Wood-plastic material with distiller's grain as reinforcing phase, and manufacturing method thereof

A technology of wood-plastic material and reinforcement phase, which is applied in the field of new materials, can solve problems such as the production of wood-plastic materials that have not yet been seen, and achieve the effects of reducing white pollution, solving environmental pollution, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

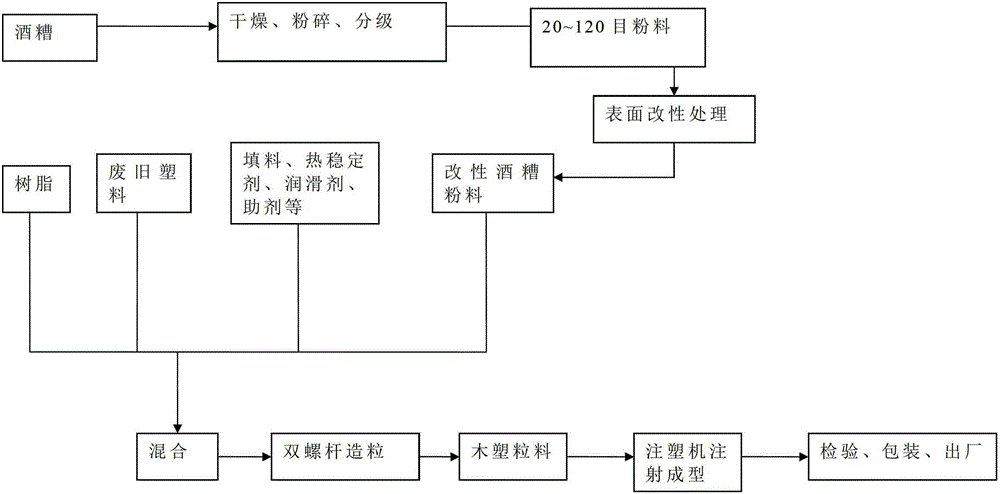

[0035] Preparation of wood-plastic samples by injection molding process:

[0036]

[0037] Prepare wood-plastic samples by injection molding process according to the above formula. The specific process is: first obtain masterbatch by twin-screw extruder (temperature 160°C), and then obtain splines by injection molding by injection molding machine (injection pressure 60MPa, speed 60cm3 / s , the holding time is 4s at 40MPa, 4s at 30MPa, 3s at 20MPa, and the cooling time is 25s).

[0038] The wood-plastic board prepared by this process has good appearance and processing performance, and has high mechanical strength after testing, with a tensile strength of 15MPa, a bending strength of 30MPa, and an impact strength of 20KJ / m2.

example 2

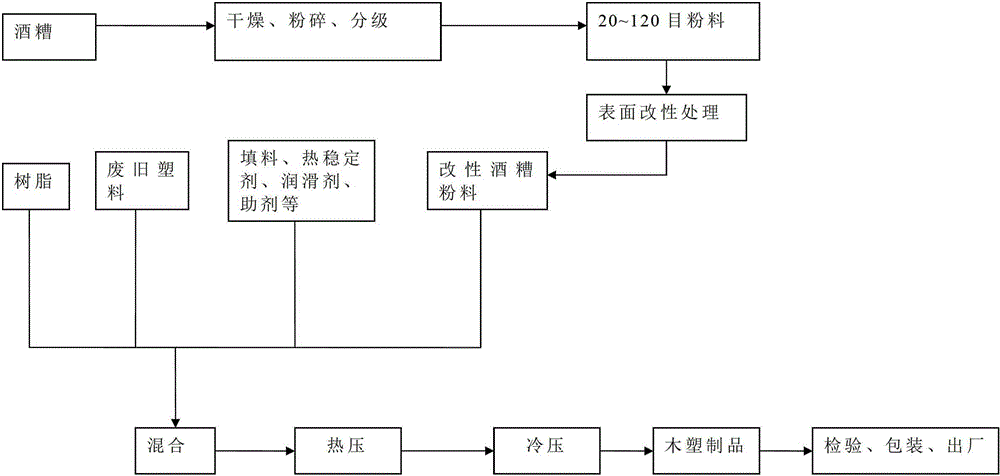

[0040] Preparation of wood-plastic samples by compression molding process:

[0041]

[0042] Distiller's grains powder, HDPE, maleic anhydride grafted PE, polyethylene wax, and zinc stearate are fully mixed in proportion, put into a mold, and placed on a flat vulcanizer for molding. The molding process is as follows: image 3 , wherein the hot pressing is 5min, the temperature is 160°C, the pressure is 5MPa, the cold pressing is 10min, and the pressure is 10MPa.

[0043] The obtained wood-plastic product has good appearance and processing performance, and has high mechanical strength after testing, with a tensile strength of 10MPa, a bending strength of 23MPa and an impact strength of 5MPa.

example 3

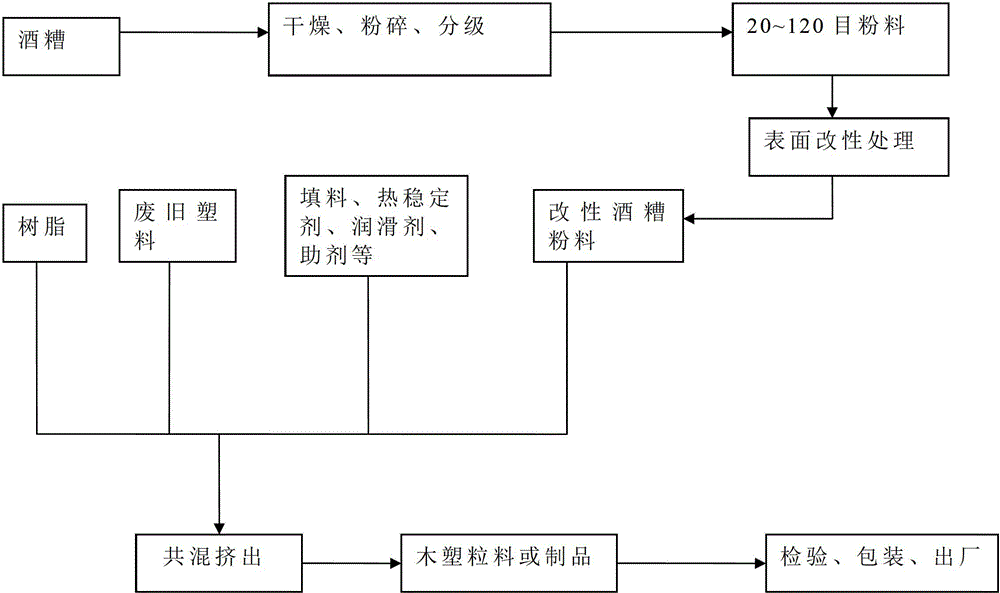

[0045] Extrude WPC pellets or directly extrude WPC

[0046]

[0047] The modifier is selected from maleic anhydride or its grafted PP, PE, polybutadiene, poly1,4 butadiene, acrylonitrile, methyl methacrylate, styrene, and the distiller's grain powder is mixed with the modifier Heat to about 70°C, stir evenly, and then mix with other materials and extrude through an extruder. The coupling agent is selected from one or more of aluminate, titanate, and silane coupling agents. The auxiliary agent is selected One or more of ultraviolet absorbers, plasticizers, lubricants, heat stabilizers, antifungal agents, antioxidants, foaming agents, colorants, antibacterial agents, and flame retardants.

[0048] According to the performance requirements of the product, the addition amount of each component of the above formula is different. Mix the processed distiller's grains powder with other components evenly, and then extrude the wood-plastic products from the extruder through twin-scre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

| Impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com