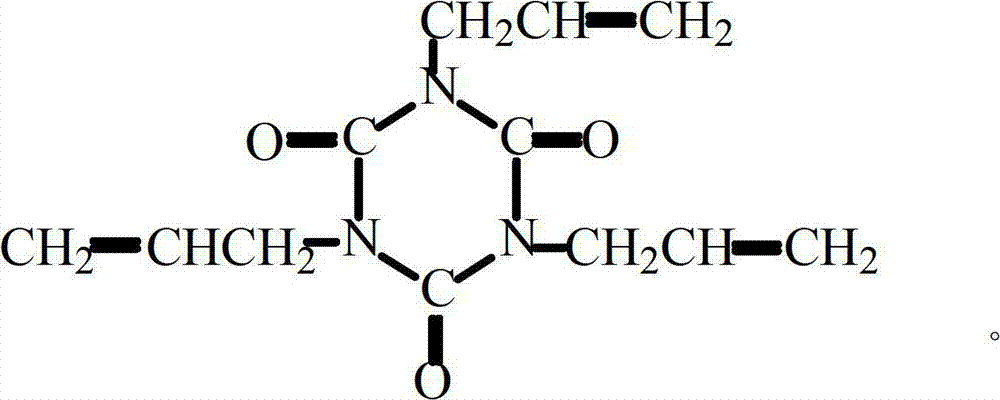

Preparation method of cross linking agent triallyl isocyanurate

A technology of triallyl isocyanurate and cross-linking agent, applied in the direction of organic chemistry, etc., can solve the problems of increased production cost, harmful salt-containing wastewater of biochemical pool microorganisms, etc., and achieves reduction of energy consumption or equipment investment cost, Significant environmental protection and economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

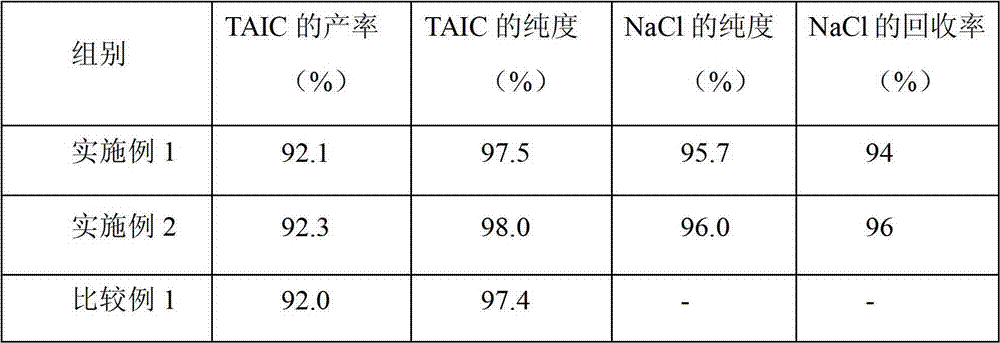

Embodiment 1

[0031] In a 500L stainless steel reaction kettle equipped with a thermometer, stirrer and reflux condenser, add 184kg of dimethylformamide (DMF), 1.8kg of calcium chloride, 88kg of sodium cyanate (content 95%), and 1.4kg of triethylamine , heated to 110°C under stirring, slowly added 96.0kg of chloropropene (content 98%) into the reaction kettle dropwise within 3 hours, after adding chloropropene, 1.5kg of sodium chloride crystals and 1.5kg of tetrabutyl chloride The amine was added into the reaction kettle, and the stirring reaction was continued at 120°C for 3 hours, and the temperature was lowered to room temperature after the reaction was completed. The sodium chloride solid in the reaction liquid is separated by pressure filtration, and the sodium chloride filter cake is rinsed with fresh or recycled DMF40kg, and the washing liquid is incorporated into the filtrate to obtain a mixed solution. Sodium chloride is dried through vacuum drier and reclaims DMF solvent simultane...

Embodiment 2

[0034] Add 190kg DMF, 2.0kg calcium chloride, 88kg sodium cyanate (content 95%), 1.0kg potassium bromide into a 500L stainless steel reaction kettle equipped with a thermometer, agitator and reflux condenser, and heat to 115°C under stirring , 96.0kg of allyl chloride (content 98%) was added dropwise to the reactor within 3 hours. After the addition of allyl chloride, 2.0kg of sodium chloride crystals and 2.0kg of benzyltriethylammonium chloride were added to the reactor. The stirring reaction was continued at 130° C. for 3 hours, and the temperature was lowered to room temperature after the reaction was completed. The sodium chloride solid in the reaction solution was separated by pressure filtration, washed once with 40 kg of fresh DMF, and the washing solution was incorporated into the filtrate to obtain a mixed solution. The filter cake was dried to obtain 74.0kg of sodium chloride by-product with a white appearance, a content of 96.0%, and a recovery rate of 96% of sodium...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com