Method for preparing sulfuric acid by catalytically oxidizing low-concentration sulfur dioxide in baking flue gas

A sulfur dioxide, catalytic oxidation technology, applied in chemical instruments and methods, separation methods, inorganic chemistry and other directions, can solve the problems of high operation and maintenance costs, only a large number of stacking, and difficult wastewater treatment, and achieves a broad sales market and low production costs. , No secondary pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

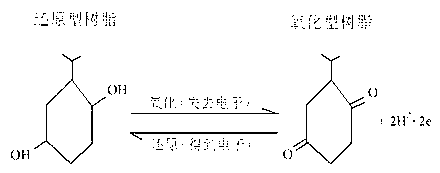

Image

Examples

specific Embodiment

[0035] Specific examples: a vanadium pentoxide production plant with an annual output of 1,500 tons, the process of extracting vanadium is to use vanadium-containing stone coal as raw material, decarbonized by boiling roasting, vanadium is extracted by acid leaching of the decarbonized material, and the vanadium-containing stone coal is treated daily 400 tons, the average mass percentage of vanadium-containing stone coal sulfur content is 2.70%, and the removal rate of sulfur is 64.20%. Iron oxide can catalyze the oxidation of sulfur dioxide to sulfur trioxide at high temperature. The oxidation rate of sulfur dioxide is as high as 86.45%. The dust removal layer, the second, third, and fourth layers are filled with a 30cm thick wet electron exchange resin layer, and the fifth layer is a layer for installing a mist eliminator. The flue gas passes through the bottom of the spray absorption tower for spray cooling and dust removal. Before the cooling spray liquid is filtered, 5% h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxidation rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com