Medical radiation-resistant polyvinyl chloride resin

A polyvinyl chloride resin and polyvinyl chloride powder technology, which is applied in the field of medical radiation-resistant polyvinyl chloride resin, can solve the problems of large material damage, high density, and high energy, achieve good mechanical properties, reduce decomposition, and improve The effect of radiation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

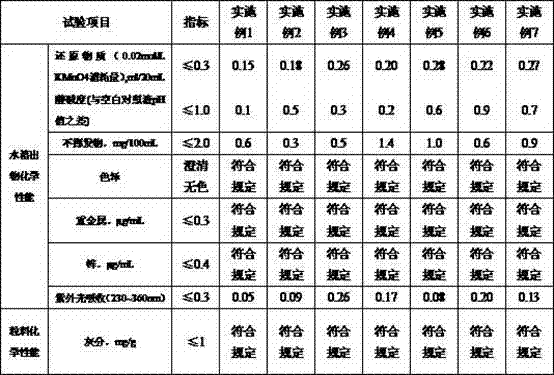

Examples

preparation example Construction

[0025] The preparation method of the medical radiation-resistant polyvinyl chloride material of the present invention comprises the following steps:

[0026] (1) Add the powdery substances in the above raw materials into a hot mixing device with a high-speed agitator with a cold mixing and hot mixing device for mixing, and add other liquid additives for mixing when the temperature reaches 80°C;

[0027] (2) After adding the liquid additive, when the temperature reaches 110°C, put the premix in the hot mixing device into the cold mixing device of the agitator and stir to room temperature to obtain the premix;

[0028](3) Add the premix obtained in step (2) to the screw extruder for melting and plasticization. The temperature of the screw extruder along the direction from the feed port to the die is 110-170°C. The temperature is 160-170°C, and the screw speed is 30-150 rpm.

[0029] (4) The blend is plasticized by a screw, extruded by a die, then subjected to hot cutting, granu...

Embodiment 1

[0030] Example 1: 100 parts of polyvinyl chloride powder, 49 parts of plasticizer diisooctyl phthalate, 1 part of high-efficiency calcium zinc stabilizer, main antioxidant β-(3,5-di-tert-butyl- 0.2 parts of 4-hydroxyphenyl) n-octadecanyl propionate, 0.5 parts of bis(2,4-di-tert-butylphenol) pentaerythritol diphosphite, 3 parts of epoxidized soybean oil 0.1 part of calcium stearate, 0.1 part of zinc stearate, and 0.1 part of medical silicone oil.

Embodiment 2

[0031] Example 2: 100 parts of polyvinyl chloride powder, 55 parts of plasticizer cyclohexane-1,2-diisononyl dicarboxylate, 0.5 parts of high-efficiency calcium zinc stabilizer, main antioxidant β-(3 , 0.2 parts of 5-di-tert-butyl-4-hydroxyphenyl) n-octadecyl propionate 0.2 parts, phosphite auxiliary antioxidant bis(2,4-di-tert-butylphenol) pentaerythritol disulfide Phosphate ester 0.05 part, epoxy soybean oil 5 part, calcium stearate 0.15 part, zinc stearate 0.15 part, medical silicone oil 0.05 part.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com