Preparation method for TiO2 nanotube array film with high catalytic properties and application of TiO2 nanotube array film

A nanotube array and thin film technology, applied in the field of photocatalysis, can solve the problems of slow photocatalytic reaction rate, unsatisfactory catalytic performance, low utilization rate of sunlight, etc., and achieve optimized anatase crystallinity, high commercial value, catalytic Excellent efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] (1) Place the metal Ti sheet in acetone, ethanol and deionized water in sequence, wash it for 10 minutes respectively, and dry it with high-pressure nitrogen as the anode;

[0040] (2) Metal Mo is used as the cathode. Using an ethylene glycol solution of 0.09mol / L ammonium fluoride and 1.8wt.% deionized water as the electrolyte, pass a 60V DC voltage between the two electrodes and keep it for 1 hour to obtain amorphous TiO 2 nanotube array films (such as figure 1 shown);

[0041] (3) TiO 2 The thin film is placed in a crucible, in pure N 2 Annealing is performed in a mixed gas atmosphere of gas and water vapor. The temperature rise rate of the annealing furnace is set at 10°C / min, and the temperature is raised to 200°C for 0.5 hours, and the gas flow rate is in the range of 0.4 liters / min.

Embodiment 2

[0043] Preparation of TiO by anodic oxidation 2 The implementation steps of the nanotube array thin film are the same as (1) (2) of Example 1.

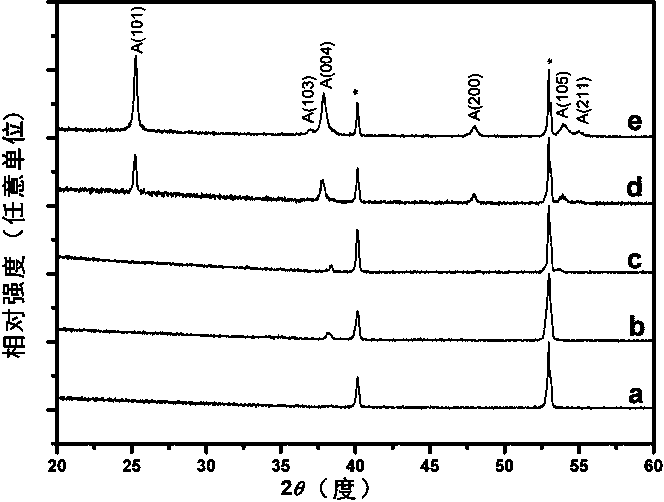

[0044] The heating rate of the annealing furnace is set at 10°C / min, and the pure N 2 Under the atmosphere, the temperature was raised to 200 ° C and kept for 0.5 hours, and the TiO was annealed according to the step (3) of Example 1. 2 Nanotube Array Films. Gained sample utilizes XRD to test its degree of crystallization, the result is as follows figure 2 Shown in the b curve.

[0045] The temperature rise rate of the annealing furnace is set at 10°C / min, and the pure N in the annealing atmosphere 2 Mixed with water vapor, the temperature was raised to 200 ° C and kept for 0.5 hours, according to the step (3) of Example 1 to anneal TiO 2 Nanotube Array Films. Gained sample utilizes XRD to test its degree of crystallization, the result is as follows figure 2 The middle c curve is shown.

[0046] XRD shows that at 200 °C, the...

Embodiment 3

[0049] Preparation of TiO by anodic oxidation 2 The implementation steps of the nanotube array are the same as (1) (2) of Embodiment 1.

[0050] The same as embodiment 2 for the annealing treatment step of sample, obtain sample and utilize XRD to test its degree of crystallization, the result is as follows figure 2 In b, c curve shown.

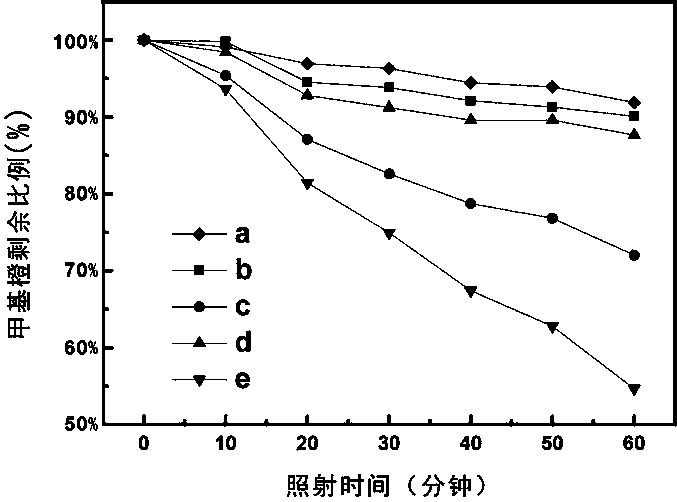

[0051] Compare the photocatalytic efficiency of two kinds of samples, take Rhodamine b as the target degradation dye, the experimental procedure is the same as that described in Example 2, pure N 2 The degradation results of atmosphere annealed samples are as follows: Figure 4 As shown in the b curve, the degradation results of the samples mixed with water vapor annealing are as follows Figure 4 The middle c curve is shown. where pure N 2 The degradation efficiency of rhodamine b within 1 hour of atmosphere annealed sample was 21.58%, and the degradation efficiency of sample mixed with water vapor annealed was 31.19%, and the latter wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com