Novel technique for preparing long-chain alkane efficiently through multifunctional catalyst in one-step method

A technology of long-chain alkanes and catalysts, which is applied in the field of one-step preparation of liquid fuels from biomass derivatives with multifunctional catalysts, and can solve the problems of low energy efficiency, harsh reaction conditions, and low selectivity of long-chain alkanes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

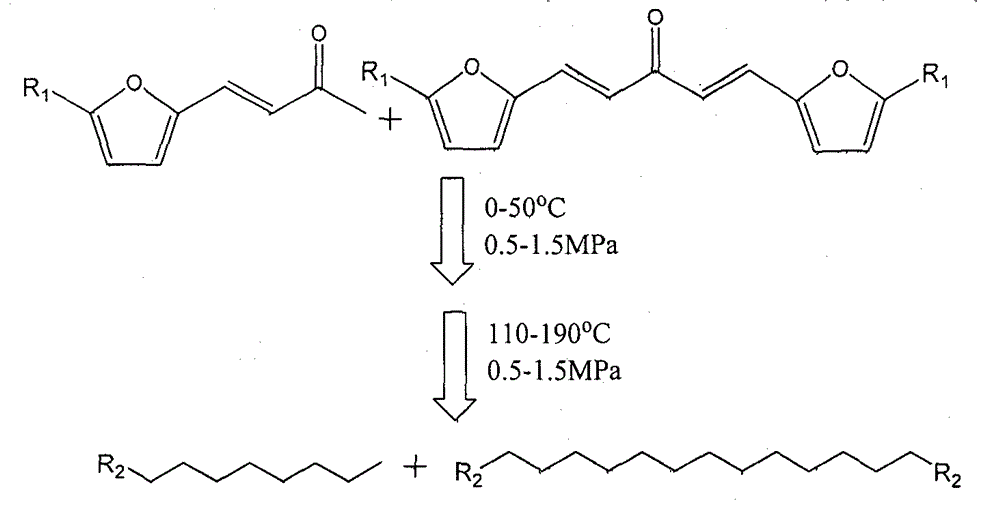

Method used

Image

Examples

Embodiment 1

[0016] 0.4g C8 (4-(2-furyl)-3-butene-2-one) and 6g solvent tetrahydrofuran are dropped into a batch type autoclave with 50ml polytetrafluoroethylene liner, then add 0.1g Pd / Nb 2 o 5 Multifunctional catalyst, at 15°C, under 1.0MPa hydrogen pressure, high-speed stirring, react for 10min, then raise the temperature to 170°C to continue the reaction for 16h, C 8The conversion was 100% and the octane yield was 97%.

Embodiment 2

[0018] 1.0g C 9 (4-(5-hydroxymethyl-2-furyl)-3-butene-2-one) and 6g solvent methanol drop into the intermittent autoclave with 50ml polytetrafluoroethylene liner, then add 0.4g Ru / WO 3 Catalyst, at 40°C, under 1.5MPa hydrogen pressure, high-speed stirring, react for 3h, then raise the temperature to 150°C to continue the reaction for 24h, C 9 The conversion was 100%, the yield of nonane was 51%, and the rest was mainly some intermediate products with one oxygen remaining.

Embodiment 3

[0020] 0.5g C 13 (1,5-bis(2-furyl)-1,4-pentadien-3-ketone) and 6g solvent dichloromethane drop into the intermittent autoclave with 50ml polytetrafluoroethylene liner, then add Multifunctional Catalyst Pt / ZrOSO 4 0.2g, at 25°C, under 0.8MPa hydrogen pressure, high-speed stirring, react for 1h, then raise the temperature to 190°C to continue the reaction for 4h, C 13 The conversion rate is 100%, the yield of tridecane is 82%, and a small amount of other alkanes are produced due to carbon-carbon breakage.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com