Benthiavalicarb-isopropyl emulsion in water and preparation method thereof

A technology of benthiafen and water emulsion is applied in the field of water emulsion of benthiafen and preparation thereof, can solve problems such as harm to health, high manufacturing cost, environmental pollution, etc., achieves less environmental pollution, reduced production cost, The effect of reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

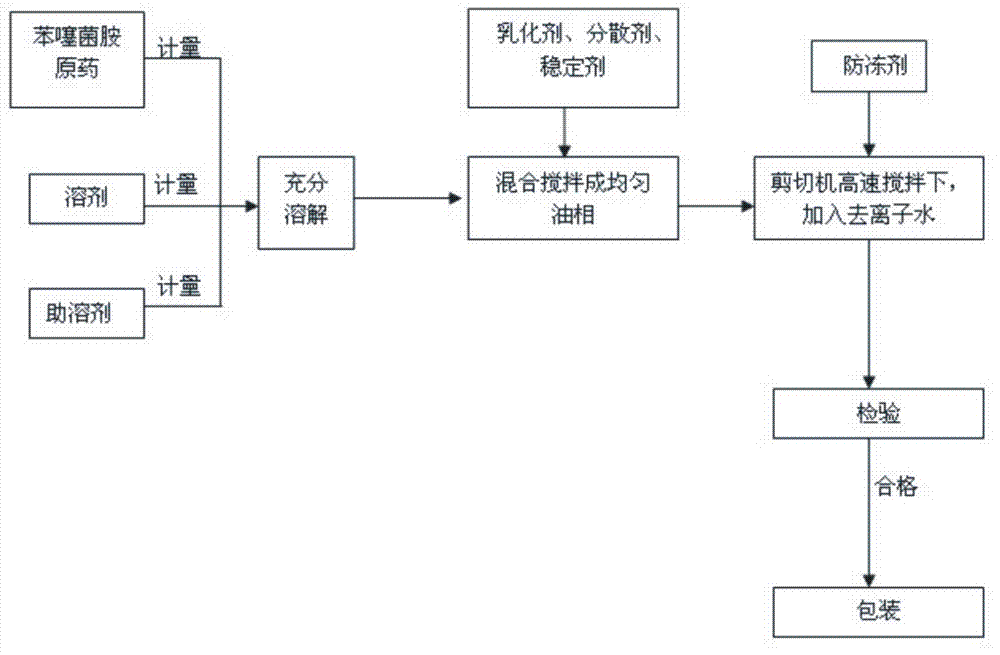

Method used

Image

Examples

Embodiment 1

[0021] Example 1: benthiazil 5%, xylene alcohol 12%, the two are mixed, fully dissolved to obtain the oil phase; castor oil polyoxyethylene ether 3%, fatty alcohol polyoxyethylene ether 2%, alkylphenol formaldehyde resin 1% polyoxyethylene ether sulfate, 2% pyrogallic acid, 2% peanut oil and 4% ethylene glycol, put them into deionized water together, stir fully in the preparation kettle to make a water phase, turn on the stirring and put the oil phase was slowly added to the water phase, and sheared at 6000 rpm for 30 minutes to obtain a 5% benthiazil emulsion in water.

Embodiment 2

[0022] Example 2: 10% benthiazil, 10% xylene, and 10% diethyl phthalate, the three are mixed and fully dissolved to obtain an oil phase; polyoxyethylene sorbitan fatty acid ketone 2%, polyol 1.5% fatty acid ester and its ethylene oxide adduct, 1% sodium dioctyl maleate sulfonate, 2% antioxidant 264, 4.0g peanut oil and 4% glycerol, put together In deionized water, fully stir in the preparation kettle to make the water phase, turn on the stirring, slowly add the oil phase to the water phase, cut at 6000 rpm for 15 minutes, and prepare 10% benthiazil water emulsion.

Embodiment 3

[0023] Example 3: benthiazil 20%, N-octylpyrrolidone 10%, aromatic hydrocarbon solvent Solvesso150 25%, the three are mixed, fully dissolved to obtain an oil phase; castor oil polyoxyethylene ether 4%, polyoxyethylene dehydration Sorbitol fatty acid ketone 2%, fatty alcohol polyoxyethylene ether 1%, alkylphenol formaldehyde resin polyoxyethylene ether sulfate 1%, epoxy soybean oil 5% and glycerol 4%, after fully stirring in the preparation kettle Prepare the water phase, turn on the stirring, slowly add the oil phase into the water phase, cut at 6000 rpm for 20 minutes, and prepare 20% benthiazil emulsion in water.

[0024] The benthiazil aqueous emulsion of the present invention overcomes the shortcomings of traditional formulations such as emulsifiable concentrates and powders, and has the advantages of environmental protection and low use cost. During processing and use, the pollution to the environment is reduced, and the use cost of farmers is reduced. . Field efficacy t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com