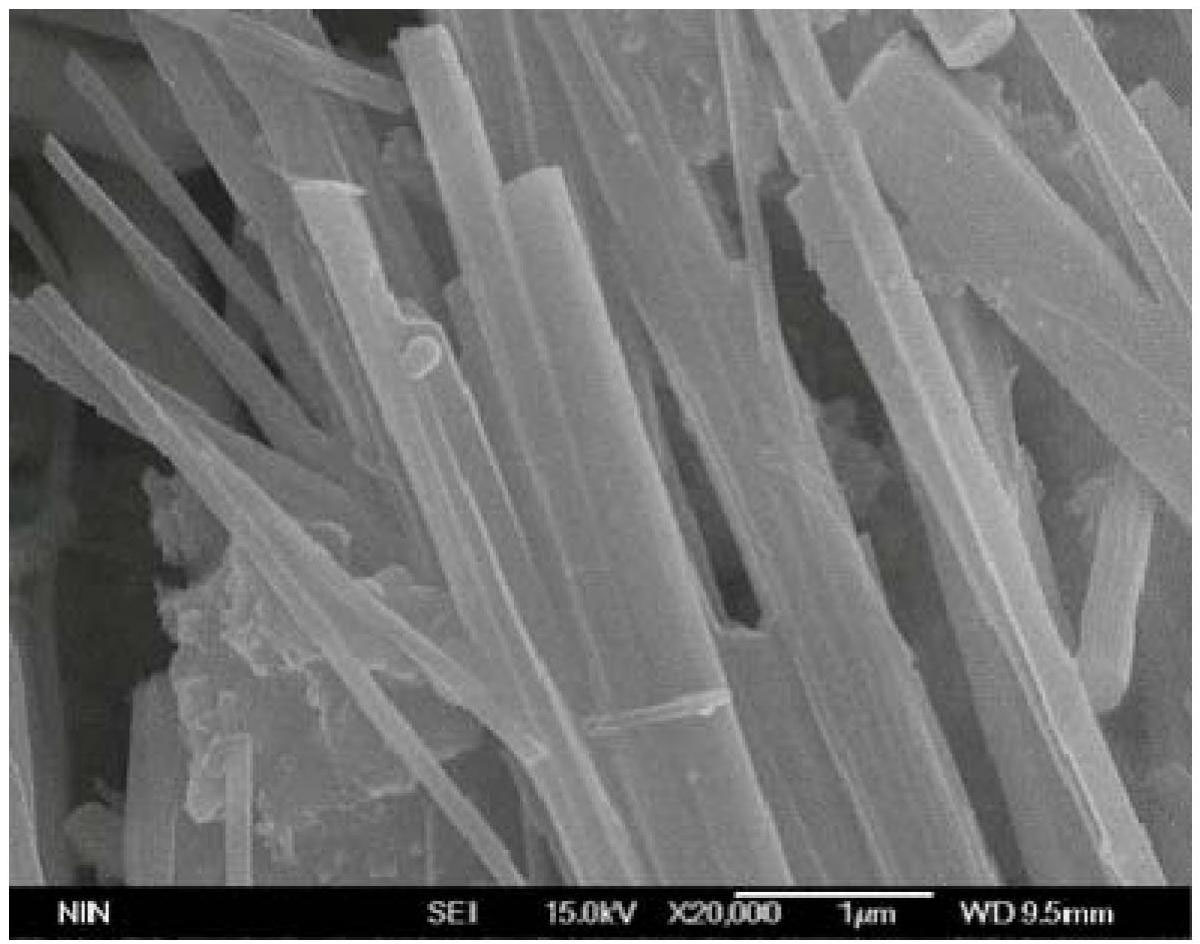

Preparation method of Y4Si3O12 crystal whiskers

A technology of whisker and 3·6H2O, which is applied in the field of Y4Si3O12 preparation, can solve the problems of low and high temperature oxygen permeability and achieve the effects of low preparation temperature, uniform particle size and avoiding grain growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] 1) Take analytically pure Y(NO) 3 ·6H 2 O, Na 2 SiO 3 9H 2 O, according to the molar ratio of Y: Si = 1: 1.2, dissolved in absolute ethanol to prepare Y 3+ A solution with a concentration of 0.36mol / L was adjusted to pH=7 with a NaOH solution with a concentration of 3mol / L to obtain solution A;

[0019] 2) Press Y into Solution A 3+ : EDTA:HEPE=1:0.4:0.05 molar ratio, add analytically pure EDTA and HDPE as a template, stir magnetically at room temperature for 0.5h, mix evenly, and then ultrasonically react for 1h, ultrasonic power is 500W, to obtain solution B;

[0020] 3) Put solution B in a polytetrafluoroethylene-lined hydrothermal kettle, control the filling ratio to 40%, then put the reaction kettle into a constant temperature reactor, and react at 210°C for 48h;

[0021]4) The reaction system was naturally cooled to room temperature, centrifuged, washed three times with distilled water and absolute ethanol, and finally dried in an electric blast drying oven ...

Embodiment 2

[0023] 1) Take analytically pure Y(NO) 3 ·6H 2 O, Na 2 SiO 3 9H 2 O, according to the molar ratio of Y: Si = 1: 1.8, dissolved in absolute ethanol to prepare Y 3+ A solution with a concentration of 0.86 mol / L was adjusted to pH=9 with a NaOH solution with a concentration of 3 mol / L to obtain solution A;

[0024] 2) Press Y into Solution A 3+ : EDTA:HEPE=1:1.5:0.09 molar ratio, add analytically pure EDTA and HDPE as a template, stir magnetically at room temperature for 2 hours, mix well, and then ultrasonically react for 3 hours, ultrasonic power is 300W, to obtain solution B;

[0025] 3) Put solution B in a polytetrafluoroethylene-lined hydrothermal kettle, control the filling ratio to 60%, then put the reaction kettle into a constant temperature reactor, and react at 140°C for 72h;

[0026] 4) The reaction system was naturally cooled to room temperature, centrifuged, washed with distilled water and absolute ethanol for 5 times, and finally dried in an electric blast dry...

Embodiment 3

[0029] 1) Take analytically pure Y(NO) 3 ·6H 2 O, Na 2 SiO 3 9H 2 O, according to the molar ratio of Y: Si = 1: 1.5, dissolved in absolute ethanol to prepare Y 3+ A solution with a concentration of 0.61mol / L was adjusted to pH=8 with a NaOH solution with a concentration of 3mol / L to obtain solution A;

[0030] 2) Press Y into Solution A 3+ : EDTA:HEPE=1:0.95:0.07 molar ratio, add analytically pure EDTA and HDPE as a template, stir magnetically at room temperature for 1h, mix well, then ultrasonically react for 2h, ultrasonic power is 400W, to obtain solution B;

[0031] 3) Put solution B in a polytetrafluoroethylene-lined hydrothermal kettle, control the filling ratio to 50%, then put the reaction kettle into a constant temperature reactor, and react at 175°C for 60h;

[0032] 4) The reaction system was naturally cooled to room temperature, centrifuged, washed with distilled water and absolute ethanol for 4 times, and finally dried in an electric blast drying oven at 65°...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com