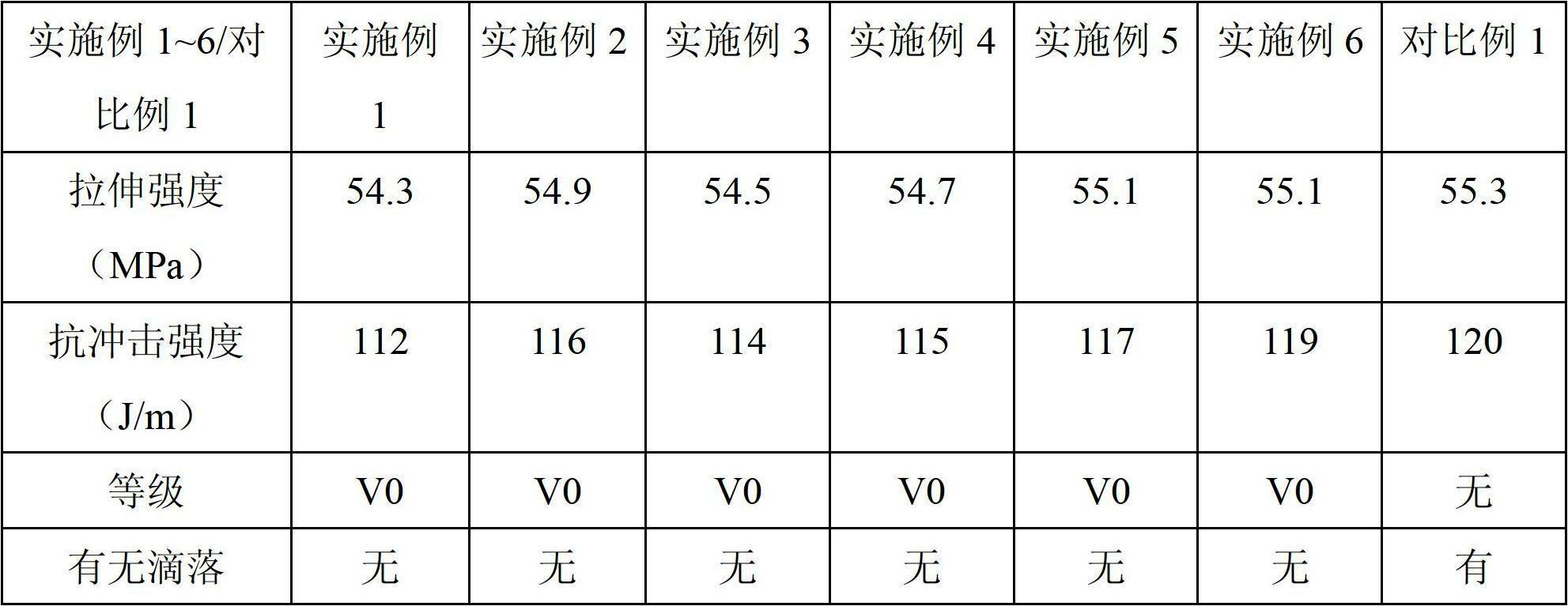

Examples

Embodiment 1

[0037] 1) Vacuum-dry halloysite (200 mesh, Jinbo Mineral Products Processing Plant, Lingshou County) at 80°C for 4 hours and set aside;

[0038] 2) Weigh 4.8 kg of ABS (Taiwan Taihua, AG12A0, melt index 17), bromotriazine (Shouguang Guangda Industry and Trade Co., Ltd., FR-245, TTBPC) 1.6 kg, antimony trioxide (Yuyao Fenfa Plastic Co., Ltd.) Industry Co., Ltd.) 0.8 kg, compound silicate material 0.72 kg (composed of 0.32 kg halloysite and 0.4 kg montmorillonite) and PTFE (Cixi Henghe Wangwang Plastic Products Factory, weight average molecular weight 450~500 Ten thousand) 0.08 kg is pre-mixed in a pre-mixer (220 rpm) to obtain a mixed material;

[0039] 3) Add the mixed materials into a twin-screw extruder for melt blending, extrude, and granulate to obtain granular ABS environmentally friendly flame-retardant composite materials. Among them, the temperature of each section of the mixed material in the twin-screw extruder is respectively: the temperature of the feeding section...

Embodiment 2

[0042] 1) Vacuum-dry halloysite (200 mesh, Jinbo Mineral Products Processing Plant, Lingshou County) at 80°C for 4 hours and set aside;

[0043] 2) Weigh 6.4 kg of ABS (Taiwan Taihua, AG12A0, with a melt index of 17), 0.88 kg of bromotriazine (Shouguang Guangda Industry and Trade Co., Ltd., FR-245, TTBPC), and 0.88 kg of antimony trioxide (Yuyao Fenfa Plastic Co., Ltd. Industry Co., Ltd.) 0.32 kg, compound silicate material 0.32 kg (composed of 0.16 kg halloysite and 0.16 kg montmorillonite) and PTFE (Cixi Henghe Wangwang Plastic Products Factory, weight average molecular weight 450~500 Ten thousand) 0.08 kg is pre-mixed in a pre-mixer (220 rpm) to obtain a mixed material;

[0044] 3) Add the mixed materials into a twin-screw extruder for melt blending, extrude, and granulate to obtain granular ABS environmentally friendly flame-retardant composite materials. Among them, the temperature of each section of the mixed material in the twin-screw extruder is respectively: the temp...

Embodiment 3

[0047] 11) Vacuum-dry halloysite (200 mesh, Jinbo Mineral Products Processing Plant, Lingshou County) at 80°C for 4 hours and set aside;

[0048] 2) Weigh 6.0 kg of ABS (Taiwan Taihua, AG12A0, with a melt index of 17), 0.8 kg of bromotriazine (Shouguang Guangda Industry and Trade Co., Ltd., FR-245, TTBPC), and 0.8 kg of antimony trioxide (Yuyao Fenfa Plastic Co., Ltd. Industry Co., Ltd.) 0.4 kg, 0.72 kg of compound silicate material (composed of 0.32 kg of halloysite and 0.4 kg of montmorillonite) and PTFE (Cixi Henghe Wangwang Plastic Products Factory, weight average molecular weight 450~500 10,000) 0.08 kg is pre-mixed in a pre-mixer (200 rpm) to obtain a mixed material;

[0049] 3) Add the mixed materials into a twin-screw extruder for melt blending, extrude, and granulate to obtain granular ABS environmentally friendly flame-retardant composite materials. Among them, the temperature of each section of the mixed material in the twin-screw extruder is respectively: the temp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com