Preparation method of polycarbonate powder

A technology of polycarbonate and a manufacturing method, which is applied in the field of manufacturing polycarbonate powder from polycarbonate solution, can solve the problems of affecting product quality, uneven polycarbonate powder, difficulty in recovering residual solvent, etc., and achieves the recovery rate High performance, mild operating conditions, simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

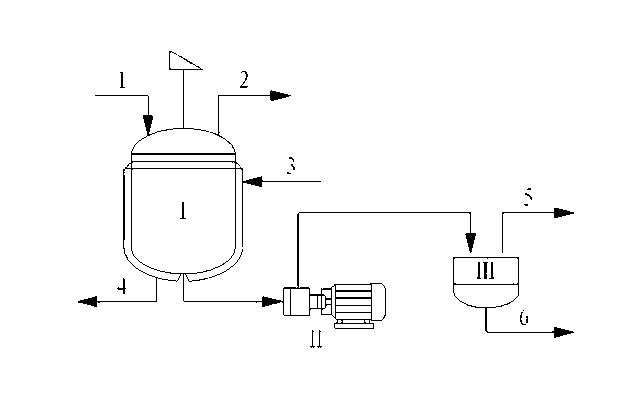

Method used

Image

Examples

Embodiment 1

[0032] (1) In a 100L stirred tank, first add 60kg of deionized water, the stirring speed is 500 rpm, and then add 1.2kg of polycarbonate powder with an average particle size of 1.5mm and a number average molecular weight of 21000; (2) After the temperature rises to 53°C, 58kg of polycarbonate solution with a mass fraction of 14.5% and a number average molecular weight of 21,000 is added dropwise for 1 hour, and methylene chloride is recovered at the same time; (3) After the addition, the temperature of the material Raise it to 85°C for 2 hours, and recover dichloromethane at the same time; (4) The slurry is first pulverized with a pulverizing pump with a gap of 4mm between the rotary mill and the fixed mill, and then centrifugally separated at a speed of 1500 rpm Machine for solid-liquid separation to obtain polycarbonate wet powder and mother liquor, and the mother liquor is used to manufacture the next batch of polycarbonate powder; (5) Dry polycarbonate wet powder at 125°C f...

Embodiment 2

[0035] (1) In a 100L stirred tank, first add 60kg of deionized water, the stirring speed is 500 rpm, and then add 0.9kg of polycarbonate powder with an average particle size of 1.5mm and a number average molecular weight of 27000; (2) After the temperature rises to 55°C, 50kg of polycarbonate solution with a mass fraction of 14.5% and a number average molecular weight of 27,000 is added dropwise for 1 hour, and methylene chloride is recovered at the same time; (3) After the addition, the temperature of the material Raise it to 90°C, desolventize for 2 hours, and recover dichloromethane at the same time; (4) The slurry is first pulverized with a pulverizing pump with a gap of 4mm between the rotary mill and the fixed mill, and then centrifuged with a speed of 1500 rpm The separator performs solid-liquid separation to obtain polycarbonate wet powder and mother liquor, and the mother liquor is used to manufacture the next batch of polycarbonate powder; (5) The polycarbonate wet po...

Embodiment 3

[0038](1) In a 100L stirred tank, first add 60kg of the mother liquor in Example 2, the stirring speed is 600 rpm, and then add 0.9kg of polycarbonate powder with an average particle size of 1.5mm and a number average molecular weight of 27000; (2 ) After the temperature of the material rises to 53°C, add 82.5kg of polycarbonate solution with a mass fraction of 14.5% and a number average molecular weight of 27,000 dropwise for 1.5 hours, while recovering dichloromethane; (3) after the dropwise addition , the temperature of the material was raised to 85°C, the precipitation was carried out for 1.5 hours, and dichloromethane was recovered at the same time; (4) The slurry was first crushed with a crushing pump with a gap of 4 mm between the rotary mill and the fixed mill, and then the slurry was crushed with a speed of 1500 rpm Separate the centrifuge for solid-liquid separation to obtain polycarbonate wet powder and mother liquor, and the mother liquor is used to manufacture the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bulk density | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com