Laser direct writing type nanometer periodic structure pattern manufacturing equipment

A periodic structure and laser direct writing technology, applied in microlithography exposure equipment, optics, optical components, etc., can solve the problems of accumulating considerable processing errors, low process reliability, and slow processing speed, etc. High height, good feedback effect, miniaturized heating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

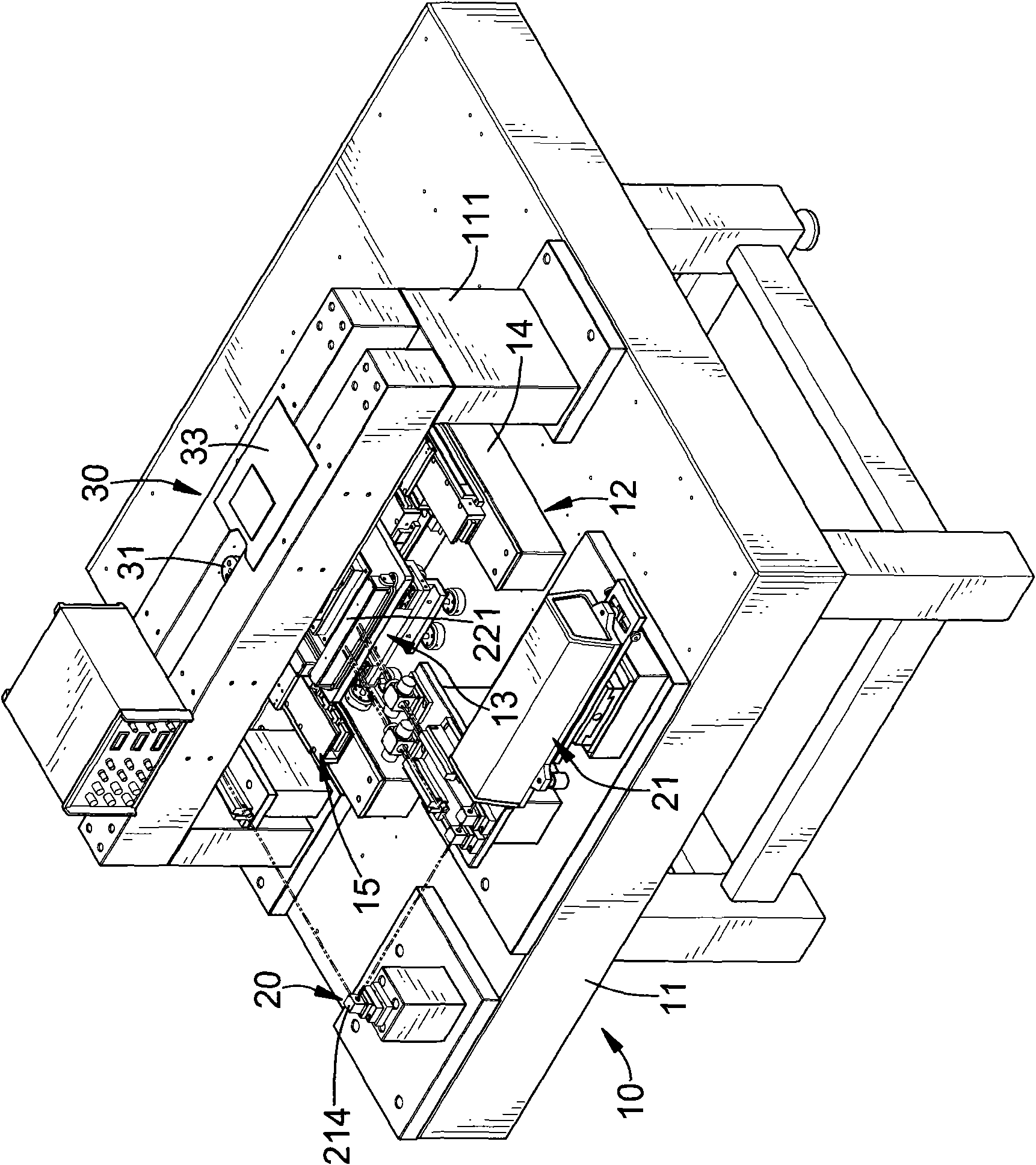

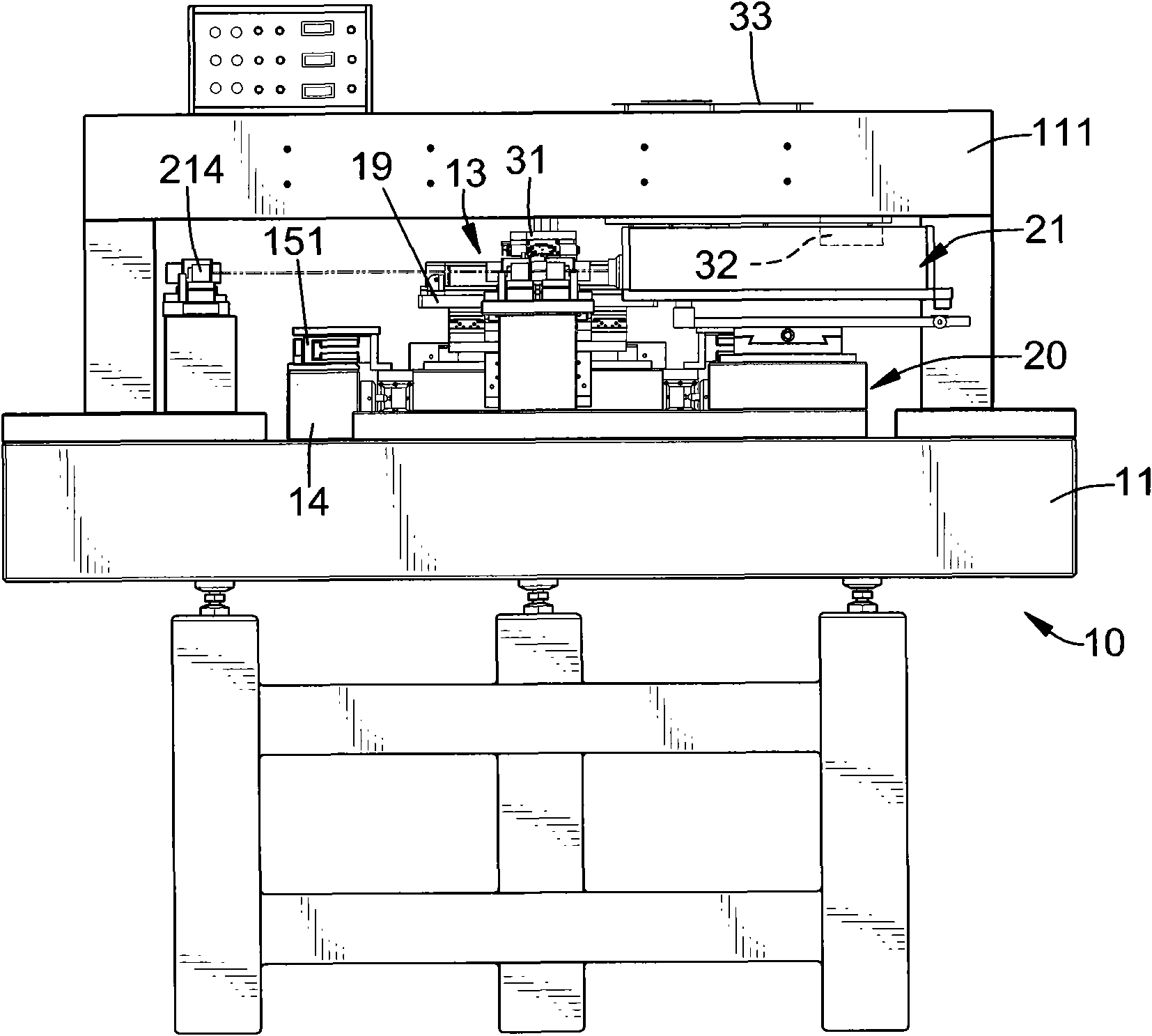

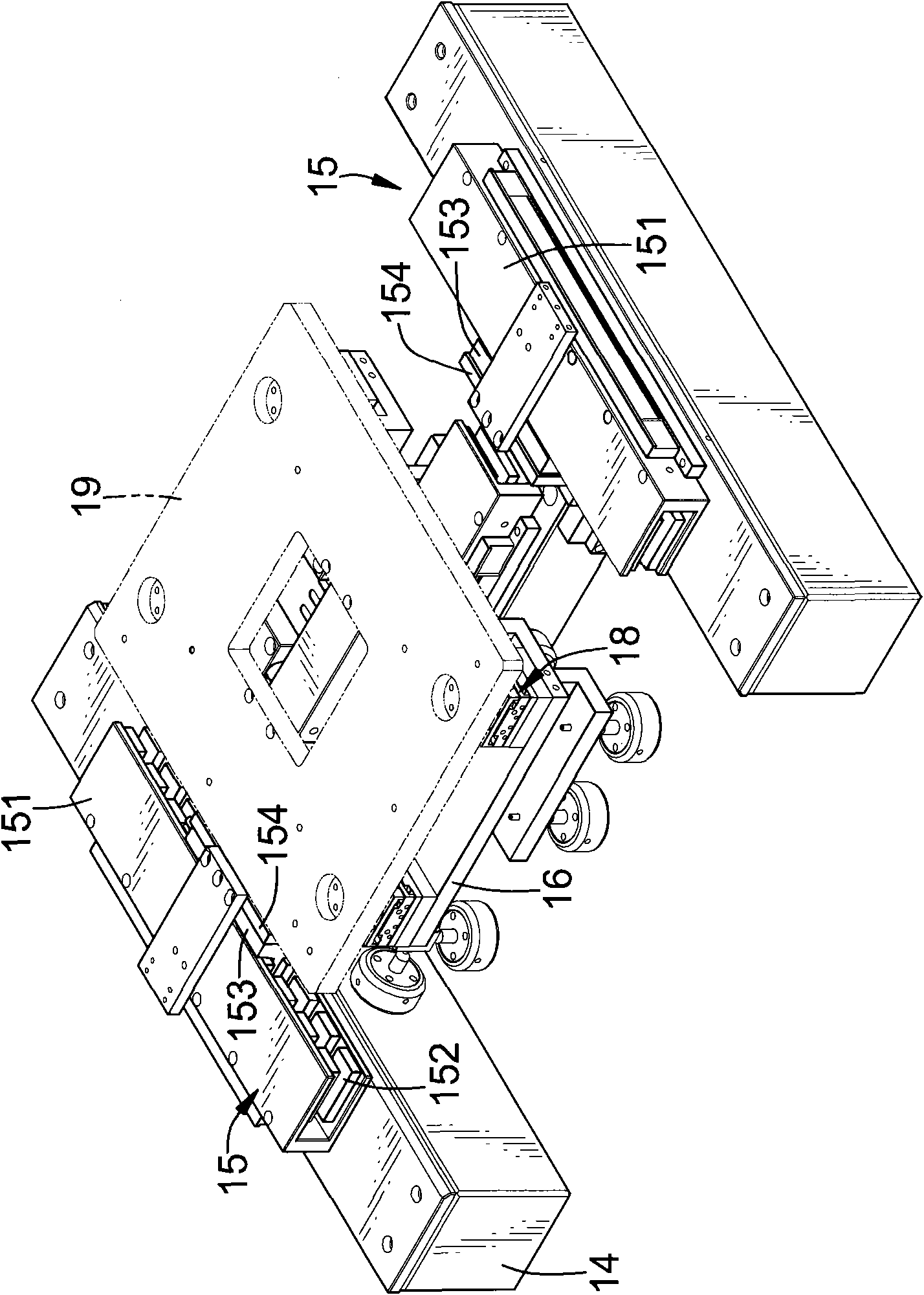

[0025] In order to understand the technical characteristics and practical effects of the present invention in detail, and to implement them according to the contents of the description, further drawings (such as Figures 1 to 4 Shown) the preferred embodiment shown in detail is as follows:

[0026] The present invention provides a laser direct writing nano-periodic structure pattern manufacturing equipment, which includes a platform group 10, a measurement feedback group 20 and a laser direct writing head group 30, wherein:

[0027] The platform set 10 is provided with a base 11 and a hybrid mobile platform, wherein the base 11 is provided with a combination frame 111 horizontally on the top surface, and the hybrid mobile platform is provided with a long-stroke mobile platform 12 and a micro-motion piezoelectric platform 13 The long-stroke mobile platform 12 is movably arranged on the top surface of the base 11 and is located below the joint frame 111 and is provided with a re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com