Method for preparing granular ammonium sulfate and calcium carbonate by chemical gypsums via low-temperature transformation

A chemical gypsum and low-temperature conversion technology, applied in the field of phosphorus chemical industry, can solve the problems of chemical gypsum environmental pollution ammonium sulfate production costs, etc., to achieve the effect of avoiding secondary pollution, reducing investment costs and operating costs, and reducing procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

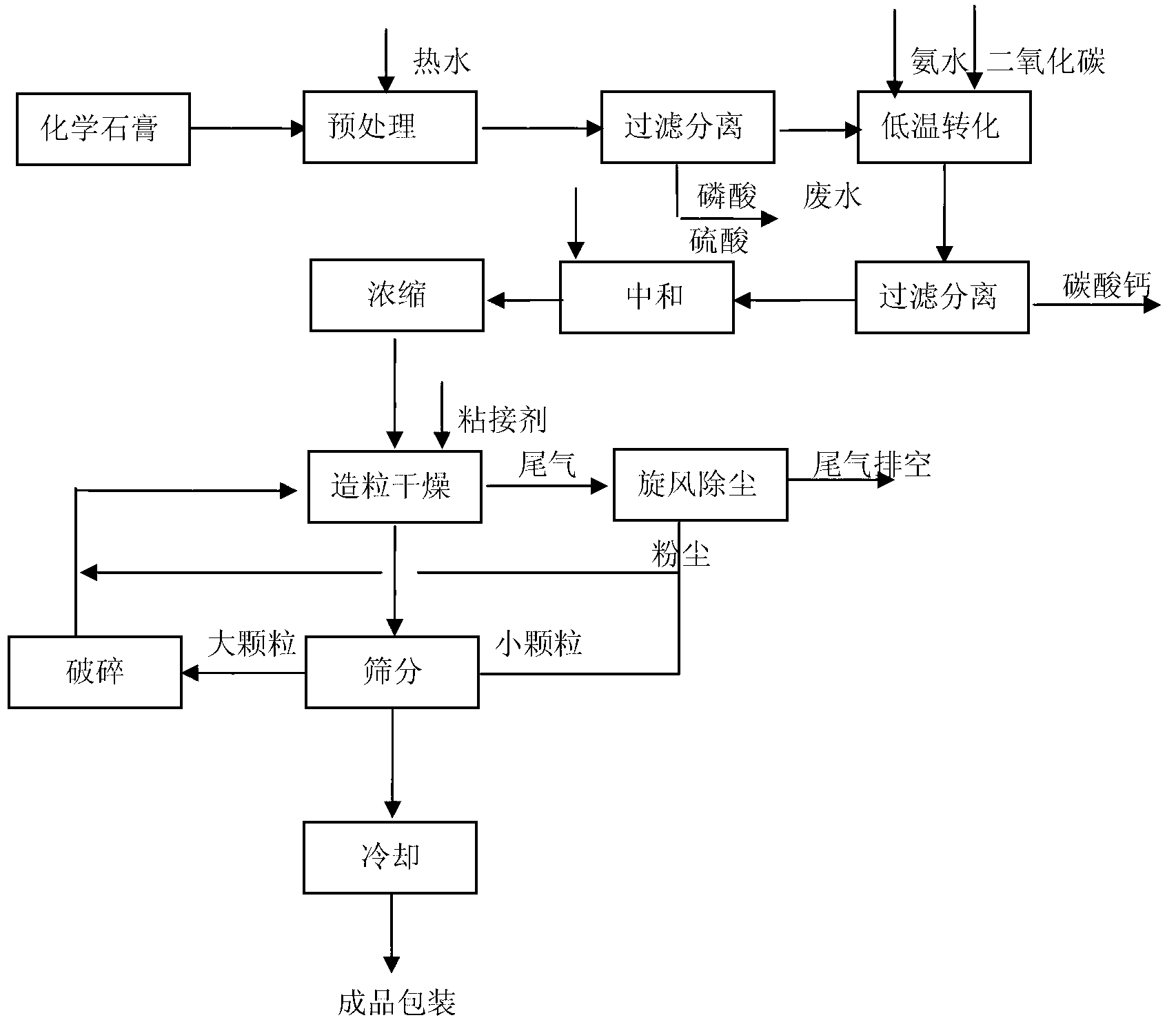

[0028] Such as figure 1 As shown, (1) first pretreat seven kinds of chemical gypsum including phosphogypsum, flue gas desulfurization FGD gypsum, fluorine gypsum, citrate gypsum, boron gypsum, titanium gypsum and Glauber’s salt gypsum, and wash them with hot water at 70°C to remove the water-soluble phosphorus , sulfur trioxide, and soluble salts of potassium, sodium, magnesium, and aluminum; returned to the phosphoric acid, ammonium phosphate production system, used as process water for recycling, or sent to the sewage treatment plant for discharge after reaching the standard.

[0029] (2) Use the pretreated chemical gypsum to prepare ammonium sulfate solution to produce calcium carbonate raw materials that meet the requirements of Portland cement production;

[0030] (2.1) Add water to the chemical gypsum from (1) to re-slurry, adjust the pH value of the solution to about 8 with ammonia gas, keep it at a temperature of 45°C, and carry out metathesis reaction by passing carbo...

Embodiment 2

[0038] Such as figure 1 As shown, (1) first pretreat seven kinds of chemical gypsum including phosphogypsum, flue gas desulfurization FGD gypsum, fluorine gypsum, citrate gypsum, borogypsum, titanium gypsum and Glauber’s salt gypsum. Wash with water to remove water-soluble phosphorus, sulfur trioxide, and soluble salts of potassium, sodium, magnesium, and aluminum; return to the phosphoric acid and ammonium phosphate production system, and reuse it as process water, or send it to the sewage treatment plant for treatment and discharge after reaching the standard.

[0039] (2) Use the pretreated chemical gypsum to prepare ammonium sulfate solution to produce calcium carbonate raw materials that meet the requirements of Portland cement production;

[0040] (2.1) Add water to the chemical gypsum from (1) for reslurry, and adjust the pH value of the solution to about 10 with ammonia gas, keep it at a temperature of 50°C, and carry out metathesis reaction by passing carbon dioxide g...

Embodiment 3

[0048] Such as figure 1 As shown, (1) first pretreat seven kinds of chemical gypsum including phosphogypsum, flue gas desulfurization FGD gypsum, fluorine gypsum, citrate gypsum, borogypsum, titanium gypsum and Glauber’s salt gypsum. Wash with water to remove water-soluble phosphorus, sulfur trioxide, and soluble salts of potassium, sodium, magnesium, and aluminum; return to the phosphoric acid and ammonium phosphate production system, and reuse it as process water, or send it to the sewage treatment plant for treatment and discharge after reaching the standard.

[0049] (2) Use the pretreated chemical gypsum to prepare ammonium sulfate solution to produce calcium carbonate raw materials that meet the requirements of Portland cement production;

[0050] (2.1) Add water to the chemical gypsum from (1) for reslurry, and adjust the pH value of the solution to about 8 with ammonia gas, and keep it at a temperature of 45°C. Introduce carbon dioxide gas to make it undergo double de...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com