Method for producing microbial flocculant by utilizing culture wastewater and residual activated sludge

A technology for microbial flocculants and aquaculture wastewater, which is applied in the field of wastewater treatment and disposal, can solve the problems of low output of biological flocculants, reduced dosage of flocculants, and large amount of additional carbon sources, so as to achieve comprehensive utilization of waste and no secondary environmental pollution. , the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

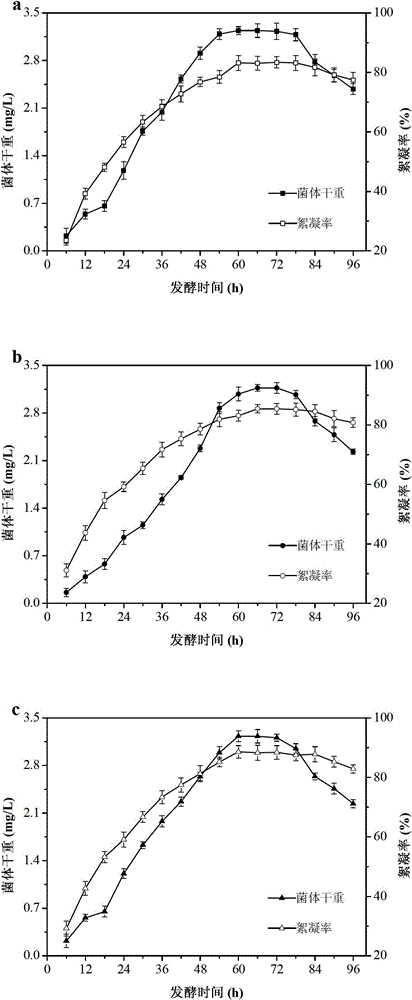

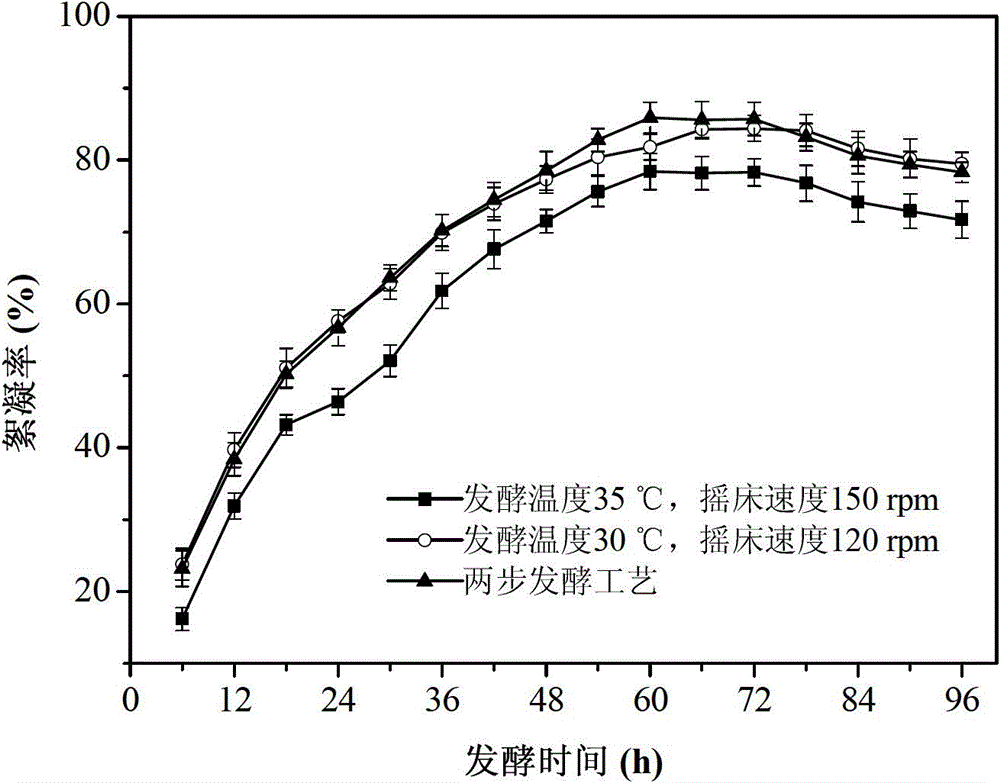

[0020] Implementation example 1 Production of microbial flocculant by using a two-step fermentation process using aquaculture wastewater

[0021] 1. Production of microbial flocculants

[0022] Pick a few colonies from the fresh Rhodococcus erythropolis slant preservation medium into a 250ml shake flask containing 150ml of seed medium, and culture them at 30°C and 120rpm for 24h. This seed solution is used as the inoculation solution when producing flocculants. Preparation of fermentation medium: 1.0L of breeding wastewater; 10g of sucrose; KH 2 PO 4 2.0g; K 2 HPO 4 5.0g; NaCl 1.0g; MgSO 4 0.2g; the initial pH of the fermentation medium was 8.0. The seed solution was inoculated into the fermentation medium at an inoculation amount of 2% (v / v). In the initial 24 hours of fermentation, the fermentation conditions of fermentation temperature 35°C and shaker speed 150rpm were adopted to shorten the stagnation period of bacterial growth, so that the bacterial concentratio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com