Coal briquette composite crosslinking binder and production method thereof

A production method and composite technology are applied in the field of briquette binder, which can solve the problems of low water absorption rate of the binder, difficulty in production and use, inability to continuous production, etc., and achieve good formability, good appearance, and no clogging of slag discharge. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

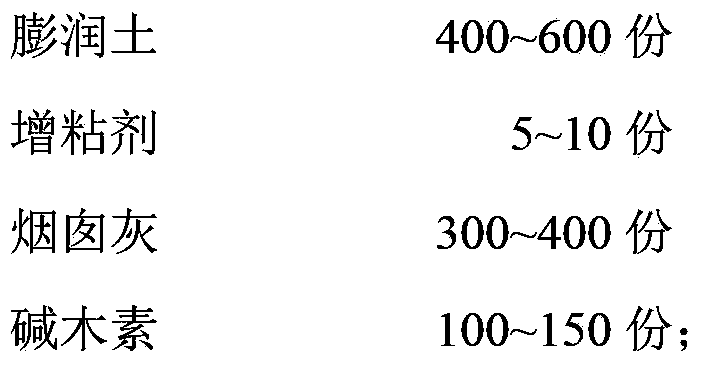

[0060] A briquette composite crosslinking binder, its raw material composition is as follows:

[0061]

[0062] Wherein, the weight ratio of each component in the tackifier is:

[0063]

[0064] The chimney ash in this embodiment is selected from the chimney and / or dust removal equipment of a chemical plant, with a calorific value of 2500J / kg-3000J / kg.

[0065] The sweet potato flour residue is obtained by extracting the starch from the sweet potato, drying it until the water content is less than 20%, and then crushing it into a powder less than 20 meshes.

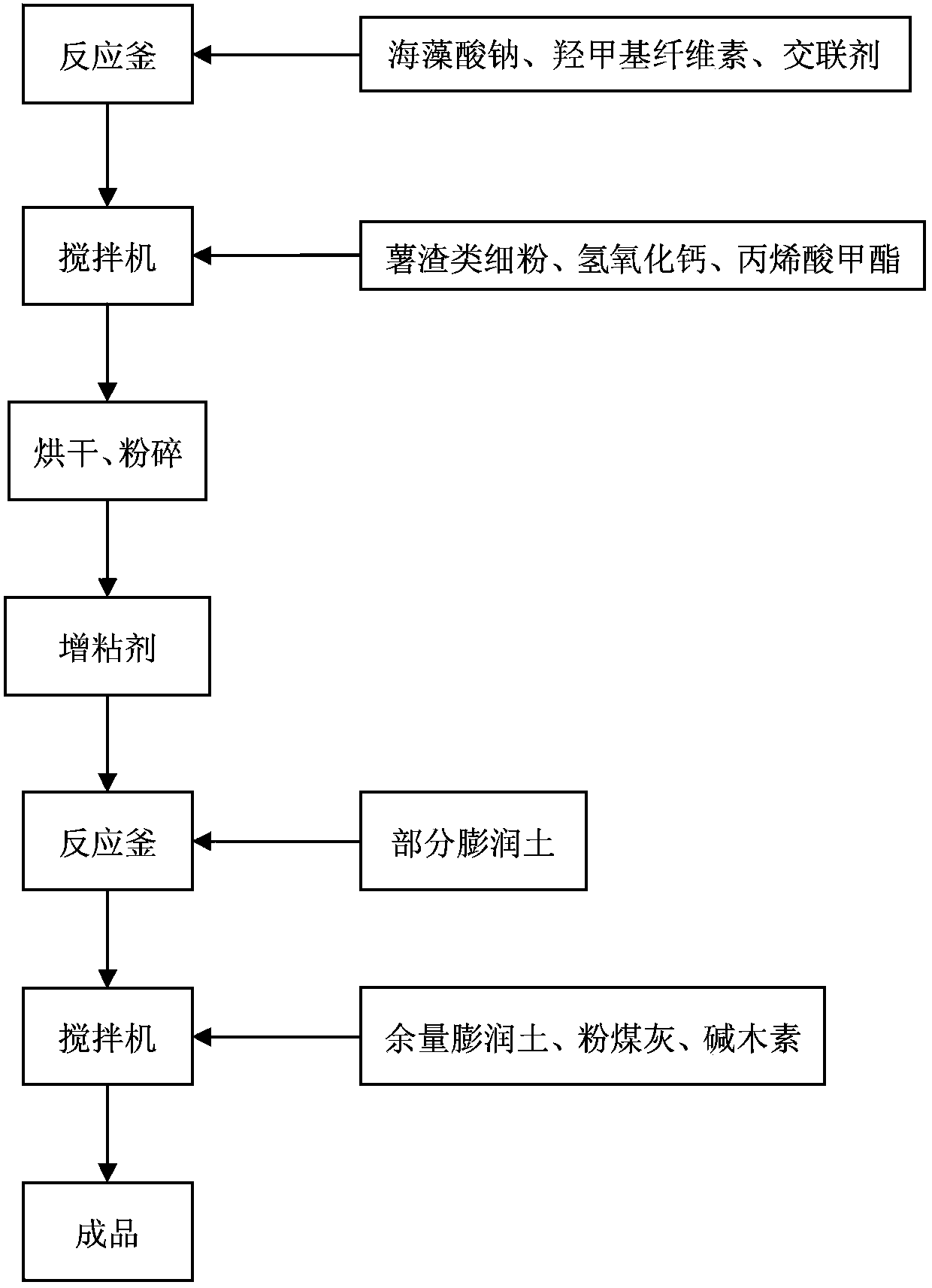

[0066] Such as figure 1 Shown, the production method of this briquette composite cross-linking binder comprises the following steps:

[0067] (1) Preparation of viscosifier According to the ratio of parts by weight, sodium alginate, hydroxymethyl cellulose and benzoyl peroxide were uniformly added to the reactor for humidification treatment, the stirring speed was 400r / min, the heating temperature was 70°C, and the...

Embodiment 2

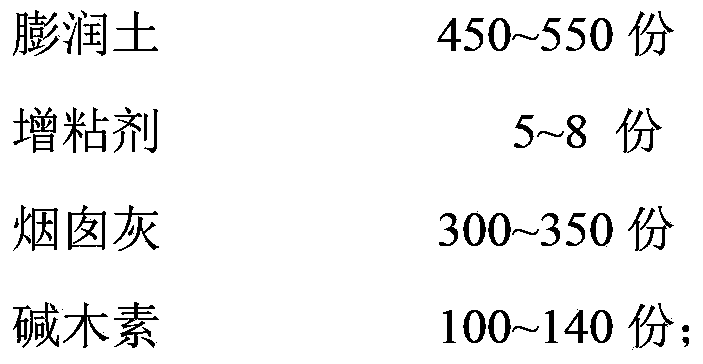

[0072] A briquette composite crosslinking binder, its raw material composition is as follows:

[0073]

[0074] Wherein, the weight ratio of each component in the tackifier is:

[0075]

[0076] The chimney ash in this embodiment is selected from the chimney and / or dust removal equipment of a chemical plant, with a calorific value of 2500J / kg-3000J / kg.

[0077] Cassava flour slag is obtained by extracting starch from cassava, drying it until the water content is less than 20%, and then crushing it into a powder less than 20 meshes.

[0078] Such as figure 1 Shown, the production method of this briquette composite cross-linking binder comprises the following steps:

[0079] (1) Preparation of viscosity enhancer According to the ratio of parts by weight, sodium alginate, hydroxymethyl cellulose and benzoyl peroxide were uniformly added to the reactor for humidification treatment, the stirring speed was 500r / min, the heating temperature was 80°C, and the reaction After 3...

Embodiment 3

[0084] A kind of briquette composite cross-linking binder, its raw material composition is as follows:

[0085]

[0086]

[0087] Wherein, the weight ratio of each component in the tackifier is:

[0088]

[0089]The chimney ash in this embodiment is selected from the chimney and / or dust removal equipment of a chemical plant, with a calorific value of 2500J / kg-3000J / kg.

[0090] The taro powder dregs is obtained by extracting the starch from the taro, drying it until the water content is less than 20%, and then crushing it into a powder less than 20 meshes.

[0091] Such as figure 1 Shown, the production method of this briquette composite cross-linking binder comprises the following steps:

[0092] (1) Preparation of viscosifier According to the ratio of parts by weight, sodium alginate, hydroxymethyl cellulose and benzoyl peroxide were uniformly added to the reactor for humidification treatment, the stirring speed was 600r / min, the heating temperature was 90°C, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heating value | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com