Solid-state heat storage structure and processing method

A processing method and heat storage technology, which is applied in the field of heat storage devices in solar thermal utilization systems, can solve problems such as high cost, toxicity of inorganic salts, and high solidification temperature, and achieve enhanced heat transfer, good thermal conductivity, and enhanced The effect of heat transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with embodiments.

[0026] Aggregate in highway engineering refers to the solid particles that play the role of skeleton and filling in the mixture, including crushed stone, gravel, machine-made sand, stone chips, sand, metal chips, slag, etc. Gradation refers to the distribution of aggregate particles at various levels, which can be determined by sieve analysis. Grading is also a concept of highway implementation. The required porosity and surface area are obtained by selecting different aggregates and using different ratios.

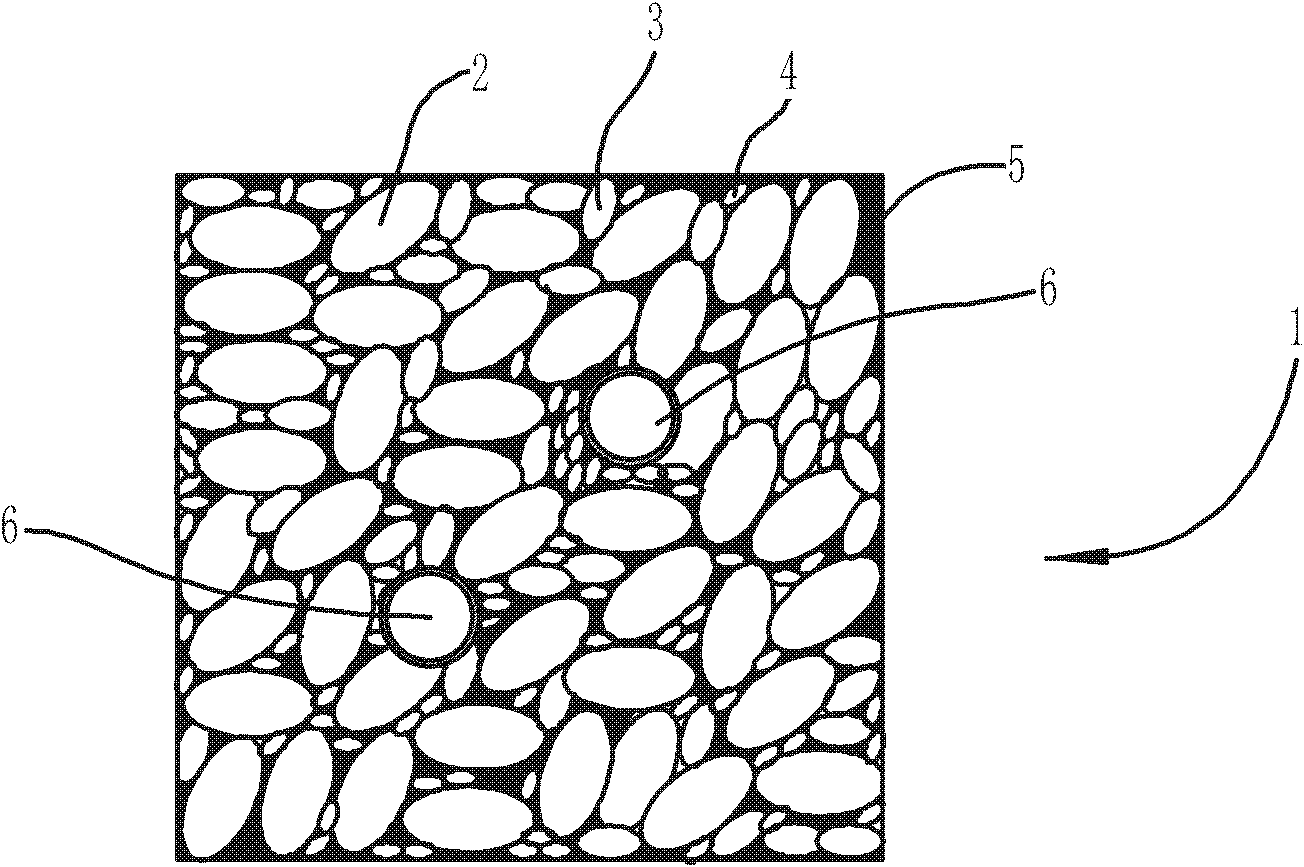

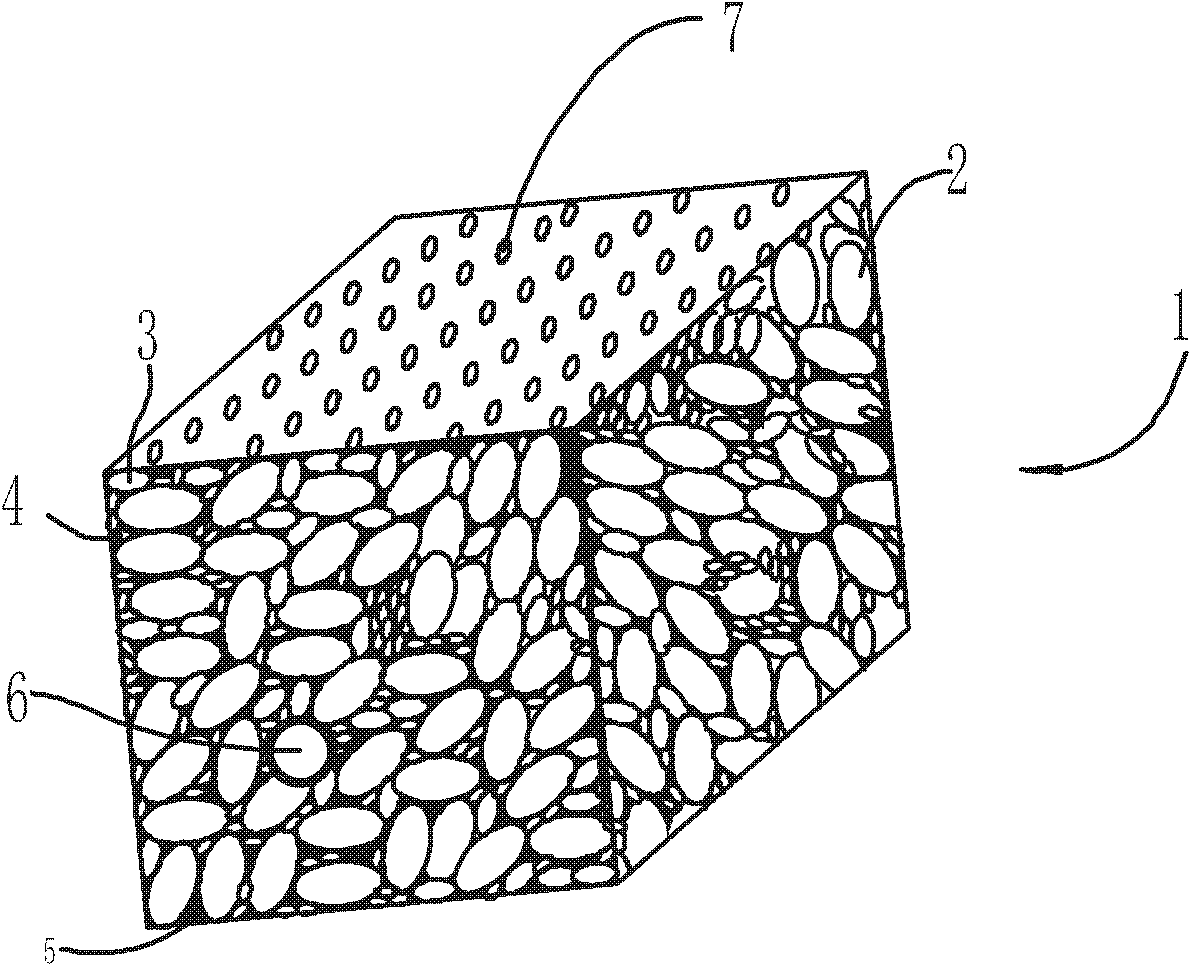

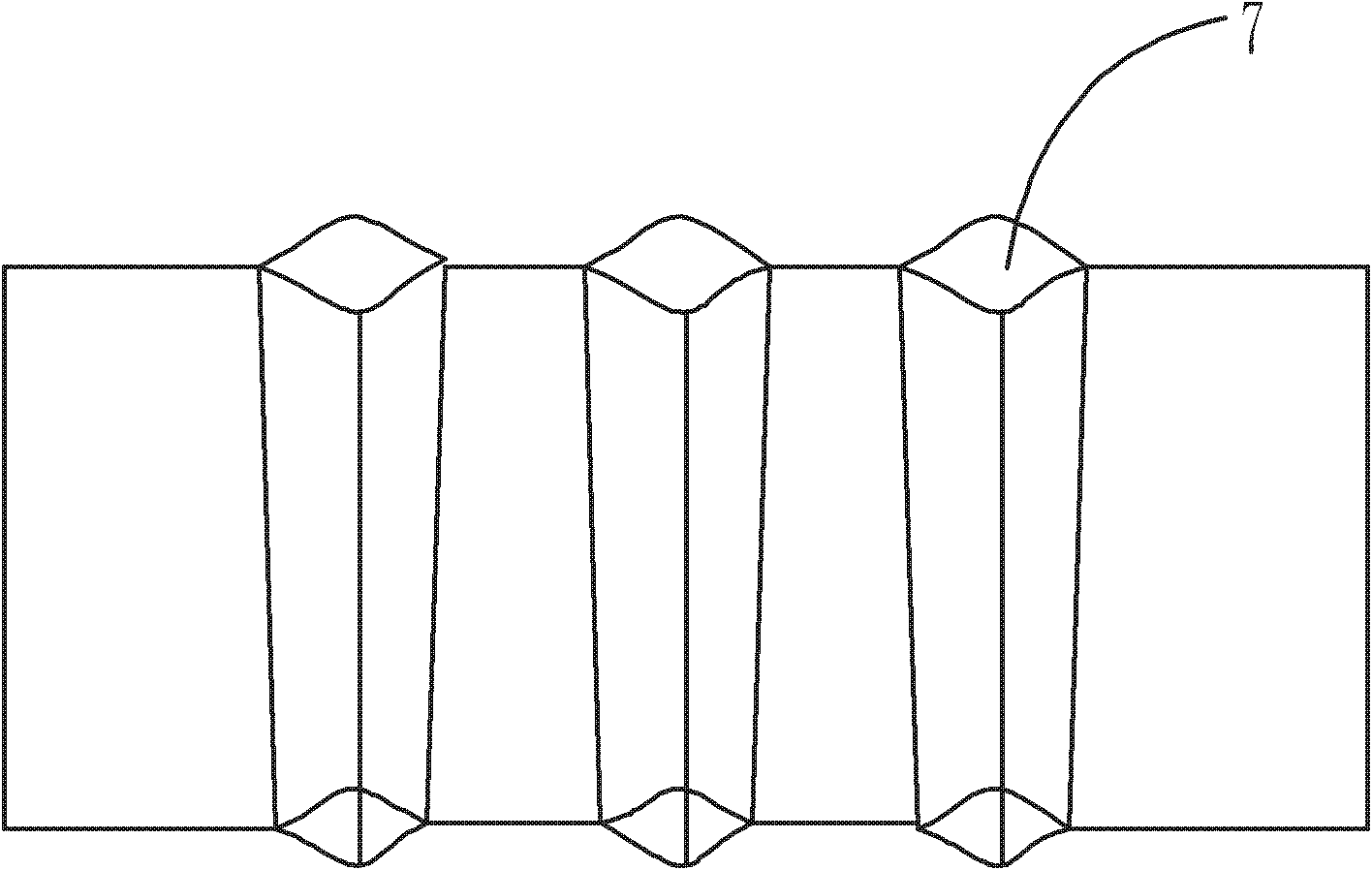

[0027] figure 1 It is a schematic diagram of the first embodiment of the overall structure of the solid heat storage block of the present invention. The solid heat storage structure 1 of the first embodiment is composed of a mixture of multiple mixtures, that is, a high thermal conductivity heat storage solid heat storage structure 1 integrally formed by coarse aggregate ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com