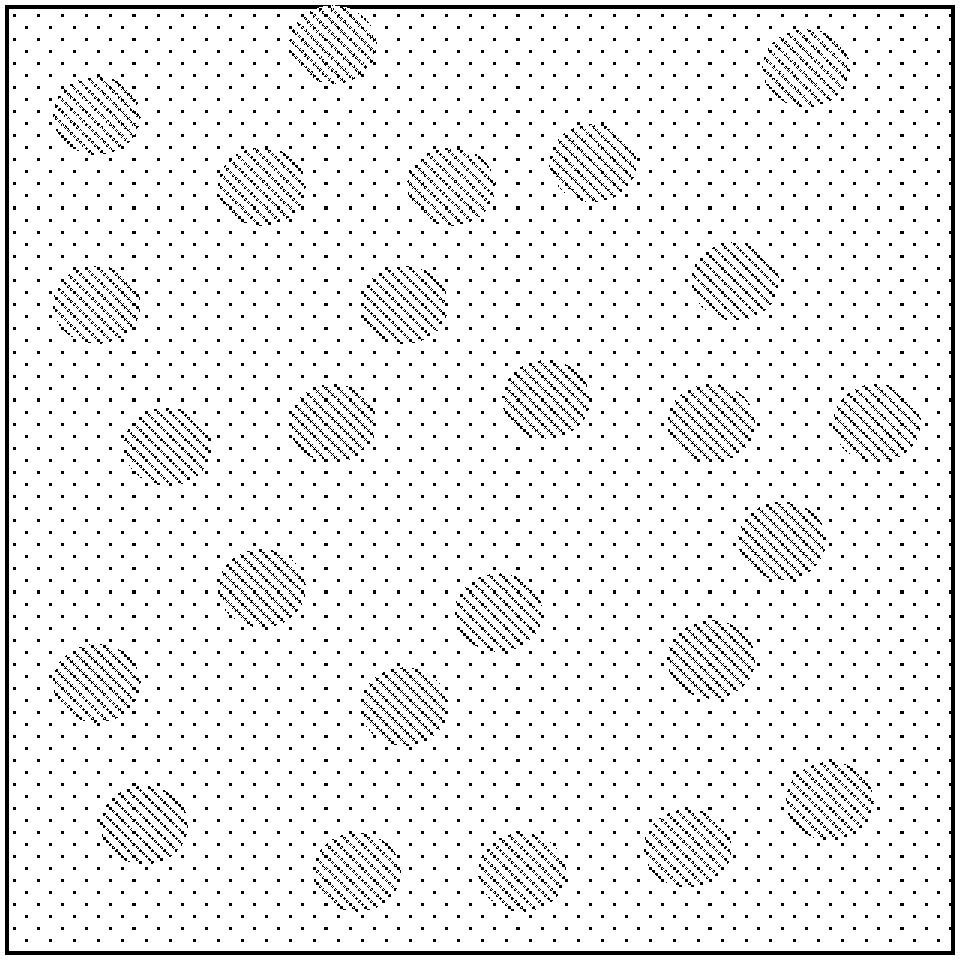

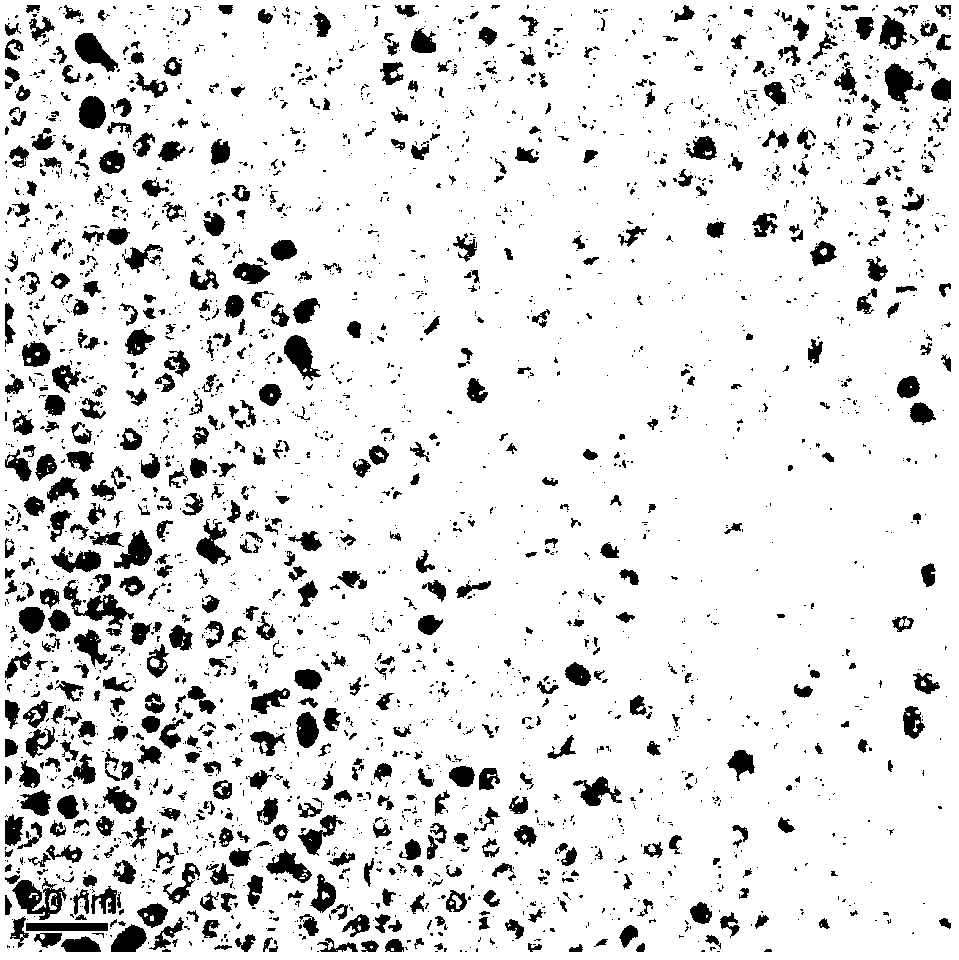

Nickel-copper alloy liquid for chemical plating and electroplating and method for preparing nickel-copper alloy noncrystalline-based composite coating

A nickel-copper alloy, composite coating technology, applied in liquid chemical plating, metal material coating process, coating and other directions, can solve the problem of small amorphous nanocrystalline composite coating and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

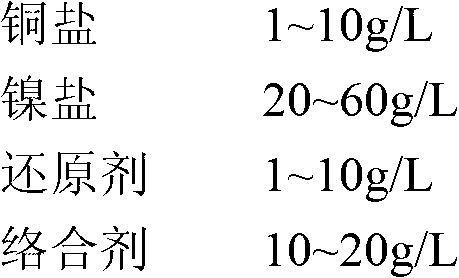

Embodiment 1

[0031] In this example:

[0032] The formula of nickel-copper alloy liquid for electroless plating-electroplating is: solvent is deionized water, copper phosphate 8g / L, nickel sulfate 20g / L, hydrazine hydrate 1g / L, boric acid 10g / L.

[0033] The preparation process of using the above-mentioned nickel-copper alloy liquid electroless plating-electroplating to prepare the nickel-copper alloy amorphous matrix composite coating is as follows:

[0034] (1) The metal substrate is low-carbon steel; the surface of the metal substrate is pretreated to remove oil and oxide film. The specific process is: add an appropriate amount of sodium lauryl sulfate to a NaOH solution with a concentration of 10% by mass to obtain a mixed Solution, the concentration of sodium lauryl sulfate in the mixed solution is 1g / l, put the metal substrate into the mixed solution, wash at a cleaning temperature of 50°C for 8 minutes, and then use mechanical polishing to oxidize the surface of the metal substrate ...

Embodiment 2

[0055] In this example:

[0056] The formula of nickel-copper alloy liquid for electroless plating-electroplating is: solvent is deionized water, copper chloride 2g / L, nickel chloride 15g / L, dimethylaminoborane 2g / L, sodium citrate 20g / L.

[0057] The preparation process of using the above-mentioned nickel-copper alloy liquid electroless plating-electroplating to prepare the nickel-copper alloy amorphous matrix composite coating is as follows:

[0058] (1) The metal substrate is low-carbon steel; the surface of the metal substrate is pretreated to remove oil and oxide film. The specific process is: add an appropriate amount of sodium lauryl sulfate to a KOH solution with a concentration of 15% by mass to obtain a mixed solution, the concentration of sodium lauryl sulfate in the mixed solution is 5g / l, put the metal substrate into the mixed solution, wash at a cleaning temperature of 60°C for 5 minutes, and then use chemical polishing to oxidize the surface of the metal substra...

Embodiment 3

[0063] In this example:

[0064] The formula of nickel-copper alloy liquid for electroless plating-electroplating is: solvent is deionized water, copper phosphate 6g / L, nickel sulfate 25g / L, formaldehyde 1.5g / L, potassium sodium pyrophosphate 12g / L.

[0065] The preparation process of using the above-mentioned nickel-copper alloy liquid electroless plating-electroplating to prepare the nickel-copper alloy amorphous matrix composite coating is as follows:

[0066] (1) The metal substrate is low-carbon steel; the surface of the metal substrate is pretreated to remove oil and oxide film. The specific process is: add an appropriate amount of sodium lauryl sulfate to a KOH solution with a concentration of 12% by mass to obtain a mixed solution, the concentration of sodium lauryl sulfate in the mixed solution is 6g / l, the metal substrate is put into the mixed solution, and cleaned at a cleaning temperature of 40°C for 10 minutes, and then the surface of the metal substrate is oxidiz...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com