Preparation method of molecular engram composite film for separating tryptophane isomer

A technology of molecular imprinting and tryptophan, which is applied in the direction of semipermeable membrane separation, chemical instruments and methods, membrane technology, etc., can solve the problems of binding stability and poor compatibility between basement membrane and functional base, and achieve separation effect Significant, fast separation speed, and simplified operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

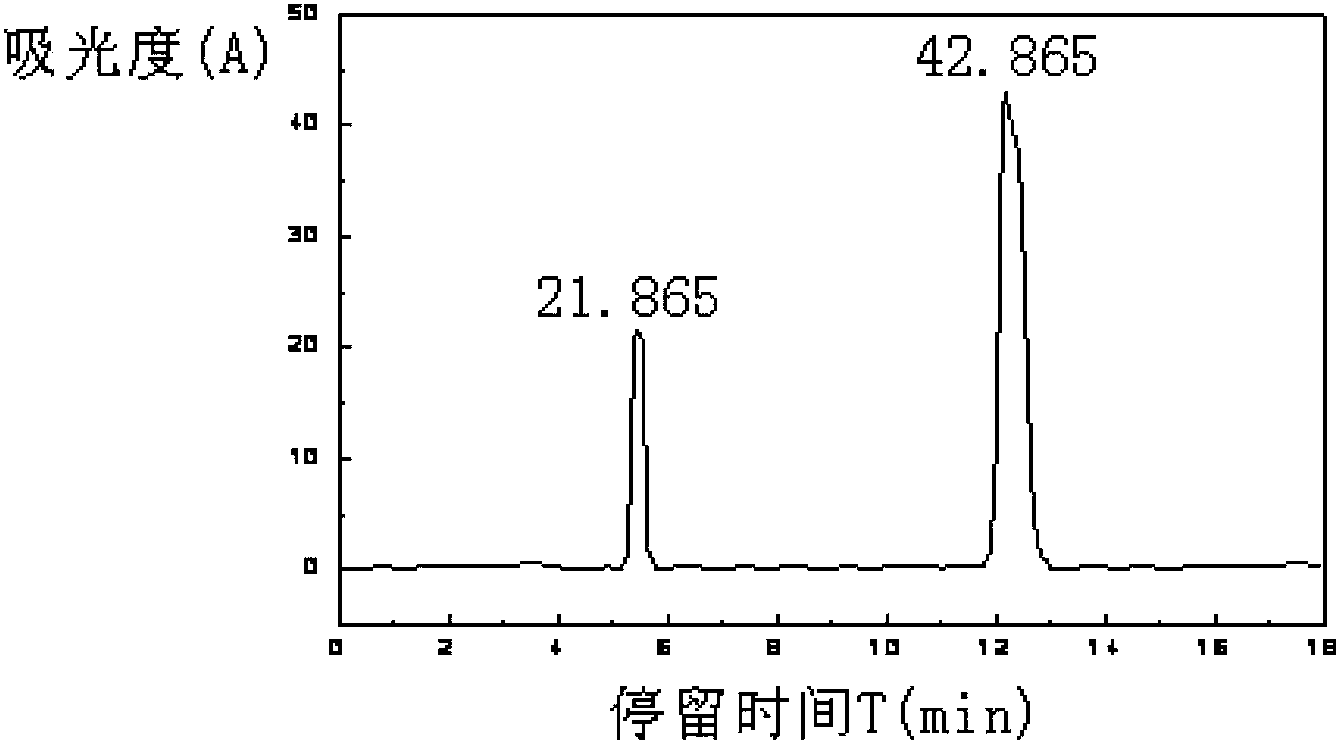

Embodiment 1

[0036] Step 1, preparing polyvinylidene fluoride (PVDF) / polyvinyl alcohol (PVA) blended ultrafiltration base membrane:

[0037] (1) Preparation of casting solution: mix 20 parts by mass of PVDF / PVA mixed resin material (the mass ratio of PVDF to PVA is 4 / 1, the molecular weight range of PVDF is 400~600KDa, and the molecular weight range of PVA is 30~15KDa , and the hydroxyl hydrolysis degree of PVA ≥ 98%) and 3 parts by mass of anhydrous lithium chloride were added to 77 parts by mass of dimethylformamide, mixed at 90°C and placed for 12 hours to obtain a casting solution;

[0038] (2) Preparation of nascent basement membrane: Pour the casting liquid onto a flat and clean glass plate, and scrape the nascent basement membrane with a uniform and smooth round rod-shaped steel member with 0.3mm copper wires fixed on both sides;

[0039] (3) Gel phase separation: After the nascent basement membrane stays in the air for 30s, it is immersed in deionized water at 40°C to form a gel ph...

Embodiment 2

[0050] The difference from Example 1 is that vinylidene fluoride and polyvinyl alcohol resin material (wherein PVDF / PVA=6 / 1 (mass ratio) with mass parts of 16, and lithium chloride with mass parts of 5, and The organic solvent dimethylformamide with a mass fraction of 68 was blended and dissolved to prepare a PVDF / PVA blended ultrafiltration membrane with a pure water flux of 128L / h m 2 , BSA retention rate is 99.5%.

[0051] Using 2% (v / v) acetic acid aqueous solution as solvent, prepare chitosan 3% (w / w), D-tryptophan 0.75% (w / w), glutaraldehyde 0.3% (w / w) For the coating solution, adjust the pH to 2 with hydrochloric acid, and pour the coating solution into a tetrafluoroethylene dish covered with a polyvinylidene fluoride / polyvinyl alcohol (PVDF / PVA) blended base film at the bottom to soak the film surface by about 0.2 mm, after standing at room temperature for defoaming, put the film in an oven at 50°C until the film is basically dry. After removing the film, rinse the re...

Embodiment 3

[0054] The conditions of the base film in this example are the same as in Example 1. The concentration of chitosan in the coating solution is 5% (w / w), the template L-tryptophan is 1.25% (w / w), the concentration of glutaraldehyde is 0.2% (w / w), pH=2, membrane preparation And elution method is with example 1.

[0055] Under the same osmotic conditions as in Example 1, the osmotic separation factor of the obtained chitosan molecularly imprinted composite membrane was 2.21.

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com