Method for preparing hydroxy apatite biological ceramic coating containing fluorine

A technology of fluorine-containing hydroxyapatite and bioceramics, which is applied in coatings, metal material coating processes, etc., can solve the problems of fast decomposition rate, poor long-term stability of hydroxyapatite, and low bonding strength of coatings, achieving The effect of high bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

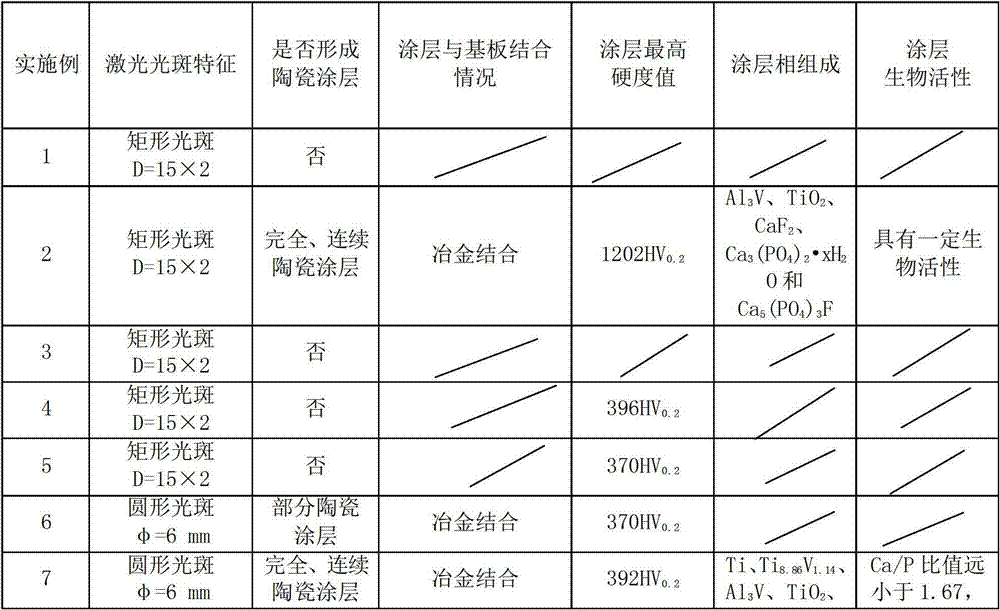

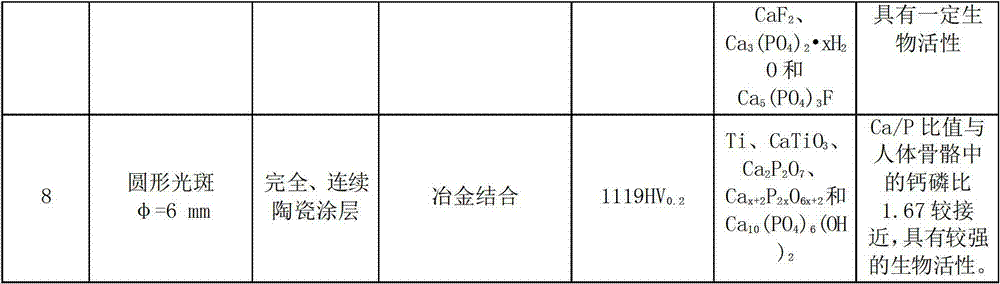

Examples

example 1

[0035] (1) Uniformly mix 2.3% by weight calcium fluoride powder and 97.7% hydroxyapatite powder; specifically, mix the above powders together, use a ball mill to refine the mixed powder and mix evenly ,

[0036] (2) Use polyvinyl alcohol solution with a concentration of 2% as a binder to prepare mixed powder;

[0037] (3) Preset the prepared mixed powder on the titanium alloy substrate. Specifically, use a manual spray gun and an air compressor to spray the mixed powder on the surface of the titanium alloy substrate to form a preset coating. The thickness of the coating is 0.3mm.

[0038] (4) A carbon dioxide laser is used to perform broadband laser cladding on titanium alloy substrates to generate fluorine-containing hydroxyapatite bioceramic coatings. The process parameters used in the cladding process are: laser output power P=0.5kW, scanning speed V=200mm / min, spot size D=15mm×2mm, and argon gas protection. At this time, due to the low laser power, the laser energy abso...

example 2

[0040] (1) Uniformly mix 2.3% by weight calcium fluoride powder and 97.7% hydroxyapatite powder; specifically, mix the above powders together, use a ball mill to refine the mixed powder and mix evenly ,

[0041] (2) Use polyvinyl alcohol solution with a concentration of 2% as a binder to prepare mixed powder;

[0042] (3) Preset the prepared mixed powder on the titanium alloy substrate. Specifically, use a manual spray gun and an air compressor to spray the mixed powder on the surface of the titanium alloy substrate to form a preset coating. The thickness of the coating is 0.3mm.

[0043] (4) A carbon dioxide laser is used to perform broadband laser cladding on titanium alloy substrates to generate fluorine-containing hydroxyapatite bioceramic coatings. The process parameters used in the cladding process are: laser output power P=0.7kW, scanning speed V=200mm / min, spot size D=15mm×2mm, and argon gas protection. At this time, a continuous coating is formed on the surface of ...

example 3

[0045] (1) Uniformly mix 2.3% by weight calcium fluoride powder and 97.7% hydroxyapatite powder; specifically, mix the above powders together, use a ball mill to refine the mixed powder and mix evenly ,

[0046] (2) Use polyvinyl alcohol solution with a concentration of 2% as a binder to prepare mixed powder;

[0047] (3) Preset the prepared mixed powder on the titanium alloy substrate. Specifically, use a manual spray gun and an air compressor to spray the mixed powder on the surface of the titanium alloy substrate to form a preset coating. The thickness of the coating is 0.3mm.

[0048] (4) A carbon dioxide laser is used to perform broadband laser cladding on titanium alloy substrates to generate fluorine-containing hydroxyapatite bioceramic coatings. The process parameters used in the cladding process are: laser output power P=1kW, scanning speed V=200mm / min, spot size D=15mm×2mm, and argon gas protection. At this time, due to the high laser power, the coating ripples ar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| microhardness | aaaaa | aaaaa |

| microhardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com