Method for purifying phosphine tail gas from fumigation

A tail gas purification and phosphine technology, applied in the field of air purification, can solve the problems of small air volume, poor practicability, waste of oxidant, etc., and achieve the effect of low energy consumption and small resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

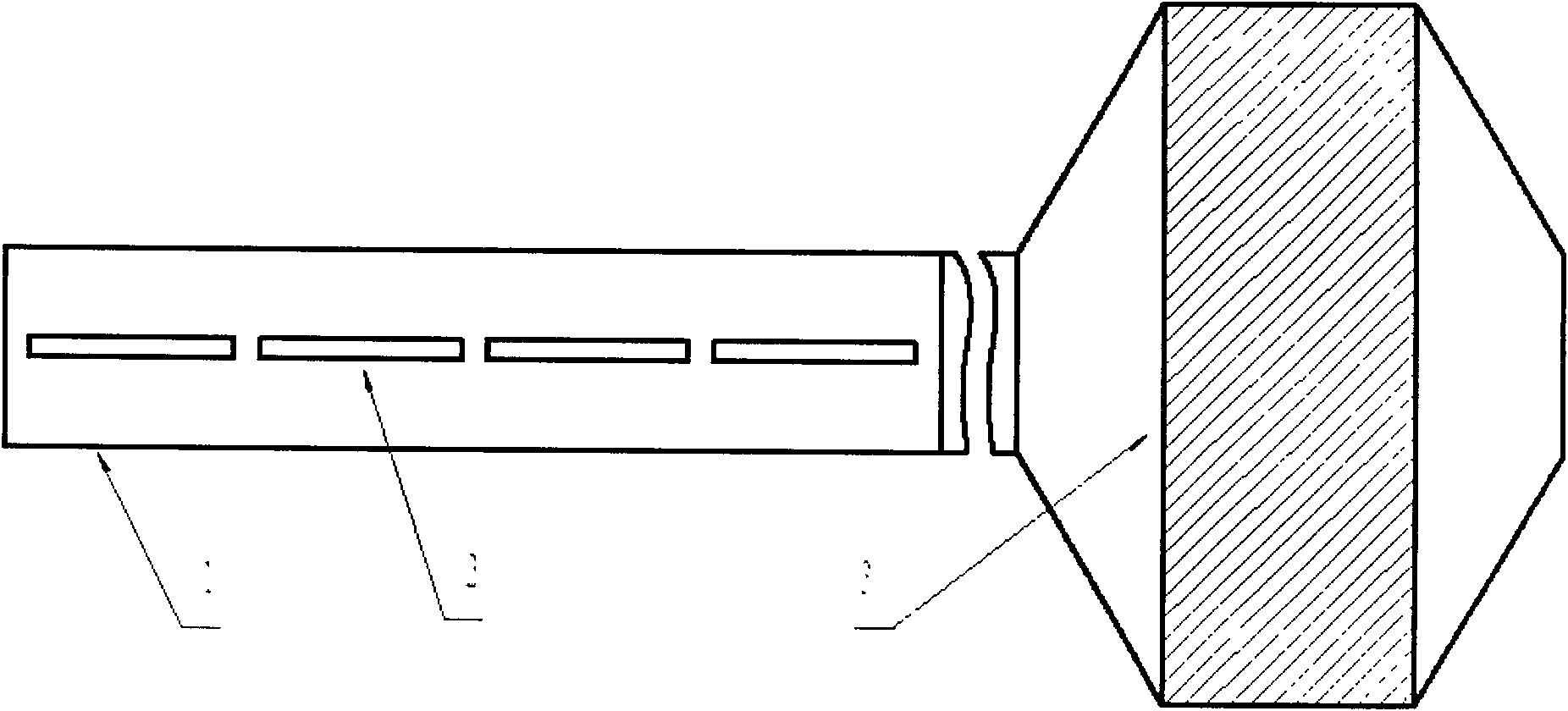

[0032] Such as figure 1 As shown, the ventilation pipeline (1) is a stainless steel cylinder with a diameter of 20cm and a length of 60cm, with a cross-sectional area of 314cm 2 , the vacuum ultraviolet light source (2) is a low-pressure mercury lamp with a power of 23W, which is suspended at the center of the ventilation pipeline (1), and the activated carbon filter (3) is a cylindrical tube with a diameter of 4cm, and coal with a particle size of 1.5mm is installed inside. Quality activated carbon, filling thickness 6cm.

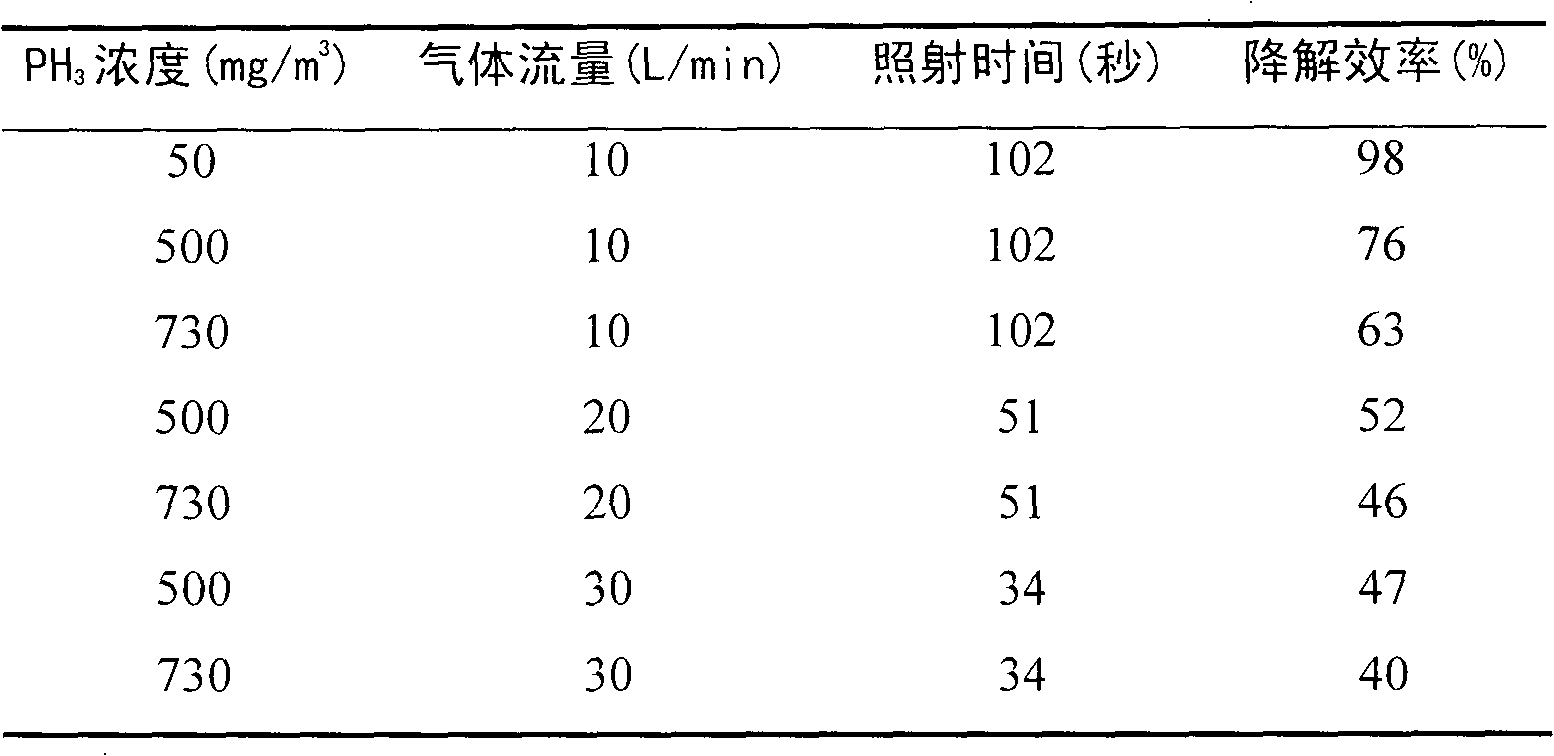

[0033] Different concentrations of phosphine gas occur respectively, and at different gas flow rates, investigate the purification effect of the present invention on phosphine, test the concentration of phosphine in the tail gas of the active carbon filter (3), calculate the purification efficiency of phosphine, and test results As shown in Table 1.

[0034] Table 1 Power is 23W low-pressure mercury lamp on the purification effect of phosphine

[0035...

Embodiment 2

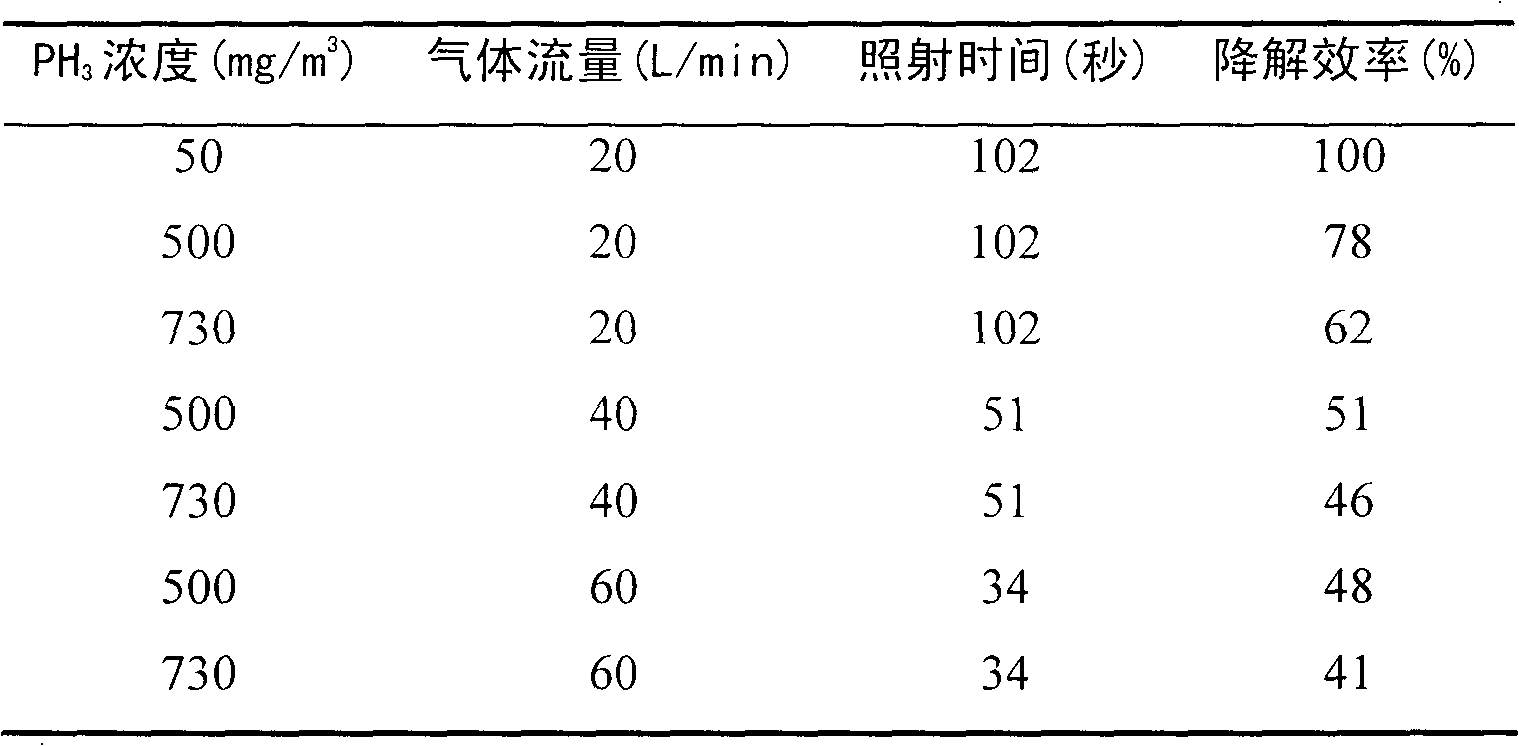

[0037] The ventilation pipeline (1) is composed of two stainless steel cylinders with a diameter of 20cm and a length of 60cm connected in series, with a cross-sectional area of 314cm 2 , the vacuum ultraviolet light source (2) is two low-pressure mercury lamps with a power of 23W, which are suspended in the center of two stainless steel cylinders, and the activated carbon filter (3) is a cylindrical tube with a diameter of 6cm, and the coal particle size of 1.5mm is contained inside Activated carbon, filling thickness 6cm. Compared with Example 1, the ventilation pipeline length is doubled in this example, the air volume is also doubled, the irradiation power per unit area is the same, and the irradiation time is also the same. The results of the phosphine purification test are shown in Table 2.

[0038] Table 2 Purification effect of phosphine by a low-pressure mercury lamp with a power of 46W

[0039]

Embodiment 3

[0041] The ventilation pipeline (1) is a hollow cuboid surrounded by iron sheets with a square cross-section, with a side length of 25cm, a length of 60cm, and a cross-sectional area of 625cm 2 , the vacuum ultraviolet light source (2) is a low-pressure mercury lamp with a power of 23W, suspended in the central position of the cuboid, the activated carbon filter (3) is a cylindrical tube with a diameter of 6 cm, and the coal-based activated carbon with a particle size of 1.5 mm is installed inside, and the thickness of the filling is 6cm. Compared with Embodiment 1, the cross-sectional area of the ventilation pipeline in this example is doubled, the air volume is also doubled, and the irradiation power is the same. The results of the phosphine purification test are shown in Table 2.

[0042] Table 3 Purification effect of low-pressure mercury lamp power 92 watts on phosphine

[0043]

[0044]For the treatment of phosphine fumigation tail gas with a large air volume an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com