Preparation method for Fe3S4 nanocrystalline material

A nanocrystalline material, fe3s4 technology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of complex precursor preparation, poor stability, complex synthesis conditions, etc. The effect of size controllable, good crystallinity and good crystallinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] The invention provides a Fe 3 S 4 The preparation method of nanocrystalline material comprises the following steps:

[0042] A) Mix the iron source compound and β-cyclodextrin in ethylene glycol, and heat to obtain a suspension;

[0043] B) Mix and react the suspension with a sulfur source compound to obtain Fe 3 S 4 nanocrystalline material.

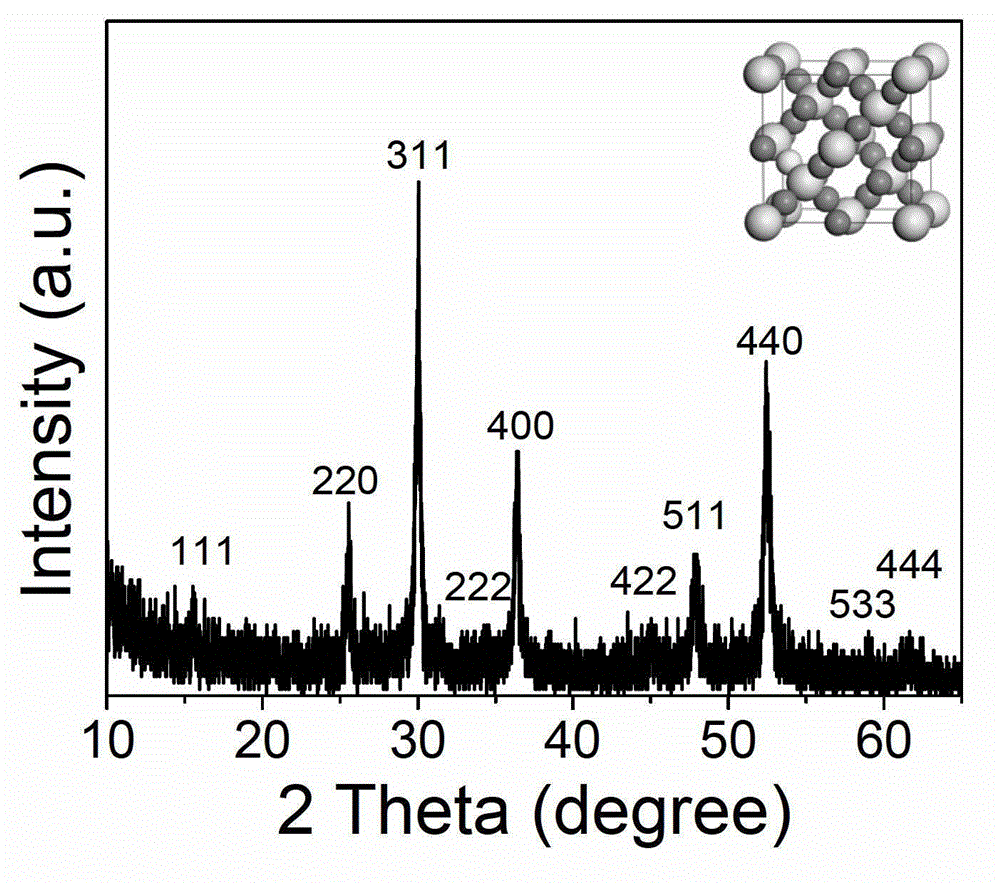

[0044] In the present invention, the iron source compound and β-cyclodextrin are first mixed in ethylene glycol, heated to obtain a suspension, and then the suspension is mixed with the sulfur source compound to obtain Fe 3 S 4 nanocrystalline material. The present invention uses ethylene glycol as a solvent and β-cyclodextrin as a surfactant to prepare Fe 3 S 4 Nanocrystalline materials have good crystallinity, stability, water solubility and biocompatibility. The encapsulation of β-cyclodextrin makes Fe 3 S 4 The surface of nanocrystalline materials has a very thin protective layer, similar to biological magnetosomes...

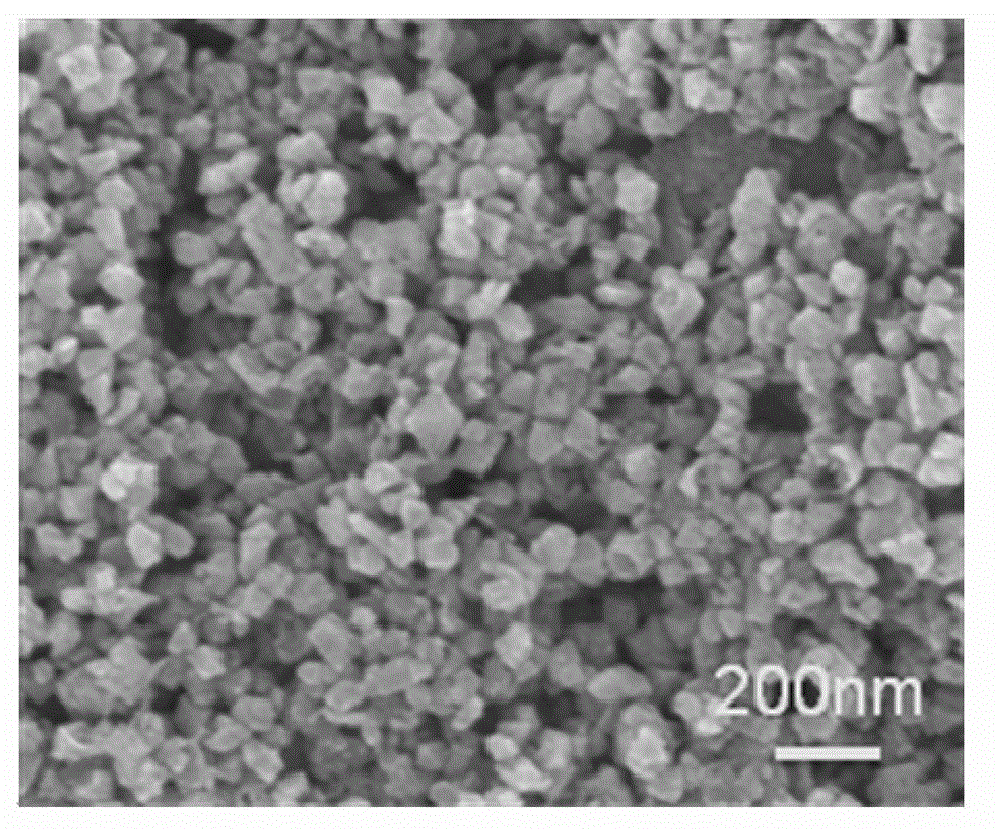

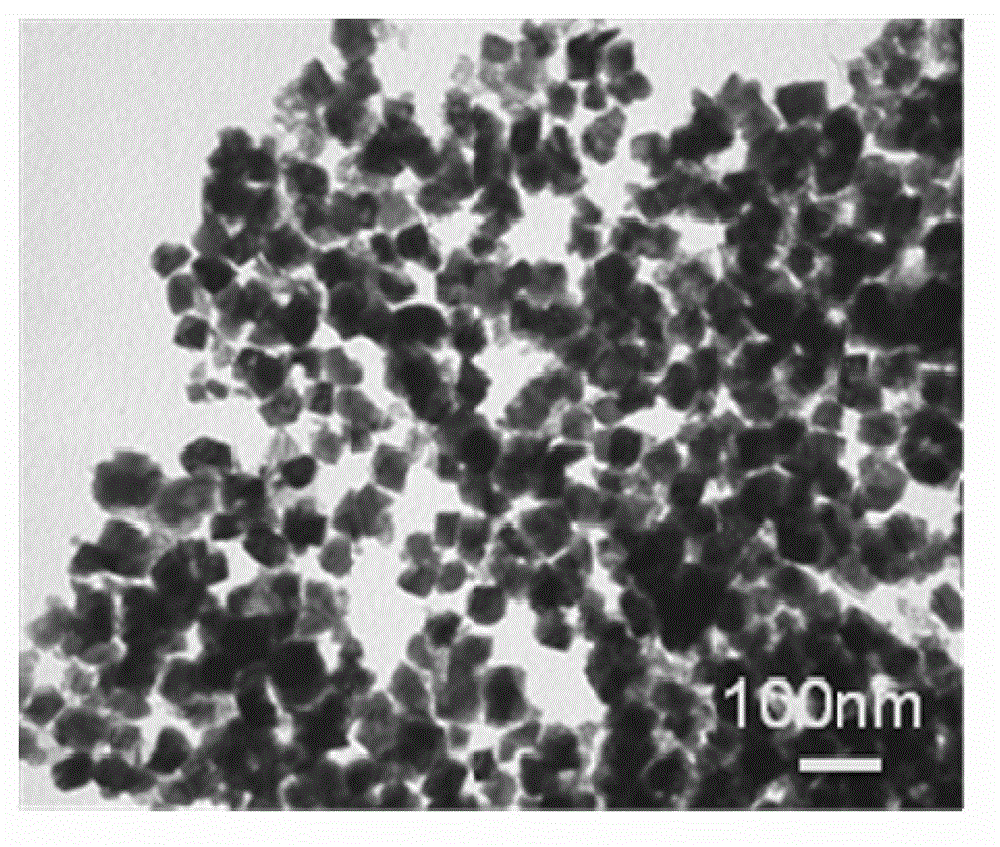

Embodiment 1

[0059] Dissolve 0.0260g (0.35mmol) of thioacetamide in 5mL of ethylene glycol solvent until fully dissolved to obtain an ethylene glycol solution of thioacetamide; under nitrogen protection, dissolve 0.0883g (0.25mmol) of iron acetylacetonate , 0.25mmol β-cyclodextrin and 0.5mmol polyethylene glycol with a number average molecular weight of 4000 were dissolved in 20mL of ethylene glycol solvent, heated to 160°C and kept for reaction until the reaction mixture turned into a turbid yellow suspension , adding the ethylene glycol solution of thioacetamide to it, and immediately obtained a suspension containing a large amount of black precipitate, which was stirred and reacted at 160°C for 2 hours to obtain Fe 3 S 4 nanocrystal suspension, then the reaction system was cooled to 60°C and the Fe 3 S 4 The black precipitate in the nanocrystal suspension was centrifuged and magnetically separated, then washed 3 times with deionized water, and then vacuum freeze-dried to obtain Fe 3 ...

Embodiment 2

[0068] Dissolve 0.0260g (0.35mmol) of thioacetamide in 5mL of ethylene glycol solvent until fully dissolved to obtain an ethylene glycol solution of thioacetamide; under nitrogen protection, dissolve 0.0883g (0.25mmol) of iron acetylacetonate Dissolve 0.25mmol β-cyclodextrin (β-CD) in 20mL ethylene glycol solvent, raise the temperature to 160°C and keep it warm for reaction. When the reaction mixture turns into a turbid yellow suspension, add thioethyl The ethylene glycol solution of amide immediately obtained a suspension containing a large amount of black precipitate, which was stirred and reacted at 160°C for 2 hours to obtain Fe 3 S 4 nanocrystal suspension, then the reaction system was cooled to 60°C and the Fe 3 S 4 The black precipitate in the nanocrystal suspension was centrifuged and magnetically separated, then washed 3 times with deionized water, and then vacuum freeze-dried to obtain Fe 3 S 4 nanocrystalline material.

[0069] get Fe 3 S 4 After the nanocrys...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com