Methyl-p-hydroxy benzoate surface imprinting absorbent as well as preparation method and application thereof

A methylparaben, surface imprinting technology, applied in chemical instruments and methods, non-metallic elements, other chemical processes, etc., can solve problems such as skin and mucous membrane inflammation, epidermal cell destruction, gastrointestinal discomfort, etc., and achieve high adsorption capacity. , reducing non-specific adsorption, high selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] (1) Synthesis of monodisperse silica nanoparticles

[0043] Add 4.45 mL tetraethyl orthosilicate (TEOS), 9.0 mL H 2 O, 48.95 mL of ammonia water with a concentration of 7.0 mol / L, and 37.6 mL of absolute ethanol were stirred at room temperature (25°C) for 4 to 5 hours; the reaction product was washed with distilled water until neutral, and dried under vacuum at 60°C.

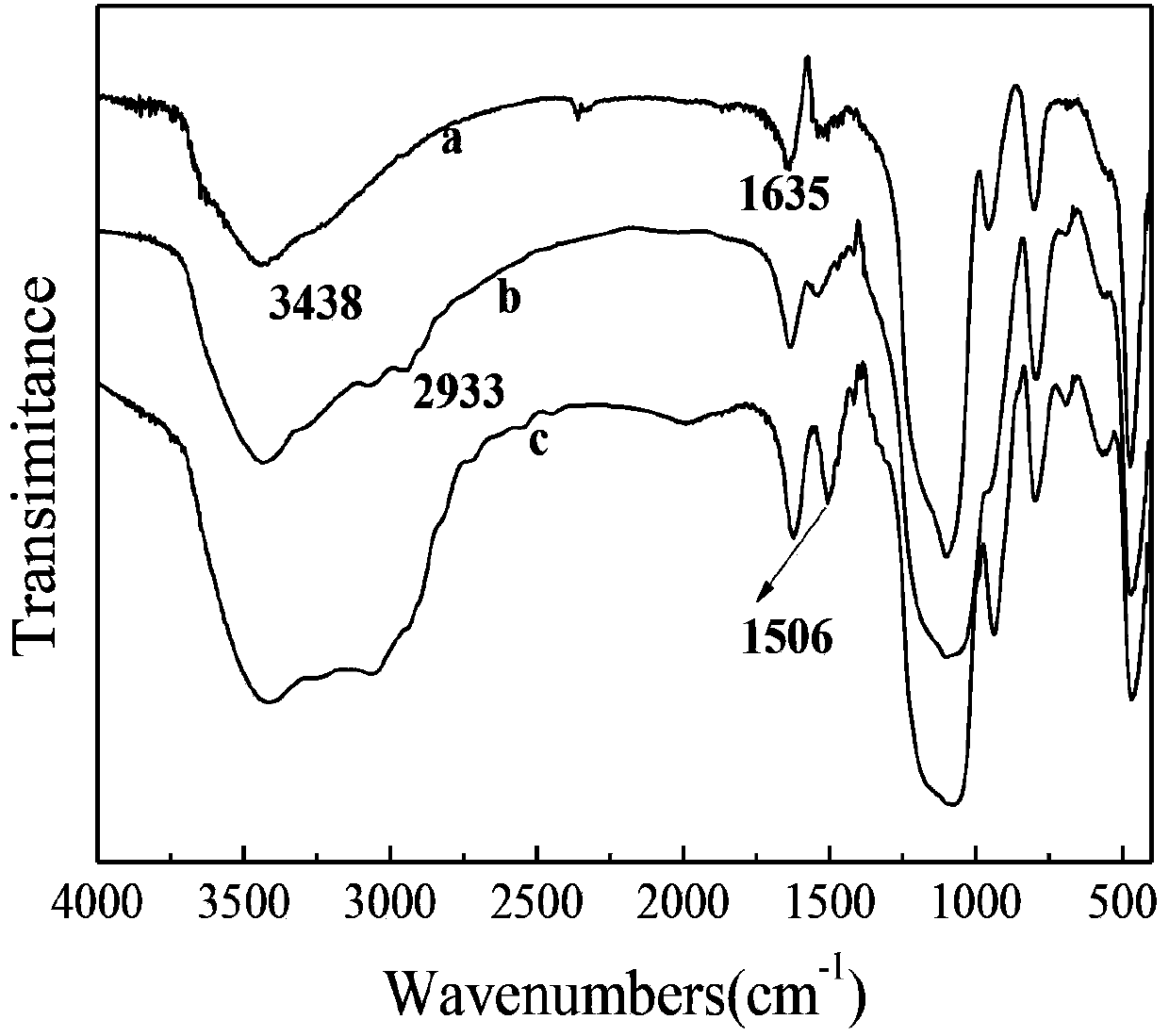

[0044] (2) Methylparaben imprinted polymer (MIP MP ) preparation

[0045]200 mg of monodisperse silica nanoparticles were added to 15 mL of methanol for ultrasonic dispersion for 5 min, followed by 1.0 mmol of methylparaben (MP), 5 mmol of 3-aminopropyltriethoxysilane (APTES ), added to the above suspension to make the template molecules react with functional monomers to form a pre-assembled system, then add 2.0 mL tetraethyl orthosilicate (TEOS) and 0.5 mL 1mol / L acetic acid to the suspension, Stir at room temperature (25°C) for 24 h; then centrifuge and dry under vacuum at 60°C for 12 h; the synthesi...

Embodiment 2

[0053] (1) Synthesis of silica nanoparticles

[0054] Add 4.05 mL tetraethyl orthosilicate (TEOS), 9.0 mL H 2 O, 48.95 mL of ammonia water with a concentration of 7.0 mol / L, 38.0 mL of absolute ethanol, stirred at room temperature (25 °C) for 4 to 5 hours; the reaction product was washed with distilled water until neutral, and dried under vacuum at 60 °C.

[0055] (2) Methylparaben imprinted polymer (MIP MP ) preparation

[0056] Add 400 mg of monodisperse silica nanoparticles into 30 mL of methanol and ultrasonically disperse for 5 min, then add 2.0 mmol of methylparaben (MP), 10 mmol of 3-aminopropyltriethoxysilane (APTES ), added to the above suspension to make template molecules react with functional monomers to form a pre-assembled system, then add 4 mL tetraethyl orthosilicate (TEOS) to the above mixture, 1 mL 1mol / L acetic acid in the suspension, Stir at room temperature for 18 h; then centrifuge and dry in vacuum at 60 °C for 16 h; the synthesized polymer was washed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

| volume | aaaaa | aaaaa |

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com