Solvent-free epoxy weight anticorrosion paint used for coated joints of steel buried pipeline

A buried pipeline, solvent-free technology, used in anti-corrosion coatings, epoxy resin coatings, coatings, etc., can solve the problems of poor water resistance, difficult construction, and large environmental impact of powder epoxy coatings, and improve thixotropy Effects and low viscosity, improved corrosion resistance, long pot life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

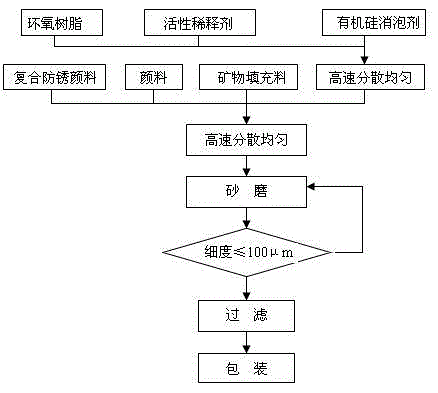

Method used

Image

Examples

Embodiment 1

[0039] In Example 1, the epoxy resin grade is E51, the reactive diluent is cresyl glycidyl ether, the silicone defoamer grade is BYK-A530, the composite antirust pigment is composite iron-titanium powder, and other mineral fillers are talcum powder , other pigments are iron oxide red, polyamide wax is ULTRA amide wax from CRAY VALLY company, barium sulfate mineral filler is 500 mesh barite powder, Mannich base curing agent is T31 curing agent, polyamide curing agent is Corning The company's grade is 125 polyamide curing agent, and the curing accelerator is DMP-30.

Embodiment 2

[0040] In Example 2, the grade of epoxy resin is E44, the reactive diluent is phenyl glycidyl ether, the grade of silicone defoamer is BYK-A530, the composite antirust pigment is composite iron-titanium powder, and other mineral fillers are feldspar powder , other pigments are titanium dioxide, polyamide wax is ULTRA amide wax from CRAY VALLY company, barium sulfate mineral filler is 500 mesh barite powder, Mannich base curing agent is T31 curing agent, polyamide curing agent is CRAY VALLY company The grade is 140 polyamide curing agent, and the curing accelerator is DMP-30.

Embodiment 3

[0041] In Example 3, the grade of epoxy resin is E52, the reactive diluent is butyl glycidyl ether, the grade of silicone defoamer is BYK-A530, the composite antirust pigment is composite iron-titanium powder, and other mineral fillers are mica powder , other pigments are iron oxide black, polyamide wax is ULTRA amide wax from CRAY VALLY company, barium sulfate mineral filler is 500 mesh barite powder, Mannich base curing agent is T31 curing agent, polyamide curing agent is Corning The company brand is 150 polyamide curing agent, and the curing accelerator is DMP-30.

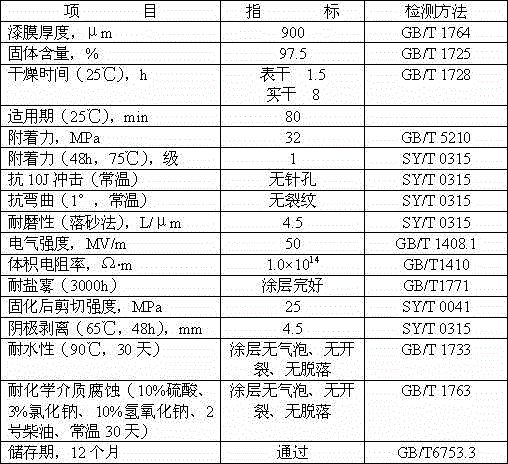

[0042] The main technical index of table 3, embodiment 2

[0043]

PUM

| Property | Measurement | Unit |

|---|---|---|

| amine value | aaaaa | aaaaa |

| epoxy value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com