Shaddock peel water-soluble dietary fiber beverage and production process

A technology of dietary fiber and production process, applied in food science and other directions, to achieve the effects of reducing pollution, high concentration and increasing flavor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

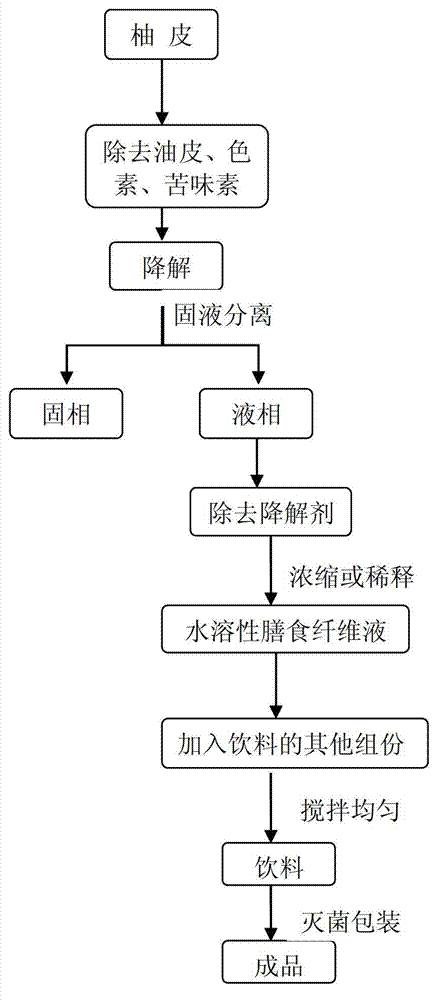

Method used

Image

Examples

Embodiment 1

[0033] Take fresh pomelo peel to remove the surface oil skin, and add 40°C saturated and clarified Ca(OH) to the pomelo peel with a solid-to-liquid mass ratio of 1:5 2 Soak in aqueous solution for 5 hours, then wash twice with clean water, squeeze dry water powder to get the first dry residue, soak the first dry residue in 60°C water for 60 minutes, squeeze the water to get the second dry residue, the second dry residue Soak in water at 50°C for 40 minutes, wash with clean water, squeeze out the water to obtain pomelo peel residue, add pomelo peel residue and degradation agent sodium carbonate to the water at a solid-to-liquid mass ratio of 1:4, and the amount of sodium carbonate added 3% of the quality of pomelo peel slag, degrade at a temperature of 95°C for 1 hour; filter after the degradation is complete, and add dilute hydrochloric acid with a concentration of 8% to the resulting filtrate, the amount of dilute hydrochloric acid being equal to that of sodium carbonate Reac...

Embodiment 2

[0035] Take the fresh pomelo peel to remove the surface oil skin, put the pomelo peel with the removed oil skin into the lime emulsion at a solid-to-liquid mass ratio of 1:4 and soak for 8 hours. 2 :H 2Prepared at a mass ratio of O=1:3, at a temperature of 30°C, then washed with clean water for 3 times, squeezed out the water to obtain the first dry slag, soaked in 60°C water for 50 minutes, squeezed out the water, Obtain the second dry residue, soak the second dry residue in water at 50°C for 60 minutes, wash with clean water, squeeze out the water to obtain pomelo peel residue, add pomelo peel residue and degradation agent sodium carbonate at a solid-to-liquid mass ratio of 1:5 In water, the amount of sodium carbonate added is 5% of the pomelo peel quality, and the degradation is carried out at a temperature of 90°C for 1.5 hours; after the degradation is completed, filter, and add dilute hydrochloric acid with a concentration of 10% to the obtained filtrate, dilute hydrochl...

Embodiment 3

[0037] Take fresh pomelo peel and remove the surface oil skin, add the pomelo peel with a solid-to-liquid mass ratio of 1:6 into warm water at a temperature of 50°C and soak for 2 hours, squeeze out the water to obtain the first dry residue, which is pressed The mass ratio of solid to liquid is 1:5, add water at a temperature of 60°C and soak for 60 minutes, squeeze out the water to obtain the second dry slag, then wash 3 times with clean water, squeeze out the water to obtain pomelo peel slag, mix pomelo peel slag and degradation agent carbonic acid Sodium was added into water at a solid-to-liquid mass ratio of 1:5, wherein the amount of sodium carbonate added was 4% of the mass of pomelo peel residue, and the degradation was carried out at a temperature of 93°C for 2 hours; Adding concentration is the calcium acetate solution of 7.5% in, the addition of calcium acetate is to react with sodium bicarbonate, generates the theoretical dosage of sodium acetate, obtains pomelo peel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com