Preparation method of ATP/ Ce-Ti sold soluble oxide composite material

A technology of attapulgite and nano-composite material is applied in the field of preparation of attapulgite/cerium-titanium solid solution oxide nano-composite material, which can solve the problems of difficult separation and recovery of catalyst powder, restricting catalyst and the like, and achieves high industrial popularization. Value, good experimental repeatability, uniform load effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Example 1: First, 0.0016 mol of cerium nitrate, 0.0016 mol of tetrabutyl titanate and 20 mL of absolute ethanol with a cerium-titanium molar ratio of 5:5 were uniformly mixed under magnetic stirring in a water bath at 30°C as component A; 10 mL of absolute ethanol, 3 mL of deionized water and 0.2 g of glacial acetic acid were mixed and stirred until a colorless and transparent solution was formed, which was used as component B; slowly drop component B into component A under continuous stirring conditions, and then use Concentrated nitric acid was used to adjust the pH to 4 to obtain solution C. Add 1 g of attapulgite and continue to stir for 24 h. It was placed in a constant temperature box at 60 °C for several days to form a xerogel, and it was calcined at 400 °C for 3 h to obtain Attapulgite supported CeO 2 -TiO 2 (Ce:Ti=5:5) composite material.

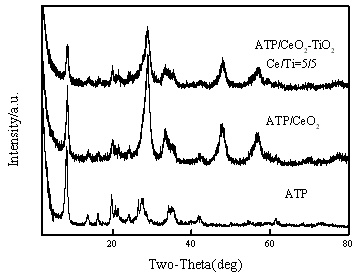

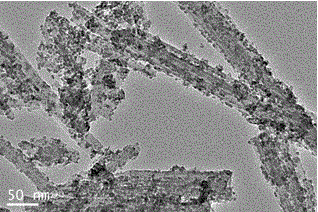

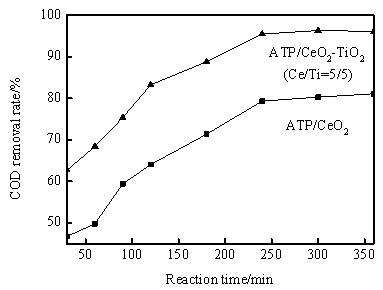

[0017] The obtained sample was subjected to X-ray powder diffraction experiment, and its morphology and structure were...

Embodiment 2

[0020] Example 2: Change the molar ratio of cerium to titanium to 9:1, the cerium salt is cerium chloride, the titanium alkoxide is titanium isopropoxide, the addition amount of cerium chloride is 0.00225 mol, and the addition amount of titanium isopropoxide is 0.00025 mol , the mass of attapulgite is 0.5 g, the complexing agent is changed to cetyltrimethylammonium bromide, the mass of cetyltrimethylammonium bromide is 0.8 g, the reaction is carried out in a water bath at 20°C for 24 h, and then After calcination at 200°C for 2 h, the subsequent detection results are as in Example 1.

Embodiment 3

[0021] Example 3: Change the cerium-titanium molar ratio to 3:7, the cerium salt is cerium acetate, the titanium alkoxide is titanium isopropoxide, the addition amount of cerium acetate is 0.0011 mol, the addition amount of titanium isopropoxide is 0.0026 mol, the unevenness The mass of the rod stone was 1 g, and the complexing agent was changed to citric acid, and the mass of citric acid was 0.2 g. It was reacted in a water bath at 40°C for 24 hours, and calcined at 400°C for 2 hours. The subsequent detection results were as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com