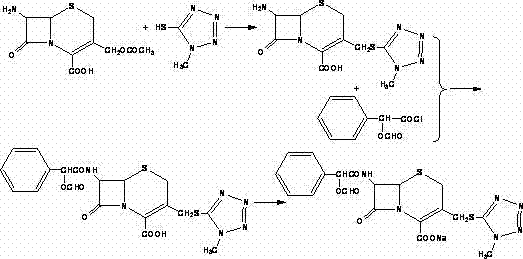

Preparation process of cefamandole nafate

The technology of a kind of cefamandole sodium and the preparation process is applied in the field of medicine, which can solve the problems of poor fineness of cefamandole sodium, increase of production cost, low total yield, etc., and achieve high yield, easy realization and low impurity content. little effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0019] (1) Pump 184L of acetonitrile into the 500L reactor, add 28.75kg of 7-aminocephalosporanic acid and 13.5kg of mercaptotetrazolium into the reactor, rinse the wall of the kettle with 5L of acetonitrile, lower the system temperature to 5°C, and then pump Add 132.25L of boron trifluoride acetonitrile as a catalyst, flush the pipeline with 5L of acetonitrile, raise the temperature of the system to 28-32°C and stir the reaction for 3 hours, cool the system to 0-5°C, and input the solution in the system through a feeding pump or vacuum pump Put it into another 1000L reactor with 210L of deionized water at 5°C, stir for 30 minutes until cloudy, add 60L of 10% ammonia water dropwise at 0-5°C to make the pH of the system 2.4-2.6, and stir for 60 minutes , centrifuged and filtered to obtain crystals, the crystals were washed three times with 80L of acetonitrile and water with a volume ratio of 7:3, three times with 80L water, and three times with 80L acetone. ℃, dried for 8 hours...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com