Hydrophobic MMA (Methl Methacrylate) resin floor coating and preparation method thereof

A technology of floor coating and hydrophobicity, applied in the direction of coating, etc., can solve the problems of poor environmental performance, poor hydrophobicity of MMA flooring, high cost, etc., and achieve low production cost, excellent mechanical properties and hydrophobicity of the coating film, Effect of low additive content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A preparation method of fluorine-containing acrylate resin: add 60g of deionized water, 0.05g of nano silicon dioxide and 0.03g of sodium nitrite into a four-necked flask, stir at 200rpm to completely dissolve it, and wait until the temperature reaches After 50°C, add dropwise a uniform mixed solution consisting of 1g perfluoroalkylethyl methacrylate, 3g xylene and 0.38g azobisisobutyronitrile. There is a mixed solution of 0.12 g of azobisisobutyronitrile, 5 g of methyl methacrylate, and 0.2 g of isopropanol. Stir the reaction at a speed of 200 rpm for 2 h, then cool down to room temperature and discharge to obtain the product perfluoroalkylethyl methacrylate-methyl methacrylate copolymer.

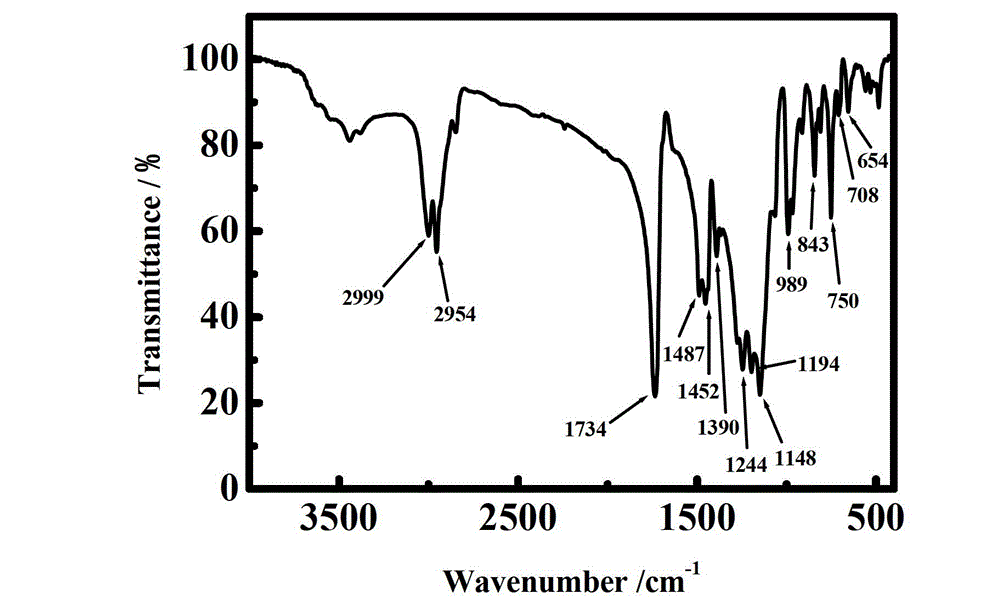

[0031] The FTIR spectrogram of embodiment 1 product perfluoroalkyl ethyl methacrylate-methyl methacrylate copolymer, as figure 1 shown. 2960~2860cm -1 It is the C-H stretching vibration absorption peak of methyl and methylene, 1487cm -1and 1390cm -1 They are the shear vibration...

Embodiment 2

[0034] A preparation method of fluorine-containing acrylate resin: Add 70g of deionized water, 0.07g of magnesium hydroxide and 0.04g of sodium sulfite into a four-neck flask, stir at 200rpm to completely dissolve it, and wait until the temperature reaches 85°C , add dropwise a uniform mixed solution composed of 8g 2-(perfluorodecyl)ethyl methacrylate, 4.5g butyl acetate and 0.5g azobisisoheptanonitrile, and after the dropwise reaction is carried out for 15min, add additional drops A mixed solution of 0.2 g of azobisisoheptanonitrile, 20 g of methyl methacrylate, and 0.3 g of isopropanol was dissolved. Stir the reaction at a speed of 300 rpm for 5 h, then cool down to room temperature and discharge to obtain the product 2-(perfluorodecyl)ethyl methacrylate-methyl methacrylate copolymer.

Embodiment 3

[0036] A preparation method of fluorine-containing acrylate resin: add 75g of deionized water, 0.085g of polyvinyl alcohol and 0.05g of hydroquinone into a four-necked flask, stir at 200rpm to completely dissolve it, and wait until the temperature reaches 90 After ℃, add dropwise a uniform mixed solution composed of 16g hexafluorobutyl acrylate, 6g 1,2-propylene glycol methyl ether and 1g dimethyl azobisisobutyrate. There is a mixed solution of 0.2 g of dimethyl azobisisobutyrate, 28 g of methyl methacrylate, and 0.4 g of n-hexanethiol. Stir the reaction at a speed of 400 rpm for 8 hours, then cool down to room temperature and discharge to obtain the product hexafluorobutyl acrylate-methyl methacrylate copolymer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Static water contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com