Grouting material

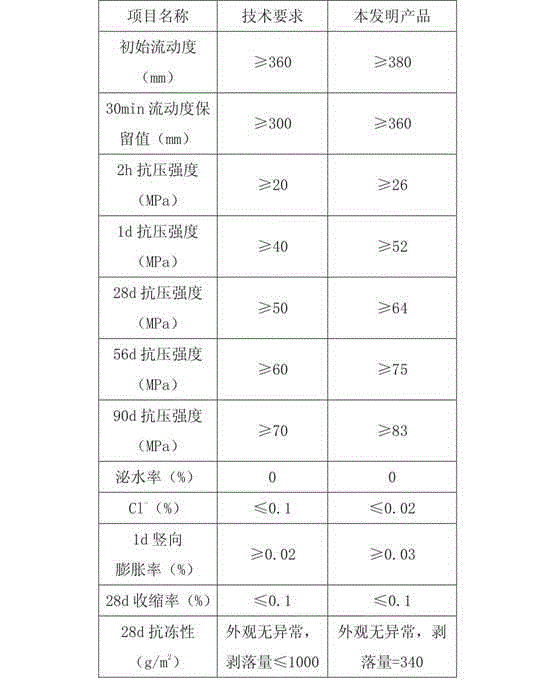

A grouting material and strength grade technology, applied in the field of non-shrinkage grouting materials and engineering materials, can solve the problems of unable to guarantee the retention value of later fluidity, unable to obtain high initial fluidity, unable to obtain high early strength, etc. Convenient and fast, good fatigue resistance, high early strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Weighing: 400kg of sulphoaluminate cement with a strength grade greater than or equal to 42.5, 50kg of ordinary Portland cement with a strength grade of greater than or equal to 42.5, 50kg of granulated blast furnace slag powder, 30kg of gypsum powder, 50kg of sodium aluminate, powder Coal ash 100kg, heavy calcium powder 20kg, ceramsite with a particle size of 0.25-0.35mm 40kg, ceramsite with a particle size of 0.35-0.50mm 60kg, ceramsite with a particle size of 0.50-2.00mm 100kg, fineness modulus 0.8 100kg of river sand, 5kg of hydroxypropyl methylcellulose, 5kg of UEA expansion agent, Na 2 Naphthalene-based water reducer with SO4 content less than 3% 3kg, sulfamate water reducer 3kg, polycarboxylate water reducer 3kg, citric acid 0.2kg, boric acid 0.2kg, sodium gluconate 0.2kg, sodium phosphate 0.2kg, Sodium tartrate 0.2kg, calcium carbonate 0.2kg, lithium carbonate 0.2kg, calcium formate 0.2kg, calcium acetate 0.2kg, polydimethylsiloxane 0.5kg, polyoxyethylene polyox...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com