Production method for synthesizing acetic acid through carbonylation

A production method and a chemical synthesis technology are applied in the production field of oxo-synthesizing acetic acid, which can solve the problems of high rhodium concentration, high energy consumption for propionic acid separation, and high propionic acid impurity concentration, so as to improve the utilization rate of CO and reduce the water-gas reaction , the effect of increasing the reaction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

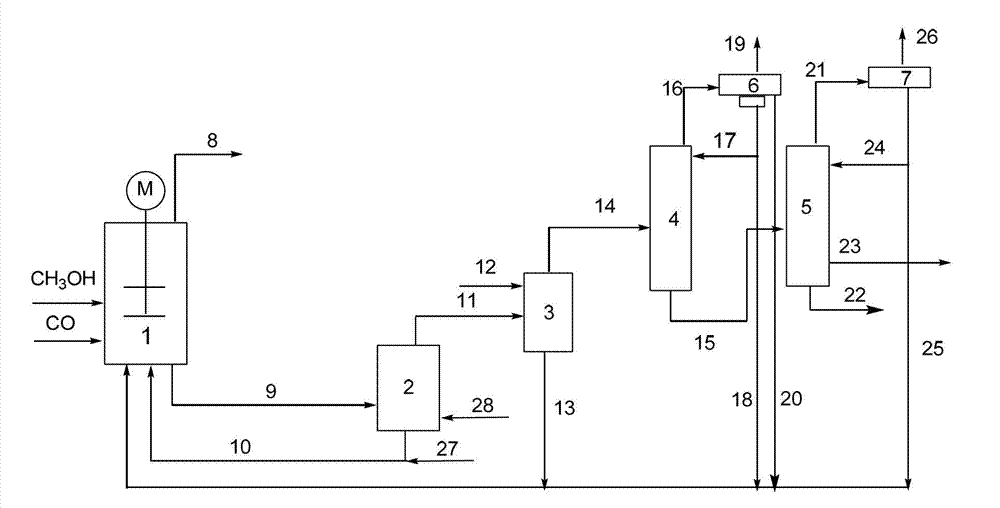

Method used

Image

Examples

Embodiment 1

[0045] The rhodium acetate, ruthenium acetate, methyl iodide, distilled water, methyl acetate, lithium iodide and sodium iodide of one-time charge into the zirconium material autoclave that pressure gauge is housed in 200ml make the rhodium concentration in the reaction system be 700ppm, The concentration of ruthenium is 600ppm, the concentration of sodium is 50ppm, methyl iodide is 12%, distilled water is 6%, methyl acetate is 20%, lithium iodide is 6%, and the rest is acetic acid solvent. Keep the reaction temperature at 190°C and the reaction pressure at 30bar. STY is 8.6mol / l.h. At 3% ester concentration, the average STY of acetic acid at 1.2% water content was 5.8 mol / l.h. After the reaction, the content of by-product propionic acid was determined to be 250 ppm. After the reaction, the water-containing 1.0% liquid is protected with a mixed gas containing hydrogen, which is a mixed gas of nitrogen and hydrogen. The chromatographic analysis shows that the hydrogen content ...

Embodiment 2

[0047] The rhodium acetate, ruthenium acetate, methyl iodide, distilled water, methyl acetate, lithium iodide and potassium iodide of metered rhodium acetate, ruthenium acetate, lithium iodide and potassium iodide are loaded into once in the zirconium material autoclave that pressure gauge is housed in 200ml, so that rhodium concentration is 700ppm in the reaction system, ruthenium The concentration is 1200ppm, the potassium concentration is 200ppm, 12% methyl iodide, 6% distilled water, 20% methyl acetate, 6% lithium iodide, and the rest is acetic acid solvent. Keep the reaction temperature at 190°C and the reaction pressure at 30bar. It is 8.75mol / l.h. At 3% ester concentration, the average STY of acetic acid at 1.7% water content is 6.0mol / l.h. After the reaction, the content of by-product propionic acid was determined to be 270 ppm. After the reaction, the liquid containing 1.5% water was protected with a mixed gas containing hydrogen. The mixed gas was a mixed gas of nit...

Embodiment 3

[0049] Rhodium iodide, ruthenium acetate, methyl iodide, distilled water, methyl acetate and lithium iodide are loaded into a 200ml zirconium material autoclave with a pressure gauge at one time, so that the rhodium concentration in the reaction system is 700ppm, and the ruthenium concentration 1800ppm, 12% methyl iodide, 6% distilled water, 20% methyl acetate, 6% lithium iodide, and the rest is acetic acid solvent. Keep the reaction temperature at 190°C and the reaction pressure at 30bar. The average STY of the acetic acid reacted is 8.5mol / l.h. At 3% ester concentration, the average STY of acetic acid at 1.2% water content was 6.7mol / l.h. After the reaction, the content of by-product propionic acid was determined to be 240 ppm. After the reaction, the reaction solution containing 1.0% water was protected with a mixed gas containing hydrogen. The mixed gas was a mixed gas of nitrogen and hydrogen. The chromatographic analysis showed that the hydrogen content was 3% vol. Under...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com