Method for carrying out room-temperature chemical nickel plating on modified magnesium-based surface with micro-arc oxidation porous membrane

A technology of micro-arc oxidation and electroless nickel plating, which is applied in the direction of liquid chemical plating, anodic oxidation, coating, etc., can solve the problems of decreased stability of the plating solution, affecting the quality of the plating layer, shortening the service life of the plating solution, and increasing the surface area The effect of surface energy, low cost, and less defects such as pores

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] step 1

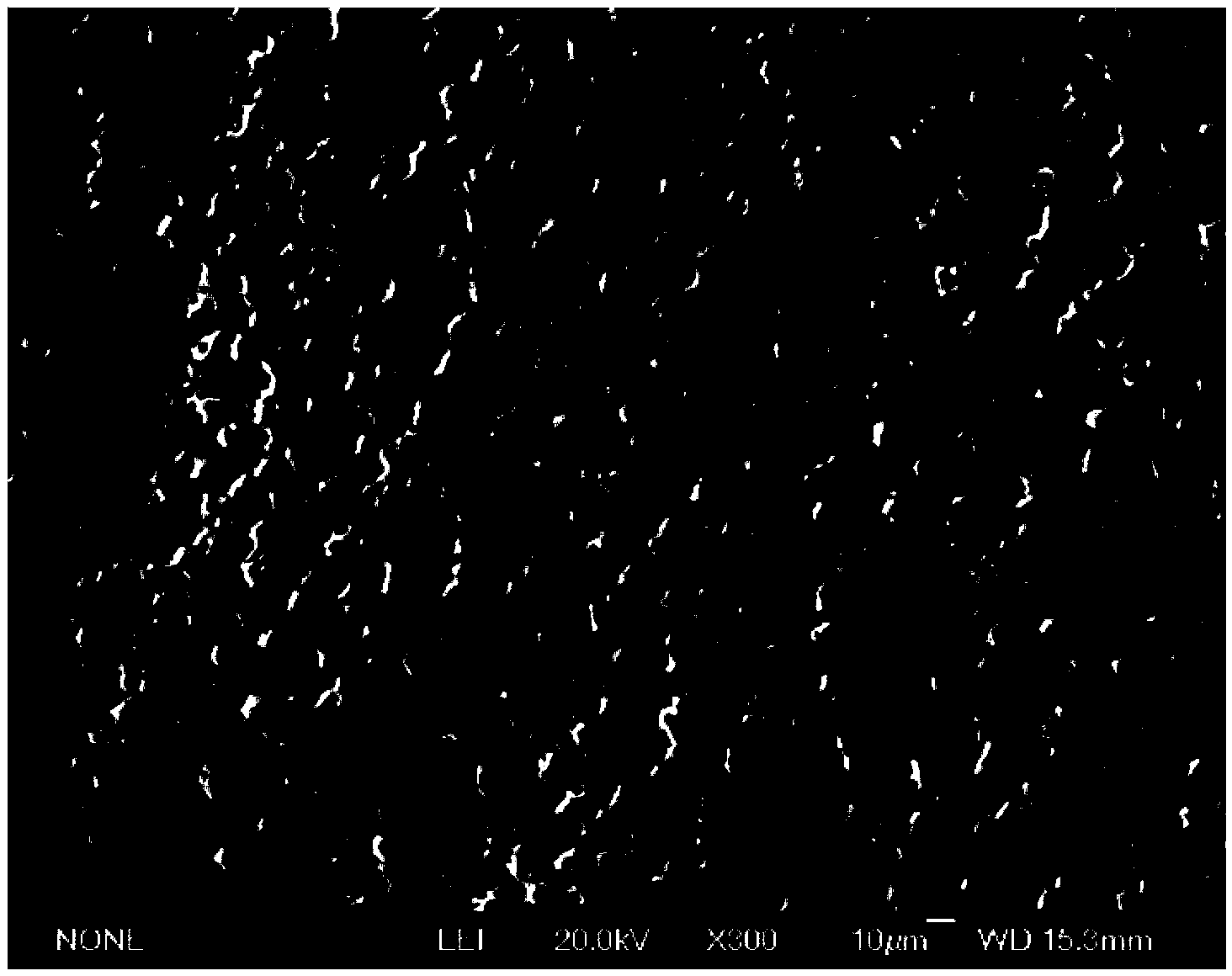

[0039] The MAO65-Ⅱ micro-arc oxidation equipment was used, and the constant pressure mode was selected to carry out micro-arc oxidation treatment on magnesium-based substrates. During the treatment process, the AZ91 magnesium alloy plate with a size of 300mm×200mm×10mm was placed in the micro-arc oxidation electrolyte prepared by sodium silicate and deionized water with a concentration of 21g / L, in which the magnesium alloy plate was used as the anode and the cathode was stainless steel Insulation protection between the cathode and anode. The micro-arc oxidation treatment parameters were voltage 420V, frequency 550Hz, duty cycle 19%, and treatment time 15min. Thus, on the magnesium-based surface, such as figure 1 The MAO porous membrane is shown.

[0040] step 2

[0041]The magnesium-based substrate after the micro-arc oxidation treatment in Step 1 was sensitized in a stannous chloride solution with a concentration of 10 g / L for 10 minutes, and then taken o...

Embodiment 2

[0045] step 1

[0046] First prepare the micro-arc oxidation electrolyte, the electrolyte contains sodium fluoride 10g / L, and the solvent is deionized water. Then, the AM60 magnesium alloy wheel plate is placed in the electrolyte for micro-arc oxidation treatment. The process parameters are voltage 470V, frequency 500Hz, duty cycle 6%, and treatment time 5min. Other details of the micro-arc oxidation process are the same as step 1 in the first embodiment.

[0047] step 2

[0048] The sensitizing solution is a 10g / L stannous chloride solution, and all the other steps are the same as step 2 in Example 1.

[0049] step 3

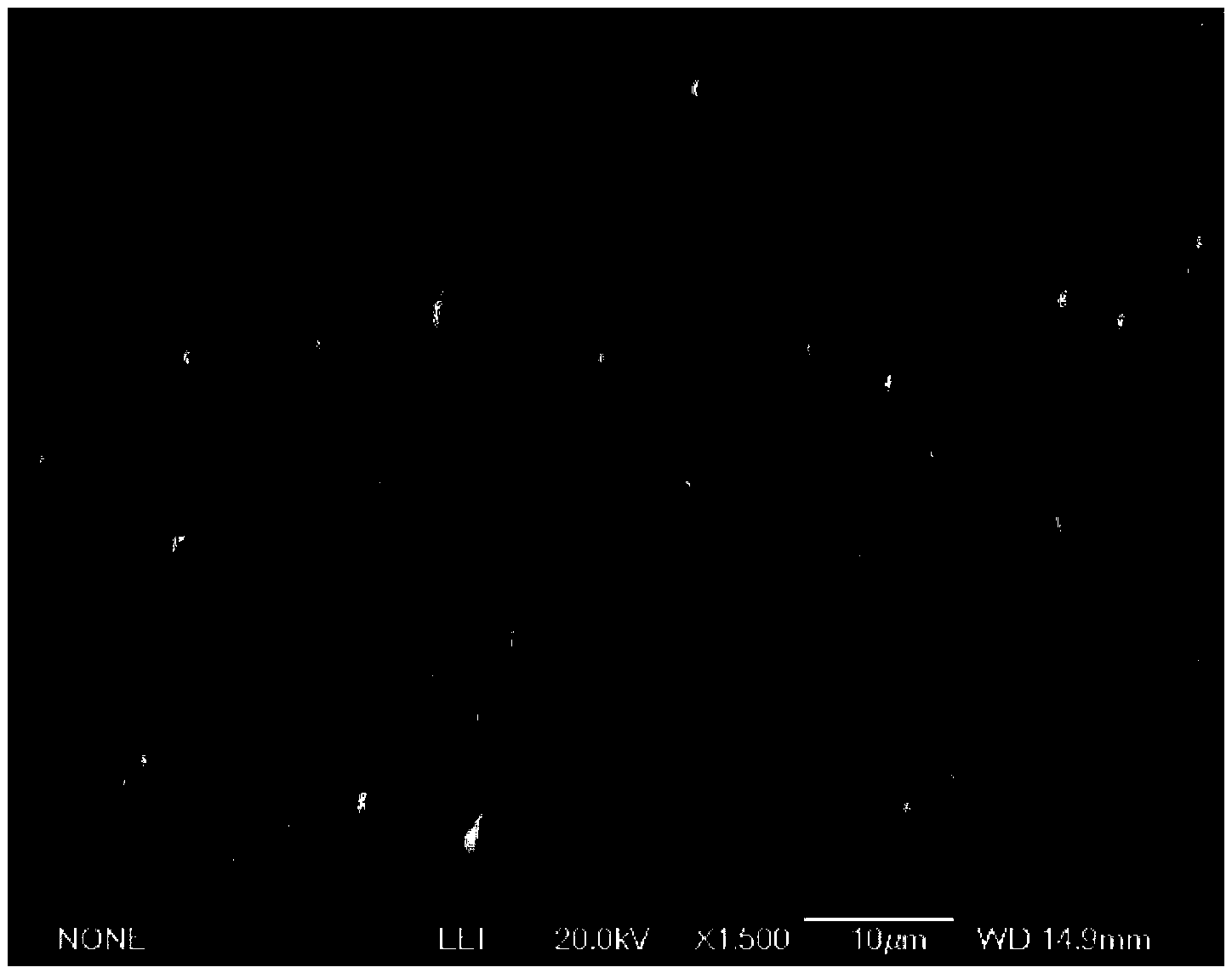

[0050] Prepare an electroless nickel plating solution at room temperature, its composition is nickel sulfate 26g / L, sodium hypophosphite 15g / L, lactic acid 28g / L, pH value about 4.6, using deionized water as solvent. The magnesium-based substrate treated in step 2 is placed in a continuously stirred plating solution for 60 minutes to deposit a nickel layer,...

Embodiment 3

[0052] step 1

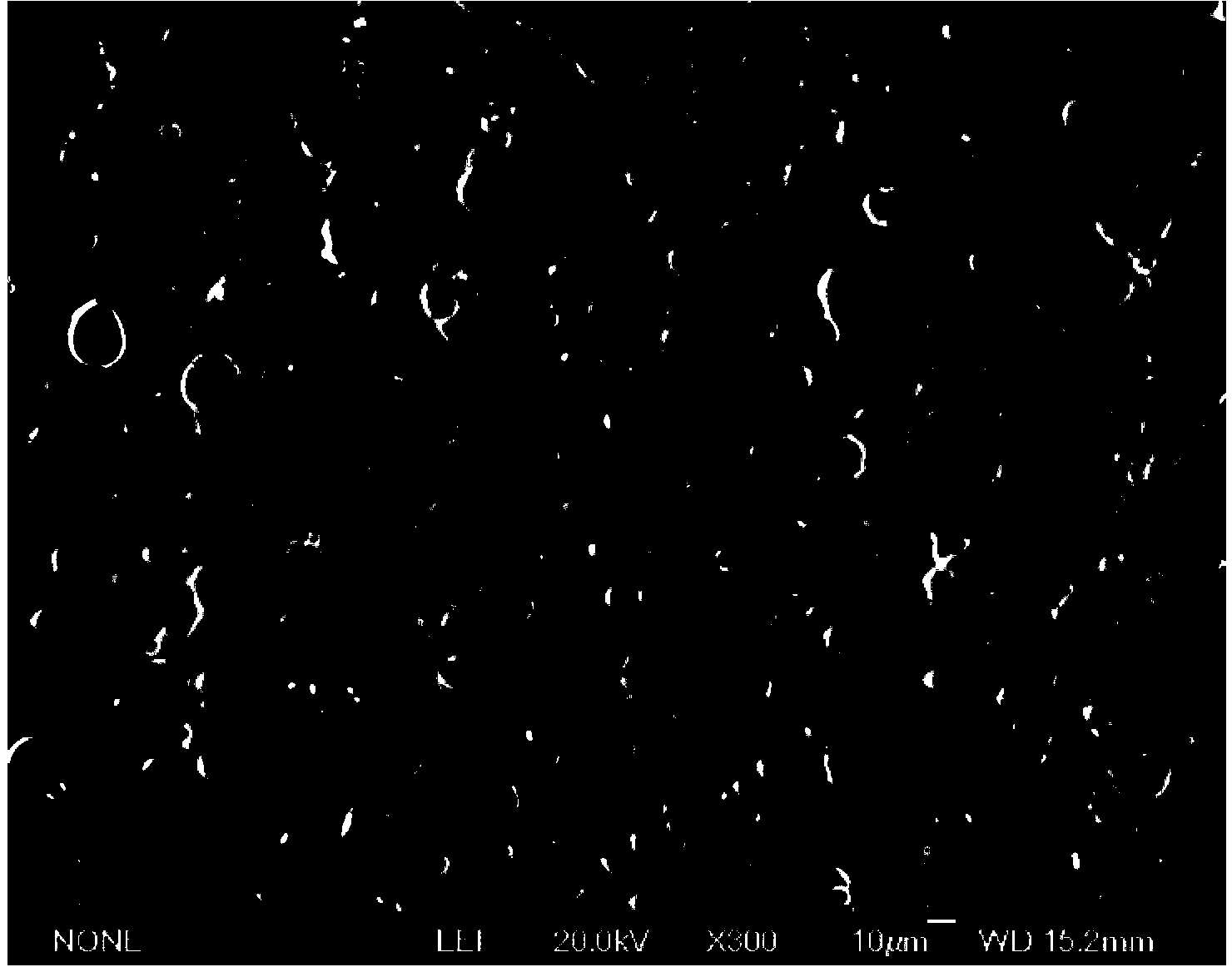

[0053] A complex porous micro-arc oxidation film with a mixed distribution of large and small pores was synthesized on the surface of a thin ZK60 magnesium alloy sheet, and the size of the sheet was Ф120mm×4mm. Continue to place the plate in 13g / L sodium phosphate solution for short-time micro-arc oxidation treatment to obtain a local macroporous structure film layer; the micro-arc oxidation treatment parameters are voltage 440V, frequency 500Hz, duty cycle 17%, treatment time 10min . Other process details are the same as in step 1 in the first embodiment. Finally, on the surface of the magnesium alloy, such as image 3 The MAO porous membrane is shown.

[0054] step 2

[0055] The sensitizing solution is a 11g / L stannous chloride solution, and all the other steps are the same as step 2 in Example 1.

[0056] step 3

[0057] First prepare the electroless nickel plating solution at room temperature. The composition of the plating solution is nickel sulfat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| corrosion potential | aaaaa | aaaaa |

| corrosion potential | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com