Nano coating and preparation method and application thereof

A nano-coating and nano-material technology, applied in polyester coatings, epoxy resin coatings, radiation-absorbing coatings, etc., can solve the problems of blocking infrared energy, limited infrared blocking bandwidth, complex processing procedures and processes, and achieve high infrared Light blocking rate, high visible light transmittance, and remarkable thermal insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] The preparation of nano-coating 1 is prepared by mixing commercially available nano-dispersion liquid A: 6 parts, nano-dispersion liquid B: 1 part, butanone: 7.5 parts, photocurable resin mixture: 6.5 parts, and stirring evenly at room temperature. Nano Coating 1.

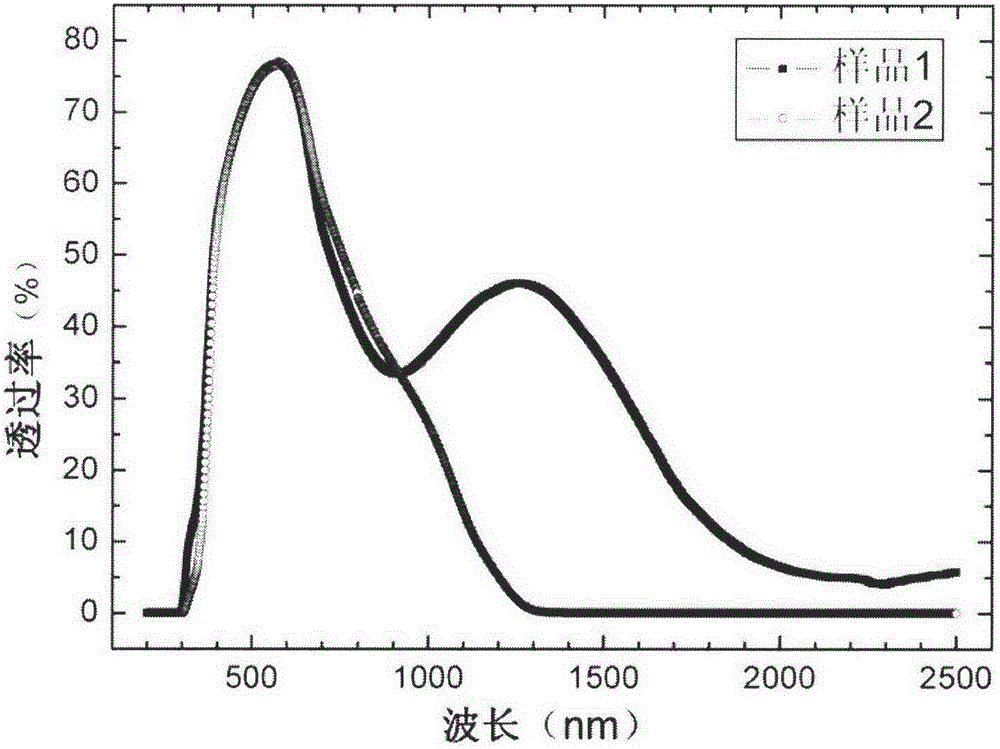

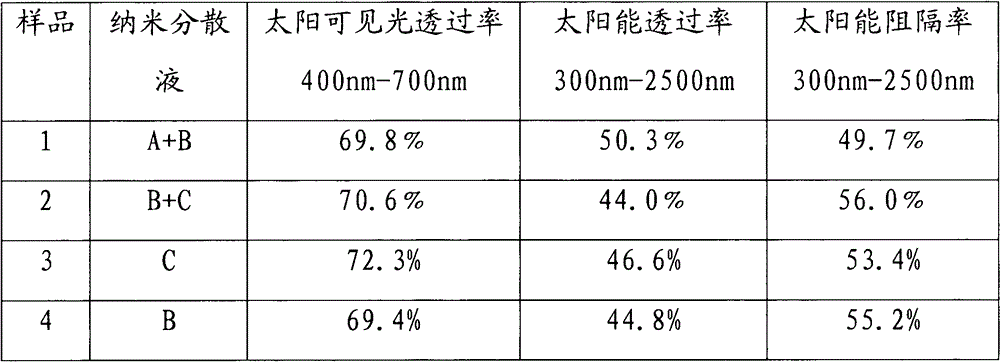

[0039] The specific characteristics of the nano-coating can be tested by preparing the nano-coating 1 into a nano-film, as follows: Coat the nano-coating 1 on a glass substrate with a thickness of 1 mm with a wire bar coater, and bake it in an oven at 70 degrees for 1 minute , and finally cured under the ultraviolet light mercury lamp to prepare sample 1 of the nano-film, its transmittance in the ultraviolet, visible and infrared bands is shown in figure 1 , the visible light transmittance and solar energy blocking rate of the sample under sunlight are 69.8% and 49.7% respectively (see Table 1 and figure 1 ).

Embodiment 2

[0041] For the preparation of nano-coating 2, mix commercially available nano-dispersion liquid B: 0.8 parts, nano-dispersion liquid C: 3 parts, methyl isobutyl ketone: 10.9 parts, photocurable resin mixture: 6.5 parts, and stir evenly at room temperature. Nano-coating 2 can be prepared.

[0042] The sample 2 of nano-coating 2 and nano-membrane prepared identically with the method described in embodiment 1, its transmittance in ultraviolet, visible light and infrared band see figure 1 , the visible light transmittance and solar energy blocking rate of this sample under sunlight are 70.6% and 56% respectively (see Table 1 and figure 1 ).

Embodiment 3

[0044] Nano-coating 3 was prepared by mixing commercially available nano-dispersion liquid C: 6 parts, methyl isobutyl ketone: 10.2 parts, photocurable resin mixture: 6.5 parts, and stirring evenly at room temperature to prepare nano-coating 3.

[0045] The nano-coating 3 and sample 3 of the nano-film prepared in the same way as in Example 1 have visible light transmittance and solar energy blocking rate under sunlight of 72.3% and 53.4% respectively (see Table 1).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com