Preparation method of injectable double-cross-linked hydrogel for tissue engineering

A tissue engineering and injectable technology, applied in the field of preparation of injectable double-cross-linked hydrogel, achieves the effects of good biological inertness, simple operation process and strong mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

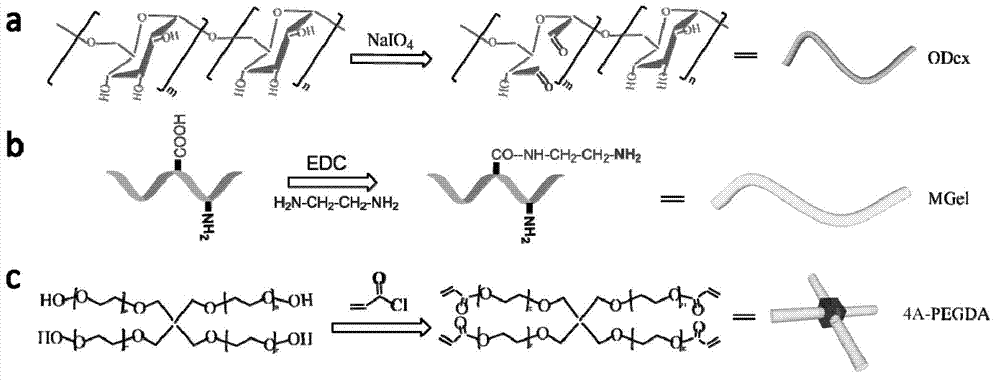

[0035] Such as figure 1 As shown in a, add dextran into deionized water, stir magnetically until the dextran is completely dissolved, and make an aqueous solution of dextran with a concentration of 1% by mass. Add sodium periodate (NaIO 4 ), wherein the molar ratio of sodium periodate to the structural unit of dextran was 1:2, and the reaction was stirred in the dark at room temperature (25°C) for 4 hours, then 5ml of ethylene glycol was added, and the stirring was continued for 15 minutes to terminate the reaction. The product was put into a dialysis bag (molecular weight cut-off: 3500) for dialysis for 3 days, and the water was changed 4 times a day. Then the product was taken out and placed in a plastic petri dish, pre-frozen in a low-temperature refrigerator for 12 hours, and the pre-frozen product was freeze-dried to finally obtain a white product of partially aldylated dextran.

Embodiment 2

[0037] Such as figure 1 As shown in b, take gelatin and dissolve it in 0.1M phosphate solution (pH 5.0) to obtain a gelatin aqueous solution with a mass percent concentration of 4%. After it is completely dissolved (the solution is a transparent liquid), add ethylenediamine (ED). Mix evenly with magnetic stirring, adjust to pH=5.0 with 6M HCl, then add carbodiimide (EDC), and react at room temperature for 4 hours; wherein the molar ratio of carboxyl, ethylenediamine and carbodiimide on the gelatin is 1: 40:2. Put the product into a dialysis bag (cut off Mw=3500) and dialyze for 3 days, changing the water 3~4 times a day. After the dialysis is complete, the dialysate is poured into a plastic watch glass, placed in a low-temperature refrigerator for pre-freezing for 24 hours, and the pre-frozen material is freeze-dried to finally obtain a white product of modified gelatin.

Embodiment 3

[0039] Such as figure 1 As shown in c, take 8g of four-walled polyethylene glycol and dissolve it in 200ml of anhydrous dichloromethane, remove a small amount of water in the four-walled polyethylene glycol by azeotropic distillation, cool to room temperature, add triethylamine, and then Acryloyl chloride was added dropwise under the protection of nitrogen, and reacted for 48 hours at room temperature, wherein the molar ratio of four-walled polyethylene glycol, triethylamine and acryloyl chloride was 1:4:8. After that, it was purified by precipitation with excess ether, dissolved again in dichloromethane, precipitated with excess ether, the purification process was repeated three times, and dried under reduced pressure at room temperature to obtain a white product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compression modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com